Anti-dandruff composition and preparation method thereof

A composition and anti-dandruff technology, which is applied in the field of daily chemicals, can solve the problems of short maintenance time, poor effect, and large human body irritation, and achieve the effect of good hair growth effect, low raw material cost, and high commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

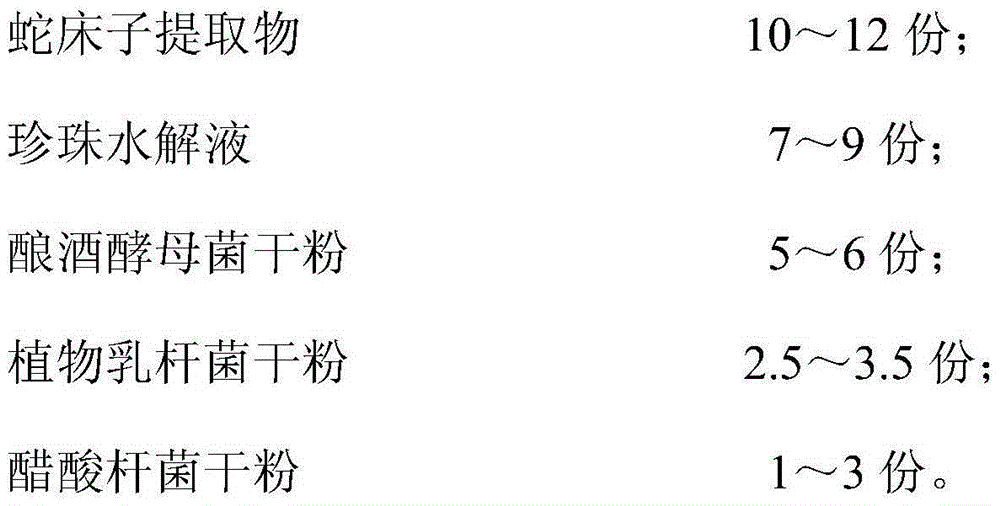

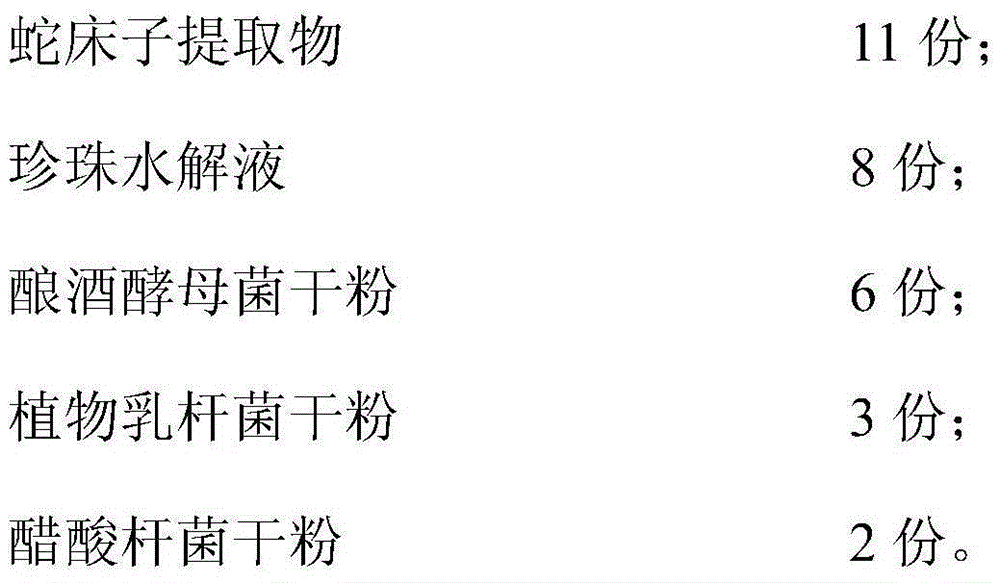

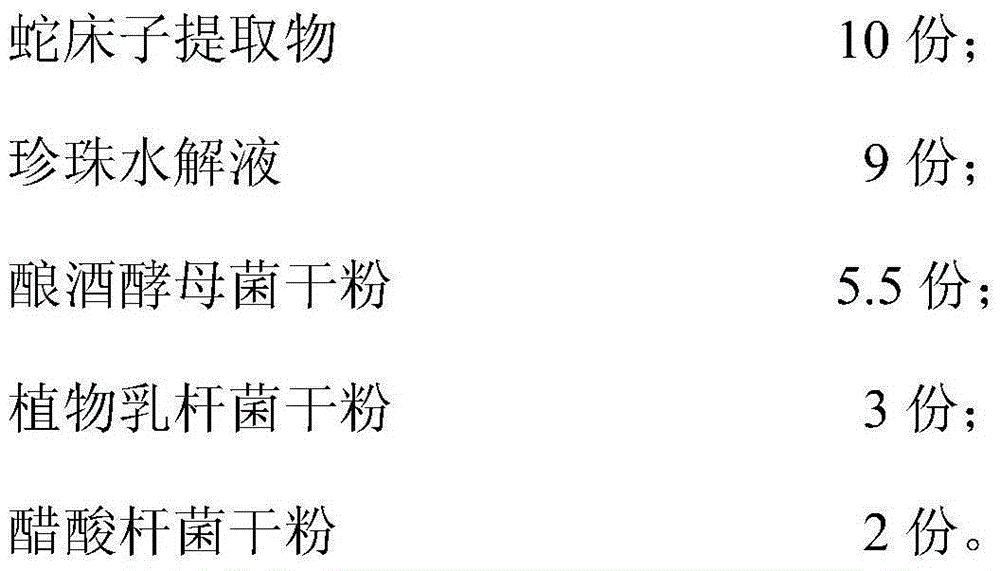

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 Fructus Cnidii Extract

[0058] The Fructus Cnidii extract of the present embodiment is prepared by the following method:

[0059] After the Fructus Cnidii is pulverized, use the ethanol solution of 50% as the extraction solution with the mass percent concentration, the solid-liquid ratio is 1:7 (g / ml), the control temperature is 40 ℃, after extracting for 6 hours, filter and collect the filtrate, the The filtrate is added to a molecular distillation apparatus for distillation. The molecular distillation conditions are vacuum degree of 15Pa, distillation temperature of 60°C, material flow rate of 2ml / min, scraper speed of 55r / min, condensate temperature of 20°C, and retain the components flowing out along the condensation column , which is the desired Cnidium Fructus Extract.

Embodiment 2

[0060] Embodiment 2 Saccharomyces cerevisiae dry powder

[0061] The saccharomyces cerevisiae dry powder of the present embodiment is prepared by the following method:

