Technology for fermenting halostachys caspica metallothionein and application of halostachys caspica metallothionein

A technology of metallothionein and fermentation process, which is applied in the fermentation process of salt ear wood metallothionein and its application, and in the field of biological fermentation, can solve the problems of high cost and low output, and achieve the effect of increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one: a kind of fermenting process of the metallothionein of Saltwood

[0030] A kind of fermenting technology of salt ear wood metallothionein, concrete fermentation process step is as follows:

[0031] (1) Configuration and sterilization of medium

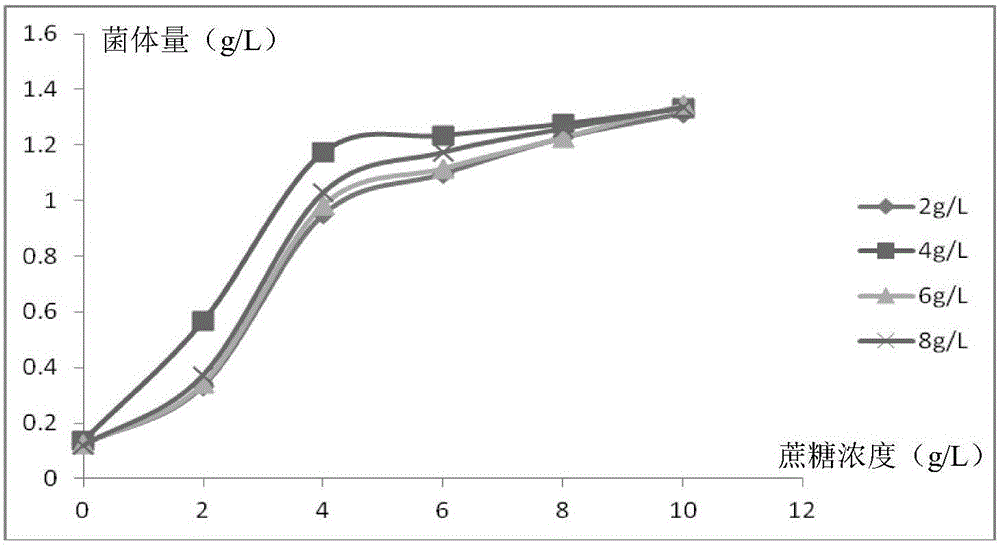

[0032]The improved fermentation medium has been obtained through condition optimization, and its composition includes two parts by weight: one part is 900mL medium containing 4g sucrose, 24g yeast extract powder, and 8g peptone; the other part is 100mL phosphate buffer containing 2.31gKH 2 PO 4 , 12.54gK 2 HPO 4 ·3H 2 O, the two parts were autoclaved separately and mixed to prepare 1 L of modified medium.

[0033] (2) Expanded culture in fermenter

[0034] Cultivate the recombinant expression transformant obtained in the prior invention at 37°C overnight, then inoculate the improved fermentation medium at a ratio of 2%, and ferment in a fully automatic fermenter with a liquid filling coefficient of 0.5, an...

Embodiment 2

[0035] Embodiment two: the selection of culture medium in the fermentation technology of salt ear wood metallothionein

[0036] The initial fermentation medium that adopts is TB medium, and initial fermentation condition is: inoculum size 1% (V / V), liquid filling volume 30 / 250mL, temperature 37 ℃, rotating speed 200r / min shaker cultivation to OD 600 When ≈0.6, add IPTG with a final concentration of 1mmol / L, and induce culture for 6h.

[0037] (1) Selection of seed age

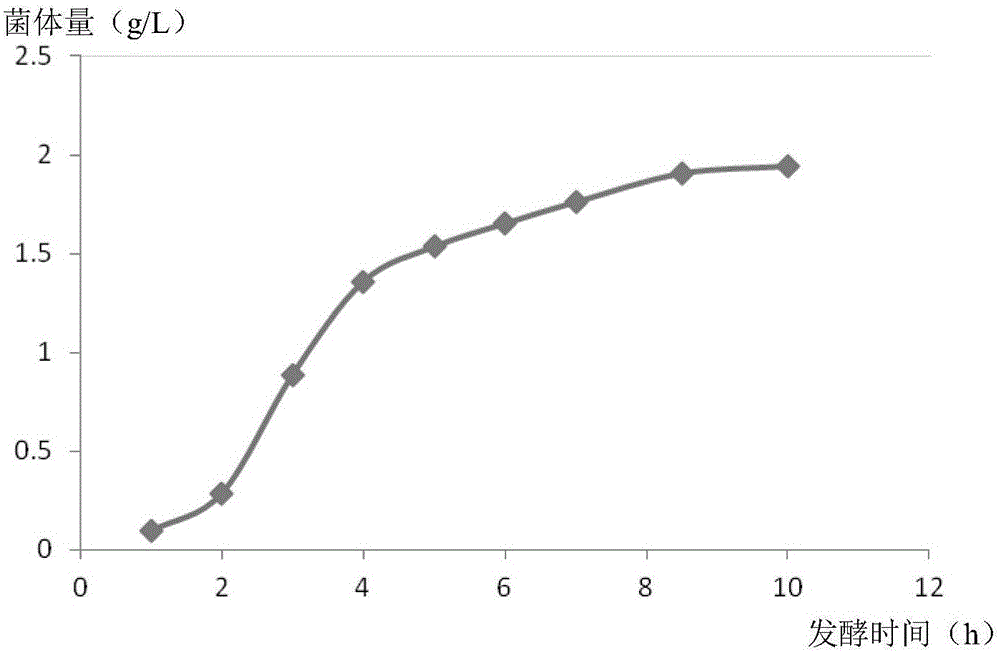

[0038] Select the most commonly used LB medium for recombinant Escherichia coli as the seed medium, and measure the growth curve of the seed liquid, see the attached figure 1 .

[0039] attached by figure 1 It can be seen that the strains are in the lag phase within 0-1h, quickly enter the logarithmic growth phase after 1h, and are in the stable phase after 6-10h, and the bacteria begin to decline after 10h. The seed age of the fermented strains should be in the middle and late logarithmic growth period. ...

Embodiment 3

[0059] Example 3: Induced expression of recombinant protein

[0060] IPTG was used as an inducer to verify the expression of metallothionein. Inoculate positive single clones in 5 mL of LB medium containing 50 mg / LAmp, culture overnight at 37°C and 220 r / min, transfer to 50 mL of LB (containing Amp) fresh medium at a volume ratio of 1:100, and continue culturing under the same conditions. OD 600 When it reaches 0.4-0.6, add isopropyl-β-D-thiogalactoside (IPTG) to a final concentration of 1mmol / L, induce expression for 4 hours, collect 2mL of bacterial liquid and centrifuge, and resuspend the pellet with 100μl 1xSDS loading buffer , boiled for 15min, 15% SDS-PAGE electrophoresis to analyze the expression results, the experimental results are attached Figure 8 .

[0061] attached by Figure 8 It can be seen that the expression of metallothionein can be induced by different monoclones, so the monoclonal used is an inducible and correct recombinant bacteria, and the expressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com