Crispy biscuit and making method thereof

A kind of crisp biscuit and mixing technology, applied in baking, dough processing, baked food and other directions, can solve the problems of single taste, cost saving, oily or hard taste, etc., to avoid hard taste and reduce raw materials. Cost, the effect of avoiding oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

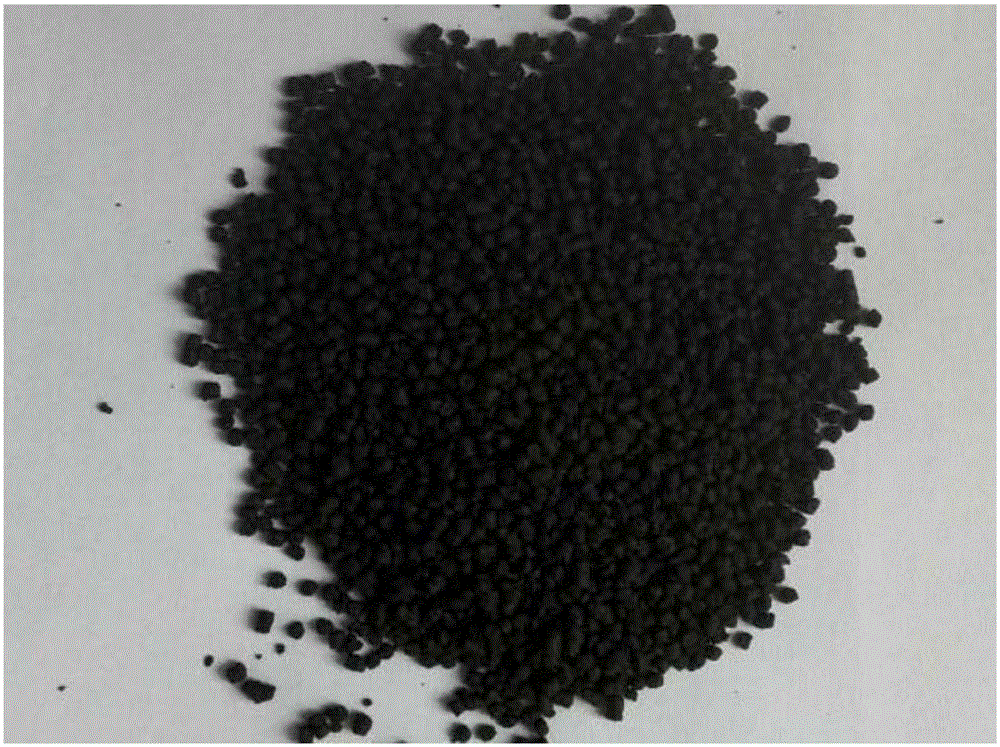

Image

Examples

Embodiment 1

[0027] The crisp biscuit of this embodiment is made of the following raw materials in parts by weight: 100 parts of wheat flour, 22 parts of palm oil, 32 parts of white granulated sugar, 12 parts of water, 7.5 parts of cocoa powder, 1.4 parts of edible salt, and 0.6 part of sodium bicarbonate , 0.3 parts of vanillin, 0.6 parts of caramel color, and 0.05 parts of chocolate essence.

[0028] The specific operation steps of its preparation method are:

[0029] 1) Powder adjustment: Mix wheat flour, white sugar, cocoa powder, edible salt, sodium bicarbonate, caramel color, and vanillin for 3 minutes until uniform, and obtain mixture A, which is set aside; add chocolate essence to the preheated to 45°C Stir in palm oil evenly to obtain mixture B, which is set aside; mix mixture A and mixture B for 3 minutes until uniform, and obtain mixture C; add water to mixture C, mix and stir for 4 minutes until uniform, and obtain wet powder;

[0030] 2) Forming: The wet powder prepared in st...

Embodiment 2

[0035] The crisp biscuit of this embodiment is made of the following raw materials in parts by weight: 90 parts of wheat flour, 20 parts of palm oil, 30 parts of white granulated sugar, 10 parts of water, 6 parts of cocoa powder, 0.8 part of edible salt, and 0.3 part of sodium bicarbonate .

[0036] The specific operation steps of its preparation method are:

[0037] 1) Powder adjustment: Mix wheat flour, white sugar, cocoa powder, edible salt, and sodium bicarbonate for 2 minutes until uniform, to obtain mixture A, and set aside; preheat palm oil to 40°C, to obtain mixture B, set aside; mix A Mix and stir with mixture B for 2 minutes until uniform to obtain mixture C; add water to mixture C, and mix and stir for 3 minutes until uniform to obtain wet powder;

[0038] 2) Molding: The wet powder prepared in step 1) is extruded by twin-screw extruder and extruded by an automatic feeder, then passed through four temperature zones in sequence, extruded and extruded by a molding di...

Embodiment 3

[0041] The crisp biscuit of this embodiment is made from the following raw materials in parts by weight: 110 parts of wheat flour, 24 parts of palm oil, 40 parts of white granulated sugar, 13 parts of water, 8 parts of cocoa powder, 1.8 parts of edible salt, and 1.0 part of sodium bicarbonate , 0.5 parts of vanillin, 0.9 parts of caramel color, and 0.1 part of chocolate essence.

[0042] The specific operation steps of its preparation method are:

[0043] 1) Powder adjustment: Mix wheat flour, white sugar, edible salt, sodium bicarbonate, vanillin, cocoa powder, and caramel color for 4 minutes until uniform, and obtain mixture A, which is set aside; add chocolate essence to the Stir in palm oil evenly to obtain mixture B, and set aside; mix mixture A and mixture B for 4 minutes until uniform, and obtain mixture C; add water to mixture C, mix and stir for 5 minutes until uniform, and obtain wet powder;

[0044] 2) Molding: The wet powder prepared in step 1) is extruded by twin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com