Anti-Dandruff Nourishing Shampoo

A technology of shampooing and mass-parts, which is applied in the field of daily necessities, can solve the problems that shampoo is difficult to adapt, easy to breed bacteria, and dry hair, etc., and achieve the effects of improving environmental performance, inhibiting growth, and reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

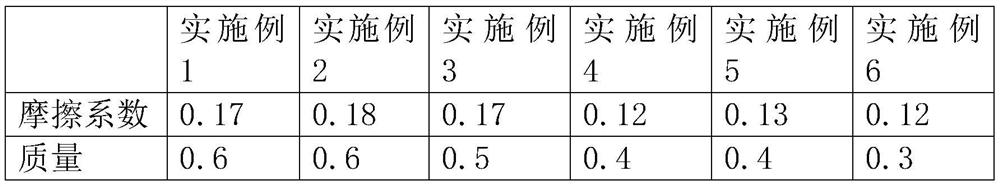

Examples

Embodiment 1

[0049] A debris nourishing shampoo, including the following components:

[0050] Water 120g; coconut oil diethanolamide 3.15 g; 22.5 g of coconut glucosine; purple oil 1.5g; sodium chloride 0.3 g; pirazonium zinc 0.3 g.

[0051] The preparation method of shampoo is as follows:

[0052] (1) Preparation of aqueous phase: In a 1L clean first stirring pan, under normal temperature conditions, stirring at a rotational speed of 1000 r / min, 120 g of water, 25.5 g of coconut glucoside, 0.3 g of sodium chloride, pyrir Sinium zinc 0.3 g, warmed to 80 ° C and stir evenly, heat the insulation for 30 min, to obtain a water phase;

[0053] (2) Preparation of oil phase: In a 1L clean second mixing pan, under normal temperature conditions, stirring at a speed of 1000 r / min, adding coconut oil diethanolamide 3.15 g, purple oil 1.5G, heating to 80 ° C Uniform and stir well, heat for 30 min, to obtain the proof;

[0054](3) Emulsification: The aqueous phase, oil phase is filtered to a 25L emulsi...

Embodiment 2

[0057] A debris nourishing shampoo, including the following components:

[0058] 140g of water; coconut diethanolamide 3.6g; 26.25 g of coconut glucoside; purple oil 1.75 g; sodium chloride 0.35 g; pirazonium zinc 0.35 g.

[0059] The preparation method of shampoo is as follows:

[0060] (1) Preparation of aqueous phase: In a 1L clean first stirring pan, under normal temperature conditions, stirring at a rotational speed of 1000 r / min, 140 g of water, 26.25 g of coconut glucoside, 0.35 g of sodium chloride, pyrir Sinium zinc 0.35 g, temperature rise to 80 ° C and stir evenly, heat insulation for 30 min, and water phase;

[0061] (2) Preparation of the oil phase: In a 1L clean second mixer pan, under normal temperature conditions, stirring at a speed of 1000 r / min, adding coconut oil dietholamide 3.6g, purple oil 1.75g, warmed to 80 ° C Uniform and stir well, heat for 30 min, to obtain the proof;

[0062] (3) Emulsification: The aqueous phase, oil phase is filtered to a 25L emu...

Embodiment 3

[0065] A debris nourishing shampoo, including the following components:

[0066] Water 160g; coconut oil diethanolamide 4.2g; coconut glucosine 30g; purple oil 2g; sodium chloride 0.4 g; pirazonium zinc 0.4 g.

[0067] The preparation method of shampoo is as follows:

[0068] (1) Preparation of aqueous phase: In a 1L clean first stirring pan, under normal temperature conditions, stirring at a temperature of 1000 r / min, 160 g of water 160g, 30 g of coconut glucosamin, 0.4 g of sodium chloride, pyridium chloride Zinc 0.4g, warmed to 80 ° C and stir evenly, heat insulation for 30 min, to obtain a water phase;

[0069] (2) Preparation of the oil phase: In a 1L clean second stirring pan, stirring at normal temperature conditions, stirring at a rotational speed of 1000 r / min, adding coconut oil diethanolamide 4.2g, purple oil 2G, temperature rise to 80 ° C and Uniform mixing, heat insulation for 30 minutes, resulting in the proof;

[0070] (3) Emulsification: The aqueous phase, oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com