Morinda citrifolia extract and application thereof to preparation of drugs for controlling plant anthracnose

A technology of extract and noni fruit, applied in noni fruit extract and its application in the preparation of medicines for preventing and treating plant anthracnose, plant active extract and its application field, achieving the effect of simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

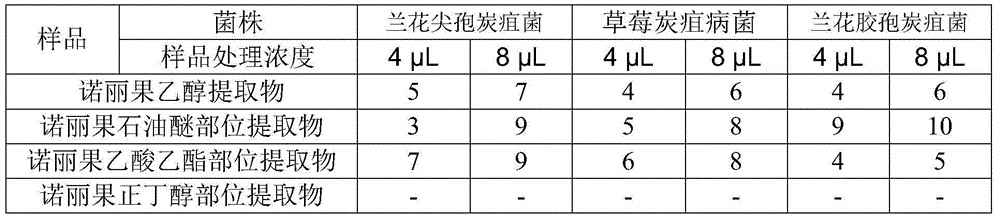

Image

Examples

Embodiment 1

[0013] Squeeze fresh ripe noni fruit juice, filter it with 4 layers of gauze, centrifuge at 4000r / min for 20min, and the supernatant is noni juice. Noni juice was freeze-dried into powder by freeze dryer, leached 3 times with 95% ethanol ultrasonic (ultrasonic frequency 40kHz, temperature 30°C, time 20min), combined the extracts for suction filtration, and the filtrate was passed through a vacuum rotary evaporator (Water bath temperature 45 ℃) concentrated into extractum to obtain Noni fruit ethanol extract.

Embodiment 2

[0015] Squeeze fresh ripe noni fruit juice, filter it with 4 layers of gauze, centrifuge it at 5000r / min for 15min, and the supernatant is noni juice. Noni juice was freeze-dried into powder by freeze dryer, leached three times with 95% ethanol ultrasonic (ultrasonic frequency 40kHz, temperature 32°C, time 30min), combined the extracts for suction filtration, and the filtrate was passed through a vacuum rotary evaporator (Water bath temperature 45 ℃) concentrated into extractum to obtain Noni fruit ethanol extract. Add 2 times the volume of noni ethanol extract in distilled water to make a suspension, extract with an equal volume of petroleum ether (boiling range 60-90°C) of the suspension, and concentrate the extraction phase with a vacuum rotary evaporator to obtain noni petroleum ether site extract.

Embodiment 3

[0017] Squeeze fresh ripe noni fruit juice, filter it with 4 layers of gauze, centrifuge it at 5000r / min for 10min, and the supernatant is noni juice. Noni juice was freeze-dried into powder by freeze dryer, leached three times with 95% ethanol ultrasonic (ultrasonic frequency 40kHz, temperature 34°C, time 40min), combined the extracts for suction filtration, and the filtrate was passed through a vacuum rotary evaporator (Water bath temperature 45 ℃) concentrated into extractum to obtain Noni fruit ethanol extract. Add 2 times the volume of noni ethanol extract in distilled water to make a suspension, extract with ethyl acetate equal to the volume of the suspension, and concentrate the extract phase by a vacuum rotary evaporator to obtain the extract of noni ethyl acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com