Minimally invasive robot mirror-holding mechanical arm

A mechanical arm and robot technology, applied in the field of medical devices, can solve the problems of difficult assembly of the overall mechanism, large volume of the mechanical arm, inconvenient preoperative adjustment, etc., and achieve the effects of easy manual adjustment, small size and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

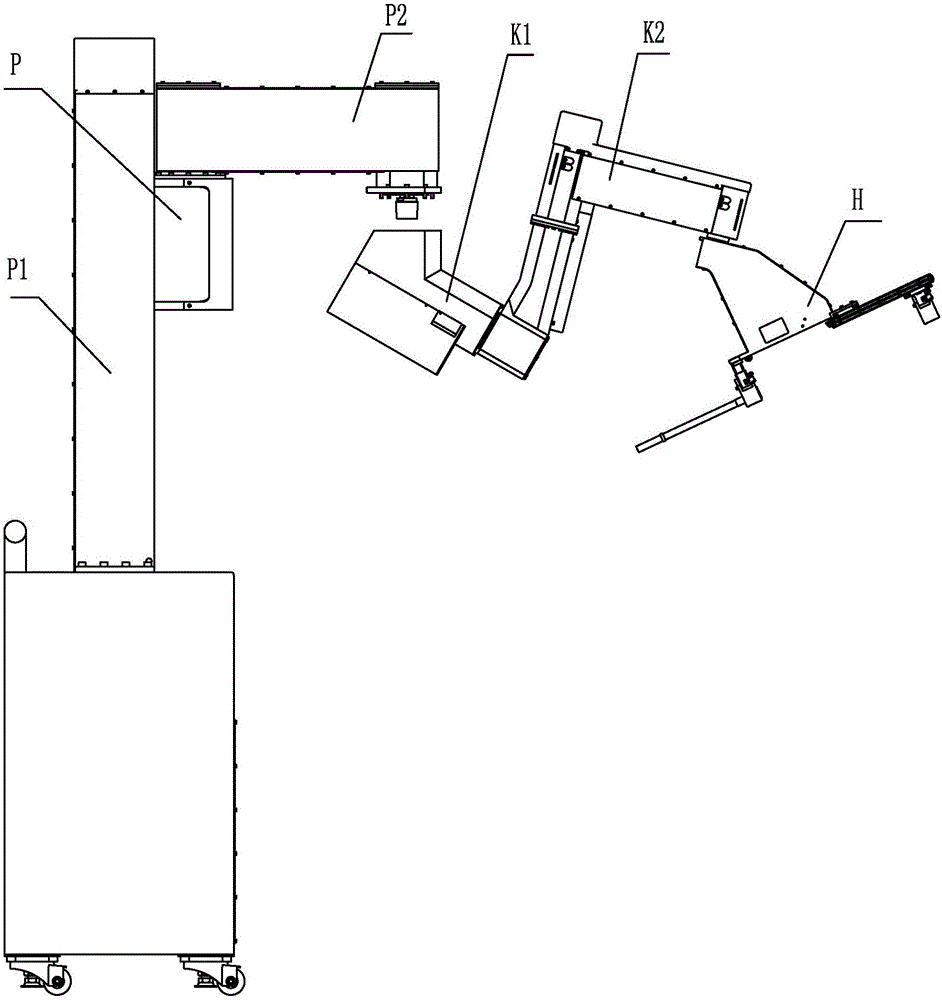

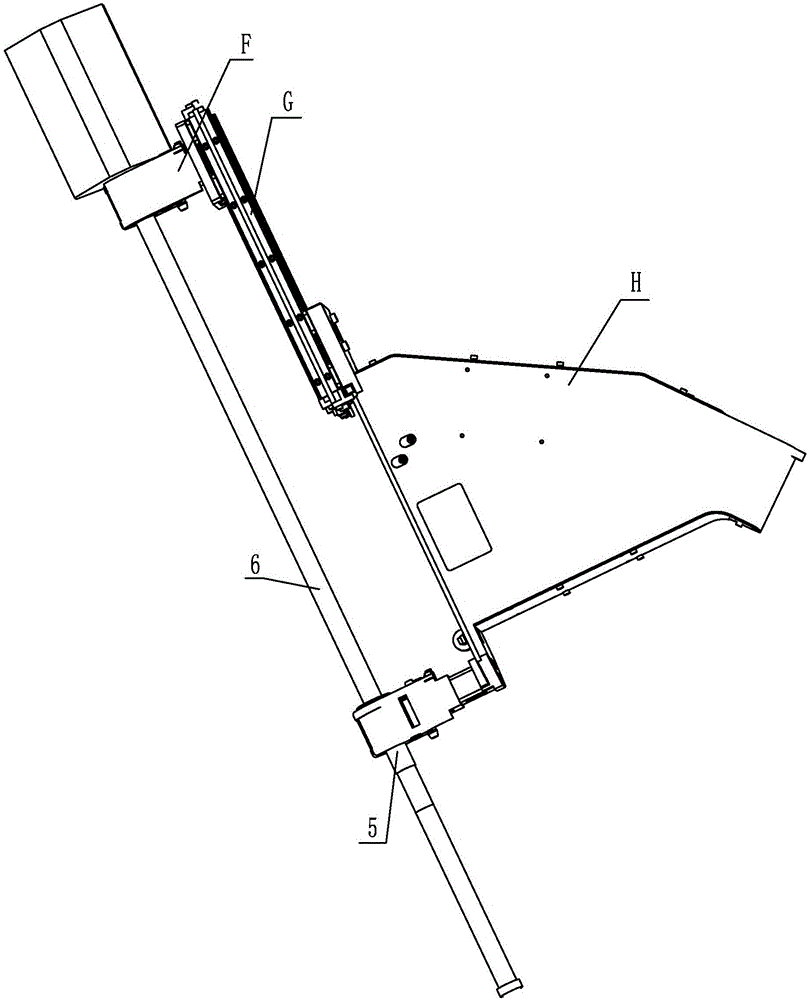

[0017] Specific implementation mode one: combine Figure 1-Figure 28 Explain that a minimally invasive robotic mirror-holding mechanical arm of this embodiment includes a passive arm P, a first joint K1, a second joint K2, and an endoscope clamping device; the passive arm P includes a vertical translation mechanism P1 and a joint connecting rod P2; the vertical translation mechanism P1 includes a base assembly 1, a guide rail assembly 2, and an outer interface connection assembly 3; the base assembly 1 includes a box body 1-1, a counterweight 1-2, and at least one optical axis assembly, at least one optical axis The assembly is arranged on the box body 1-1. The optical axis assembly includes the optical axis body 1-3 and two optical axis pressure rings 1-4, and the two optical axis pressure rings 1-4 are respectively fixedly connected to the box body 1- 1, the optical axis 1-3 passes through two optical axis pressure rings 1-4 from top to bottom and is fixedly connected in the...

