A magnetic source beacon for downhole drilling positioning

A magnetic source and beacon technology, applied in construction and other directions, can solve the problems that the geometric guidance positioning technology cannot meet the high-precision requirements of the wellbore trajectory, does not consider the target target's ability to guide the drilling wellbore, and cannot meet the high-precision guidance, etc., to achieve Improve the applicability of the system, improve the accuracy of measurement and calculation, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

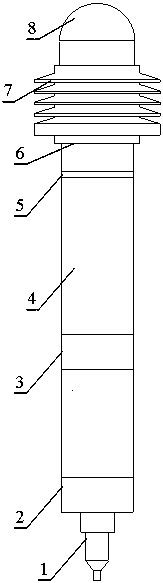

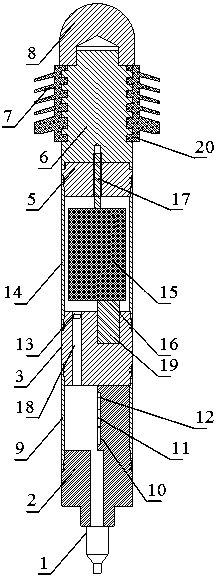

[0018] Embodiment 1, a magnetic source beacon for downhole drilling and positioning mentioned in the present invention, including a cable joint 1, an instrument cabin 2, a power supply connection sub-section 3, an alternating magnetic field signal generation sub-section 4, a guide connection sub-section 5, Hydraulic plug seat 6, hydraulic plug 7, metal guide head 8, the lower part of the instrument cabin 2 is connected to the cable joint 1, and the upper part of the instrument cabin 2 is connected to the power supply connection nipple 3, the alternating magnetic field signal generating nipple 4, and the guide connecting nipple Section 5, the guide piece is connected to the upper part of the short joint 5 to connect the hydraulic plug seat 6, the hydraulic plug seat 6 is fixed with the hydraulic plug plug 20, and the hydraulic plug 7 is connected to the metal guide head 8.

[0019] Wherein, three slot holes are arranged in the instrument cabin 2, and the signal processing circui...

Embodiment 2

[0025] Embodiment 2: A magnetic source beacon for downhole drilling and positioning, mainly composed of a cable joint 1, an instrument cabin 2, a power supply connection sub-section 3, an alternating magnetic field signal generation sub-section 4, a guide connection sub-section 5, and a hydraulic plug seat 6 , a hydraulic plug 7 and a metal guide head 8;

[0026] Such as figure 2As shown, the cable joint 1 is connected with the lower cable to provide the excitation current and the upload channel for the inclinometer data for the magnetic source beacon. The instrument cabin 2 is made of non-magnetic materials such as aluminum alloy and austenitic stainless steel. The signal processing circuit 10, the triaxial accelerometer 11 and the steady current drive circuit 12 are placed in the three slots respectively, the triaxial accelerometer 11 measures the triaxial gravity field data, the inclinometer data obtained by the signal processing circuit 10 is uploaded to the ground throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com