Device and method for repairing underground water through process of activating sodium persulfate by using Fe (II)

A sodium persulfate and groundwater technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve problems such as refractory biodegradation, water environment and biological threats, and achieve simple materials and no defects Effects of environmental impact and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

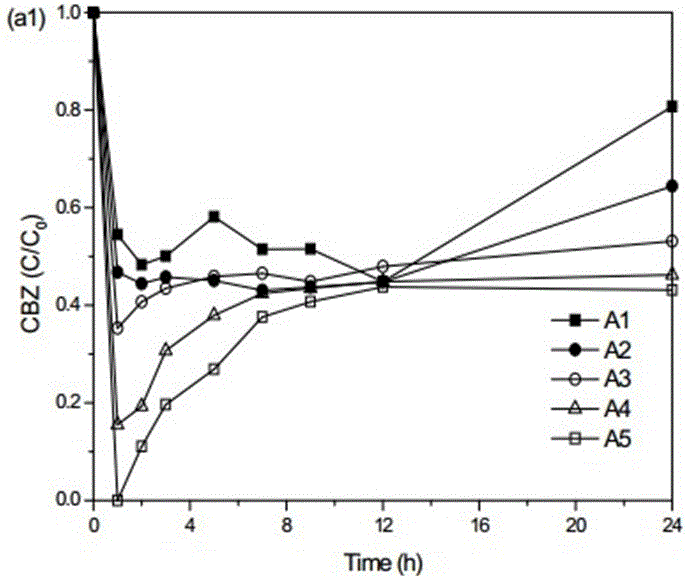

Embodiment 1

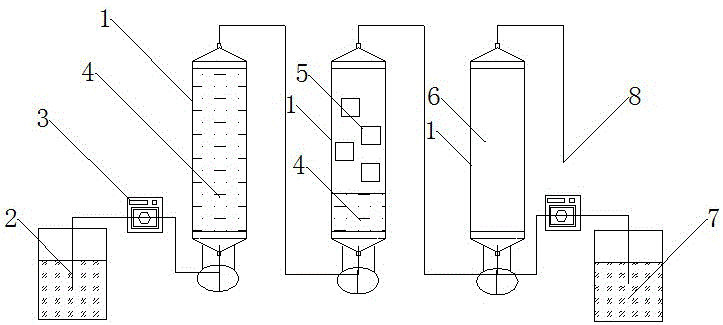

[0028] As shown in Figure 1, the device consists of three parts of reaction vessel column to form a semi-continuous in-out reaction device. The bottom of the column of the first part of the reaction vessel is connected to a closed container containing a 0.01-0.1mM simulated pollutant carbamazepine (CBZ) solution, and the upper end is connected to the lower end of the column of the second part of the reaction vessel, and a slow-release material is placed in it, and The release of SPS begins upon contact of the solution. The upper end of the column of the second part of the reaction vessel is connected to the bottom of the column of the third part of the reaction vessel, and the bottom of the column of the third part of the reaction vessel is connected to a freshly prepared Fe 2+ The closed container of the solution, by controlling the peristaltic pump, different flow rates of Fe 2+ The solution is input to the column of the third part of the reaction vessel, the upper end of w...

Embodiment 2

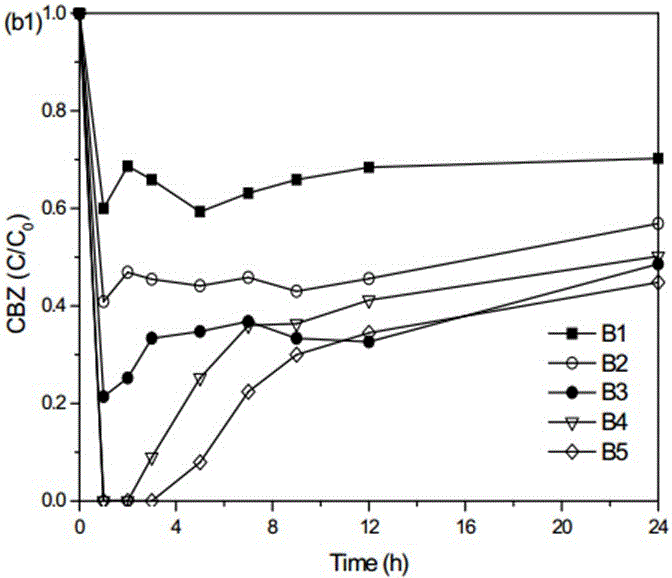

[0034] Using the device described in Example 1, the slow-release material B releases SPS covered by Fe 2+ The degradation effect on CBZ after activation simulates the ISCO repair technology. Material B paraffin: quartz sand: SPS is 10:1:4. Anyway, the conditions are shown in Table 2. The concentration of pollutants (CBZ) is 0.02mMol / L, and the reaction time is 24h. Fe 2+ The concentration is controlled at 50mg / L. Sodium citrate is 10mg / L.

[0035] label B1 B2 B3 B4 B5 Quantity (block) 1 1 1 2 2 Flow rate (mL / min) 8 8 4 8 4 Sodium citrate none have have have have

[0036] It can be seen from Figure 3 that it reflects the degradation of continuous CBZ in the device by paraffin slow-release materials under different conditions. Similar to the degradation trend of cement slow-release materials, when double slow-release materials are added, and the input flow rate of CBZ and Fe2+ solution is reduced, the CBZ in the solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com