Preparation process of silicone sealant base stock

A technology for preparation process and base material, applied in the direction of adhesives, etc., can solve the problems of large fluctuation in the quality of base material, the appearance of base material is not delicate, and the process time is long. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

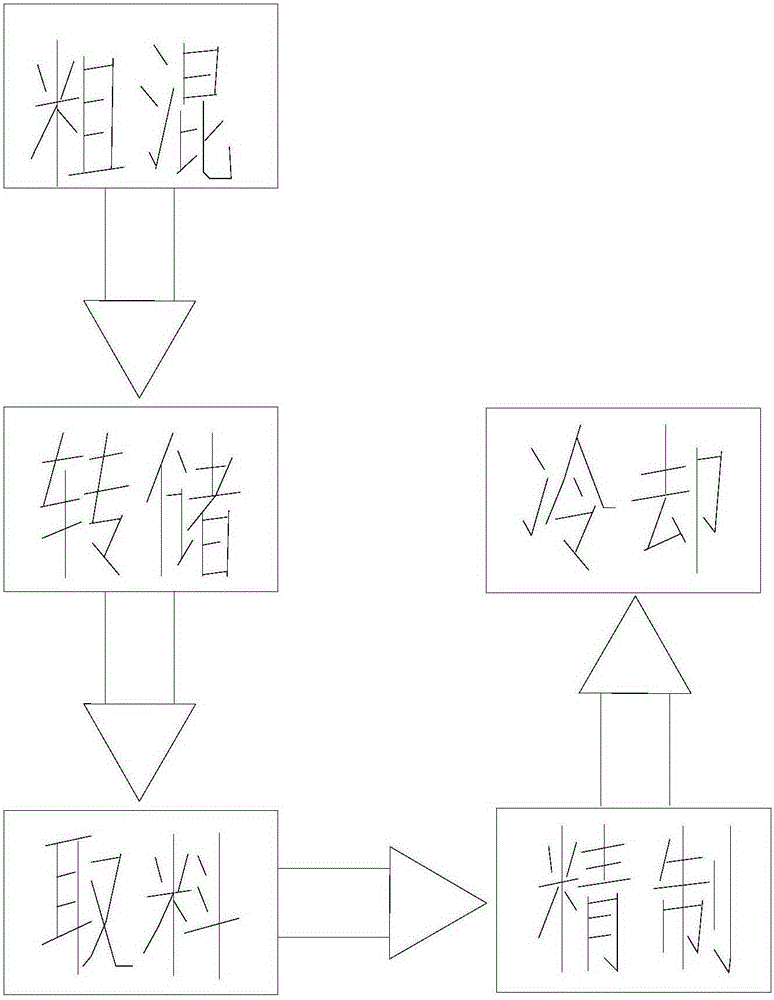

[0016] refer to figure 1 , the production preparation technology of a kind of silicone sealant base material of the present invention, comprises the steps:

[0017] A Rough mixing: Put the materials used for preparing the base material into a vacuum kneader, and use the vacuum kneader to roughly mix the materials to make a rough mix base material;

[0018] B dumping: put the coarse mixed base material into the transfer storage tank through the gear pump for storage and backup;

[0019] C taking material: use the gear pump to drive the rough mixed base material in the transfer storage tank into the twin-screw extruder;

[0020] D Refining: In the twin-screw extruder, the rough mixed base material is refined and dehydrated and defoamed through the twin-screw;

[0021] E cooling: the refined base material is cooled through a cooler to obtain a high-quality base material;

[0022] The materials in the rough mixing step A need to be screened and put into a vacuum kneader for rou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap