High-dispersion supported PtCo nano-alloy catalyst as well as preparation method and application thereof

A technology of alloy catalysts and nano-alloys, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of chronic poisoning of toluene and complicated preparation process, and improve the structure The effects of stability, ease of preparation, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1.536gMg(NO 3 ) 2 ·6H 2 O, 1.125gAl(NO 3 ) 3 9H 2 O and 0.0173gCo(NO 3 ) 2 ·6H 2 O was prepared into 100ml mixed salt solution, and LiOH solution with a concentration of 0.1mol / L was added dropwise to the above mixed metal salt solution, and the pH of the solution was adjusted to 9.0; crystallized at a reaction temperature of 70°C for 24 hours; cooled to room temperature, deionized Centrifuge and wash with water until neutral, and dry at 70°C to obtain MgAl-Co-LDH precipitates.

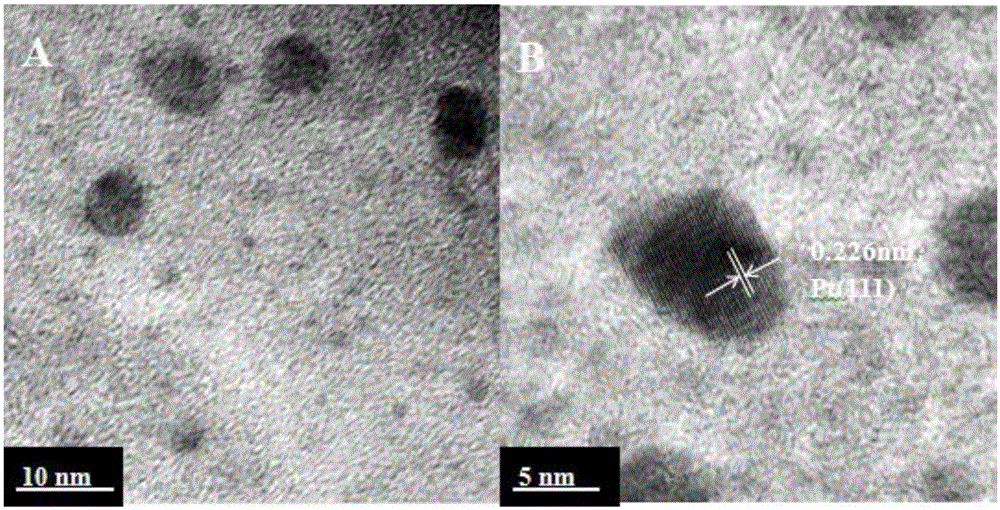

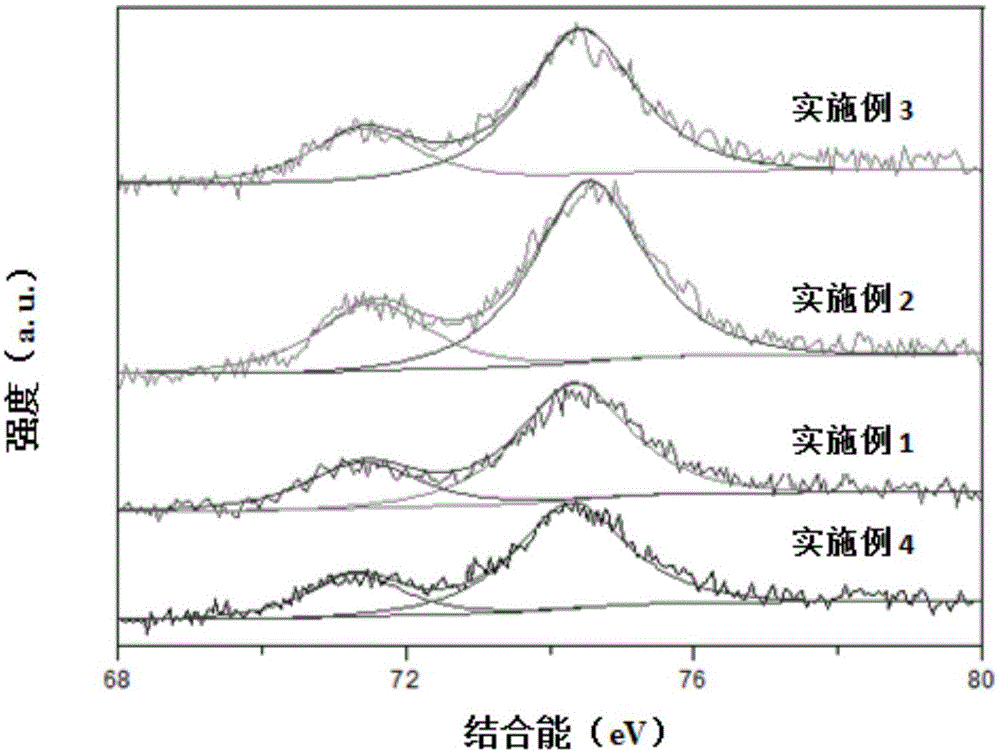

[0022] Precipitate 0.1235gMgAl-Co-LDH, 0.0883gNa 2 PtCl 4 ·6H 2 O and 1.418g of melamine were mixed, heated to 500°C under a nitrogen atmosphere, kept for 5h, and cooled to room temperature naturally to obtain a highly dispersed and supported nano-PtCo alloy catalyst. The average particle size of metal alloy nanoparticles is 5nm, the mass percentage of Pt element in the catalyst is 4.6%, and the mass percentage of Co element in the catalyst is 0.5%.