[0062] After the Saccharomyces cerevisiae strain is activated on the slant, rinse the slant with sterile physiological saline to obtain a Saccharomyces cerevisiae suspension, and the Saccharomyces cerevisiae suspension is connected to the Saccharomyces cerevisiae seed medium with an inoculation amount of 6% by volume Carry out seed culture, the seed culture condition is temperature 30 ℃, shake table culture 36h, obtain Saccharomyces cerevisiae seed liquid, this Saccharomyces cerevisiae seed liquid is inoculated in Saccharomyces cerevisiae fermentation medium with the inoculation amount of volume ratio 10%, ferment The temperature is 30°C, after 48 hours of liquid fermentation culture, the Saccharomyces cerevisiae fermentation culture liquid is obtained, the Saccharomyces cerevisiae fermentation culture liquid ...

Embodiment 3

[0070] Embodiment 3 Lactobacillus plantarum dry powder

[0071] The plantarum dry powder of the present embodiment is prepared by the following method:

[0072] After the Lactobacillus plantarum strain is cultured and activated on the slant, the slant is washed with sterile physiological saline to obtain a Lactobacillus plantarum suspension, and the Lactobacillus plantarum suspension is connected to the Lactobacillus plantarum seed medium with an inoculation amount of 3% by volume Carry out seed culture, the seed culture condition is: temperature 35 ℃, shaking table culture 30h, obtains plantarum lactobacillus seed liquid, this plantarum lactobacillus seed liquid is inoculated in plantarum lactobacillus fermentation medium with the inoculation amount of volume ratio 12%, The fermentation temperature is 36°C, after 48 hours of liquid fermentation culture, the Lactobacillus plantarum fermentation broth is obtained, the Lactobacillus plantarum fermentation broth is separated from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com