specific Embodiment approach 2

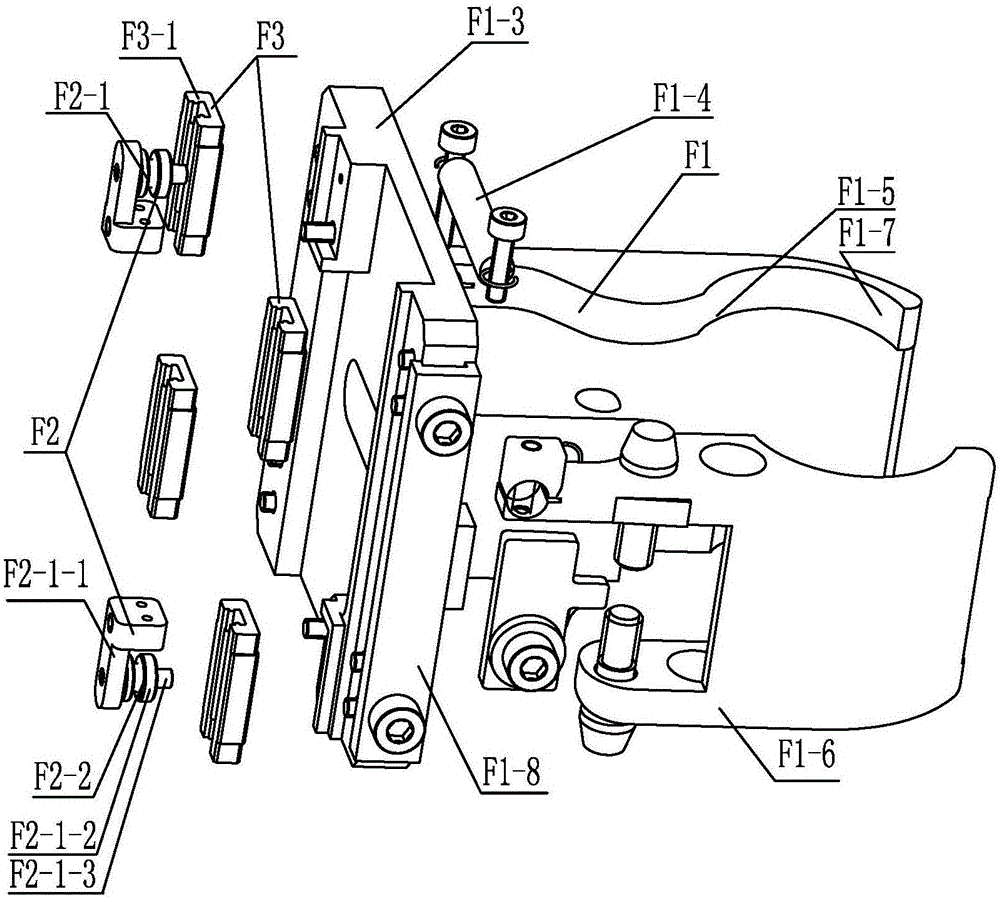

[0027] Specific implementation mode two: combination Figure 3-Figure 4 Explain that the endoscope holder F1 of this embodiment includes a clamping base F1-3, a spring F1-4, a fastening plate F1-5, a clamping movable arm F1-6 and a clamping fixed arm F1-7; A clamping fixed arm F1-7 is fixedly connected to the holding base F1-3, and a clamping movable arm F1-6 and a fastening pressure plate F1- 5. The clamping movable arm F1-6 can rotate on the clamping base F1-3, one end of the spring F1-4 is installed on the clamping movable arm F1-6, and the other end of the spring F1-4 is installed on the clamping fixed arm F1 On -7, a wedge-shaped block F1-6-1 cooperating with the fastening platen F1-5 is fixedly connected to the outer surface of the clamping movable arm F1-6, and the clamping base F1-1 of the poking clamper H3-1 3 Installed on the support frame H3-3. The clamping movable arm F1-6 of this embodiment is fixedly connected with a wedge-shaped block F1-6-1 cooperating with t...

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 9-Figure 10 Note that the poking holder H3-1 of this embodiment includes a clamping base F1-3, a spring F1-4, a fastening plate F1-5, a clamping movable arm F1-6 and a clamping fixed arm F1-7; The clamping fixed arm F1-7 is fixedly connected to the clamping base F1-3, and the clamping movable arm F1-6 and the fastening pressure plate F1 arranged in cooperation with the clamping fixed arm F1-7 are installed on the clamping base F1-3 -5, the clamping movable arm F1-6 can rotate on the clamping base F1-3, one end of the spring F1-4 is installed on the clamping movable arm F1-6, and the other end of the spring F1-4 is installed on the clamping fixed arm On F1-7, a wedge-shaped block F1-6-1 cooperating with the fastening plate F1-5 is fixedly connected to the outer surface of the clamping movable arm F1-6, and the clamping base F1 of the poking clamper H3-1 -3 is installed on the support frame H3-3. The clamping movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com