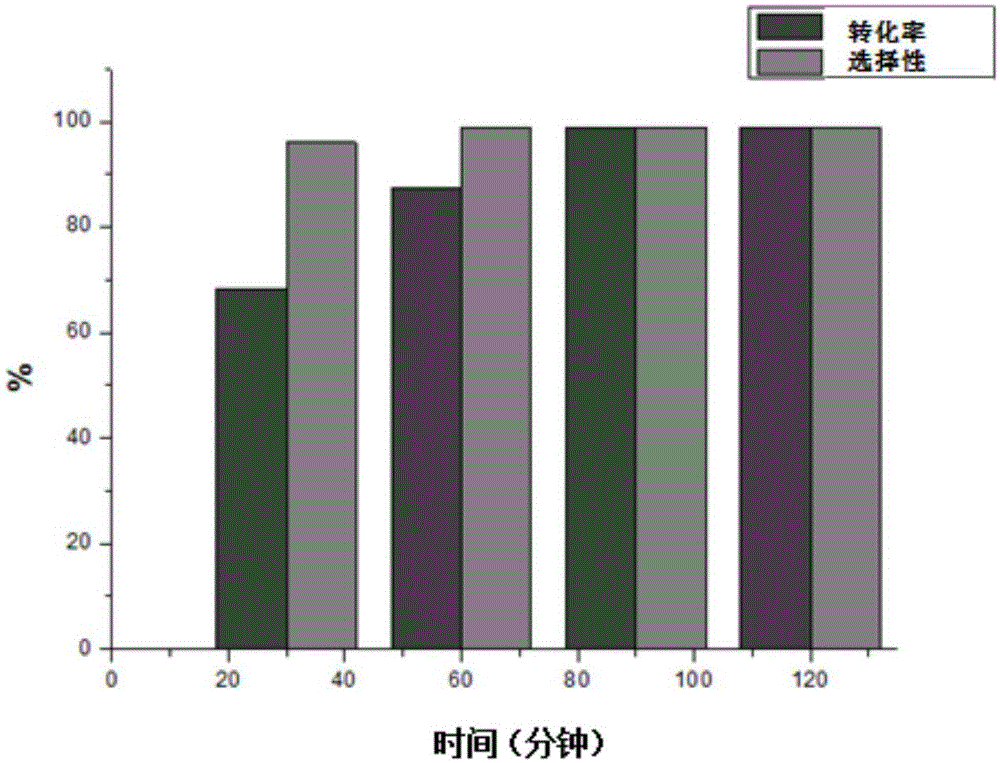

[0023]For the hydrogenation cat...

Embodiment 2

[0025] 1.536gMg(NO 3 ) 2 ·6H 2 O, 1.125gAl(NO 3 ) 3 9H 2 O and 0.04325gCo(NO 3 ) 2 ·6H 2 O was prepared into 100ml mixed salt solution, and LiOH solution with a concentration of 0.1mol / L was added dropwise to the above mixed metal salt solution, and the pH of the solution was adjusted to 9.0; crystallized at a reaction temperature of 70°C for 24 hours; cooled to room temperature, deionized Centrifuge and wash with water until neutral, and dry at 70°C to obtain LDHs precipitates. 0.1235gMgAl-Co-LDH, 0.0893gNa 2 PtCl 4 ·6H 2 O and 1.418g of melamine were mixed, heated to 600°C under a nitrogen atmosphere, kept for 5h, and naturally cooled to room temperature to obtain a highly dispersed and supported nano-PtCo alloy catalyst. The average particle size of the alloy is 7nm, the mass percentage of Pt in the catalyst is 4.7%, and the mass percentage of Co in the catalyst is 1.0%.

[0026] The test method for the catalytic reaction performance of cinnamaldehyde hydrogenat...

Embodiment 3

[0028] 1.536gMg(NO 3 ) 2 ·6H 2 O, 1.125gAl(NO 3 ) 3 9H 2 O and 0.1068gCo(NO 3 ) 2 ·6H 2 O was prepared into 100ml mixed salt solution, and LiOH solution with a concentration of 0.1mol / L was added dropwise to the above mixed metal salt solution, and the pH of the solution was adjusted to 9.0; crystallized at a reaction temperature of 70°C for 24 hours; cooled to room temperature, deionized Centrifuge and wash with water until neutral, and dry at 70°C to obtain MgAl-Co-LDH precipitates. 0.1235gMgAl-Co-LDH, 0.0907ga 2 PtCl 4 ·6H 2 O and three 1.418g polycyanamides were mixed, heated to 600°C under a nitrogen atmosphere, kept for 6h, and naturally cooled to room temperature to obtain a highly dispersed and supported nano-PtCo alloy catalyst. The average particle size of metal alloy nanoparticles is 9.5nm, the mass percentage of Pt element in the catalyst is 5.0%, and the mass percentage of Co element in the catalyst is 1.5%.

[0029] The test method for the catalytic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com