Fluorescent glass ceramic, preparation method of fluorescent glass ceramic and application of fluorescent glass ceramic in preparing laser light source

A fluorescent glass, laser light source technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor heat dissipation performance of high-power light source packaging, achieve the effect of not affecting luminous performance, solving material deterioration, and improving luminous power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

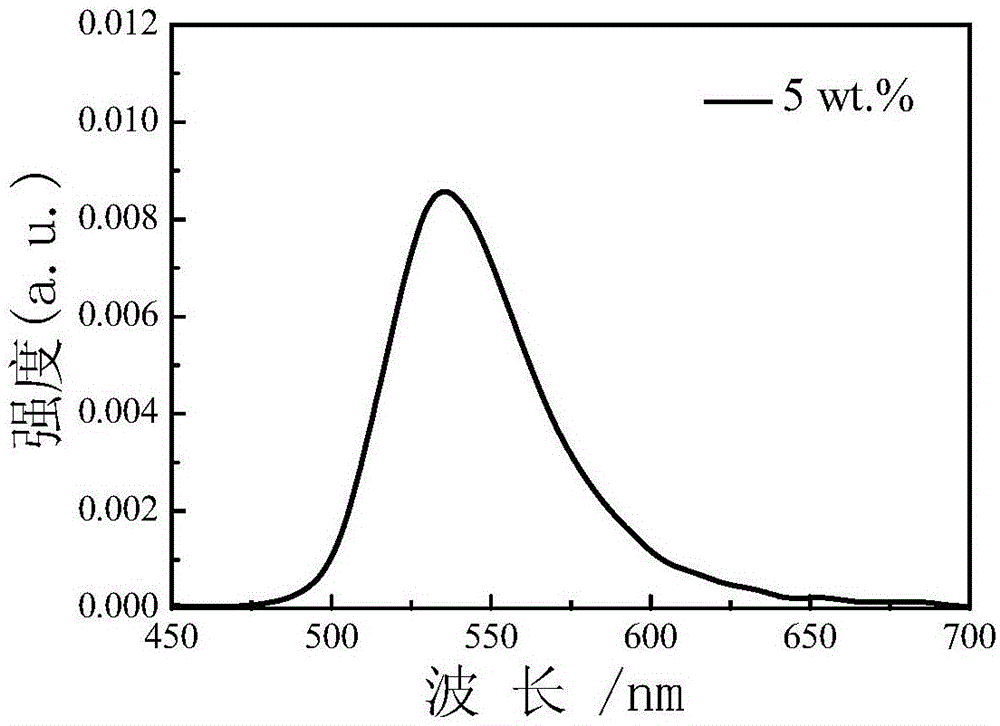

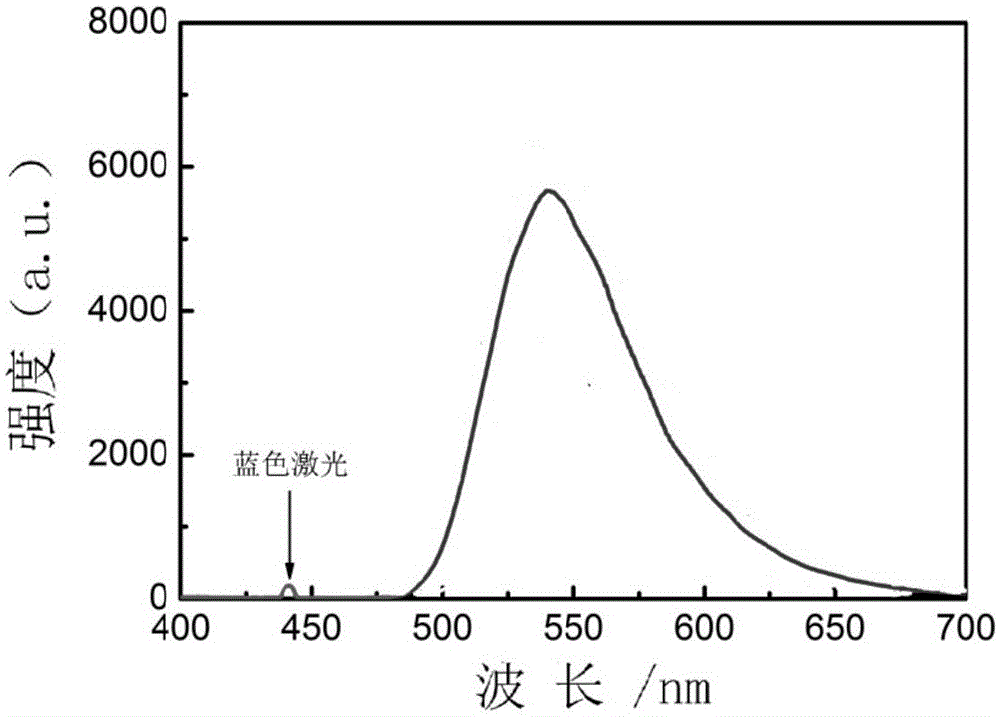

[0031] A fluorescent glass-ceramic made of 95wt% SiO 2 -BaO-ZnO-B 2 o 3 -Al 2 o 3 Low melting point glass powder with 5wt% Si 5.5 al 0.5 o 0.5 N 7.5 :Eu 2+ Composition of green fluorescent powder.

