Super-warm clothing material

A kind of clothing, super technology, applied in the direction of clothing, clothing, protective clothing, etc., can solve the problems of poor moisture conductivity, synthetic film airtight, non-moisture conductivity, etc., to achieve good thermal insulation performance and good moisture dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

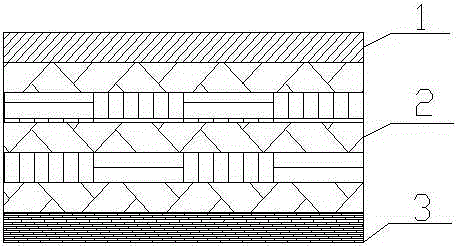

[0015] Such as figure 1 Shown is a schematic structural view of the super warm clothing material of the present invention. A super warm clothing material is composed of three layers: the surface layer, the middle layer and the inner layer. The surface layer and the inner layer are respectively compounded on the upper and lower end faces of the middle layer. The surface layer is The protective layer 1, the middle layer are the insulation layer 2 and the inner layer is the comfort layer 3, and the fabric of the protective layer 1 is a PTFE waterproof and moisture-permeable fabric, which realizes the effects of windproof, waterproof and moisture-permeable.

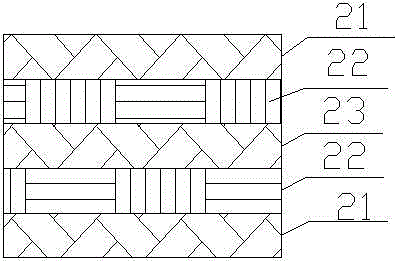

[0016] Such as figure 2 Shown is the structural representation of insulation layer 2 of the present invention, and the lining of insulation layer 2 is polyimide fabric 21, goose down filler 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com