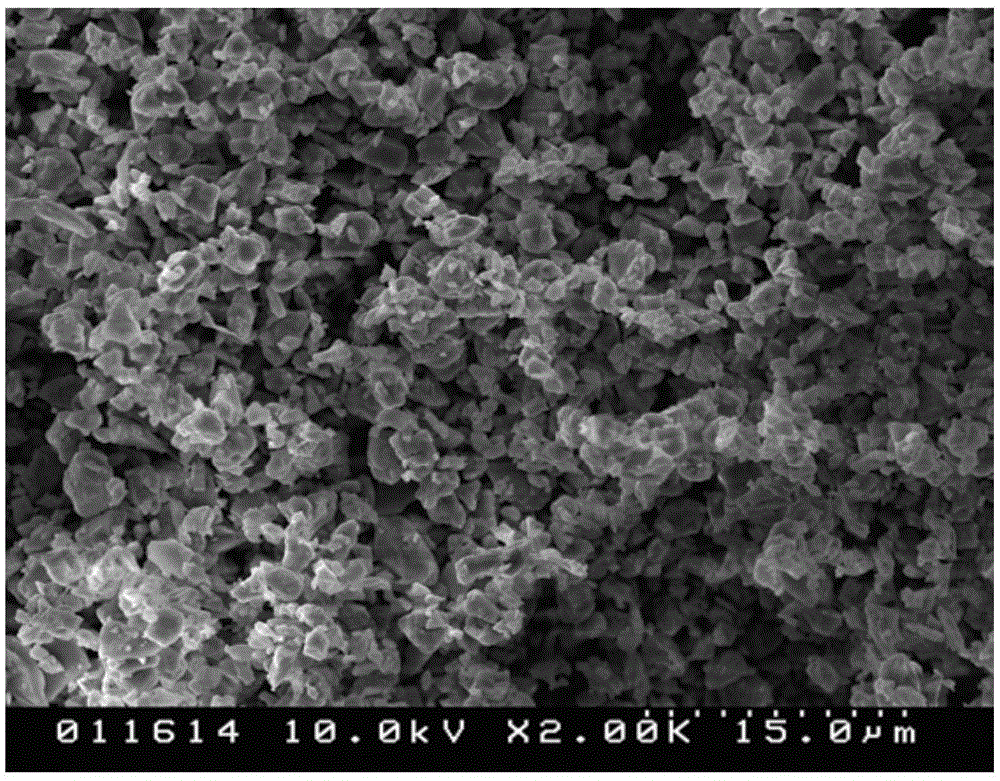

[0032] 1) Accurately weigh α-Si according to the proportion 3 N 4 ,AlN,Al 2 o 3 and Eu 2 o 3 The raw materials are put into a crucible after being mixed evenly, and moved to a high-temperature carbon tube furnace filled with nitrogen reducing gas, and the pressure in the furnace is 1.0Mpa. After the temperature is raised to 2000°C, the holding time is set to 3h. After the temperature in the furnace is cooled to room temperature 25°C, the sample is taken out for grinding and sieving to obtain high-purity Si 5.5 al 0.5 o 0.5 N 7.5 :Eu 2+ Green phosphor.

[0033] 2) Accurately weigh 40% SiO according to the molar ratio 2 , 30% BaO, 20% ZnO, 5% B 2 o 3 , 5% Al 2 o 3 After mixing evenly in an agate mortar, move it into a crucible, place it in a high-temperature ...

Embodiment 2

[0039] A fluorescent glass-ceramic made of 95wt% CaO-MgO-SiO 2 Glass powder with 5wt% Si 5.5 al 0.5 o 0.5 N 7.5 :Eu 2+ Composition of green fluorescent powder.

[0040] 1) Accurately weigh α-Si according to the proportion 3 N 4 ,AlN,Al 2 o 3 and Eu 2 o 3 The raw materials are put into a crucible after being mixed evenly, and moved to a high-temperature carbon tube furnace filled with nitrogen reducing gas, and the pressure in the furnace is 1.0Mpa. After the temperature is raised to 2000°C, the holding time is set to 3h. After the temperature in the furnace is cooled to room temperature 25°C, the sample is taken out for grinding and sieving to obtain high-purity Si 5.5 al 0.5 o 0.5 N 7.5 :Eu 2+ Green phosphor.

[0041] 2) Accurately weigh 30% CaO, 30% MgO, 40% SiO according to the molar ratio 2 After mixing evenly in an agate mortar, move it into a crucible, place it in a high-temperature carbon tube furnace filled with nitrogen reducing gas, raise the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com