A super -damaged vibrator with negative rigidity with an inclined magnet

A technology of super damping and vibration isolator, applied in the direction of shock absorber, shock absorber-spring combination, shock absorber, etc. The effect of widening the vibration isolation frequency band, suppressing the vibration response, and facilitating adjustment and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

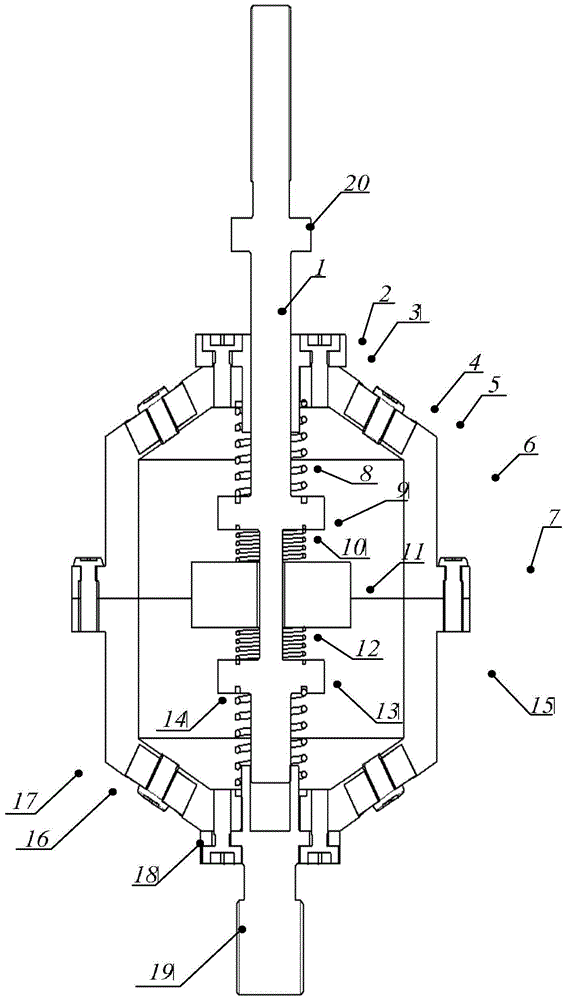

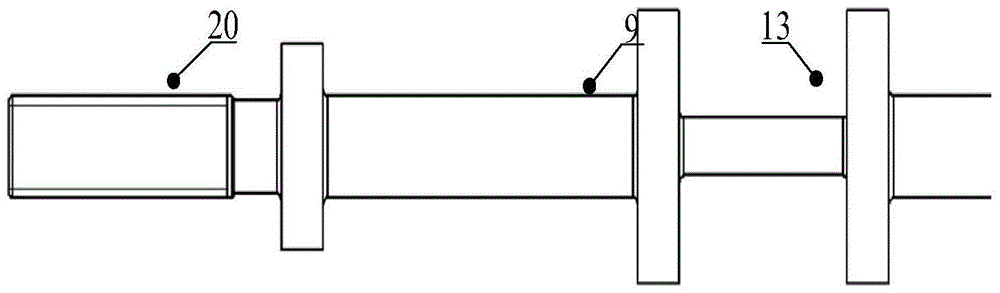

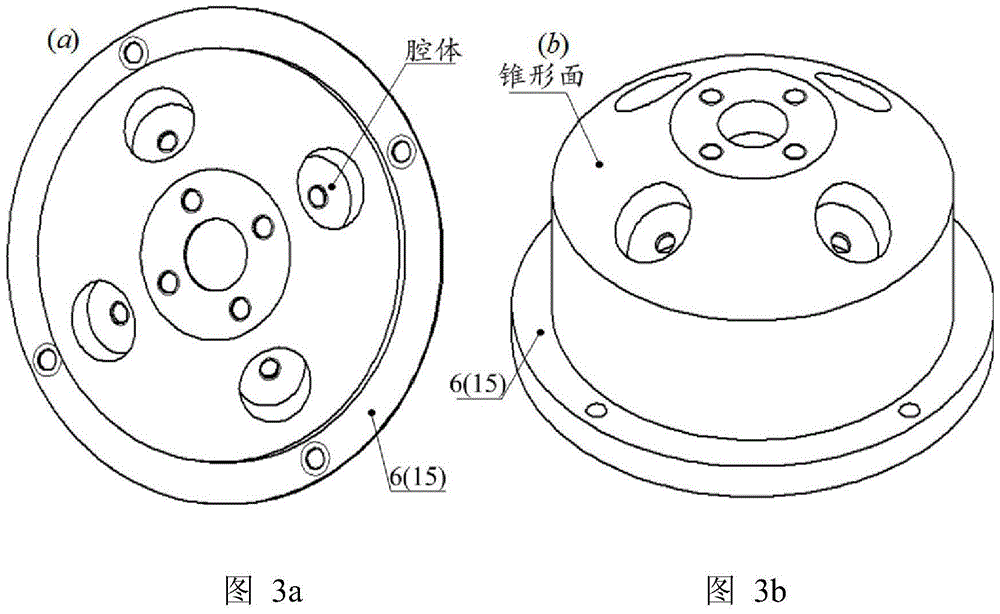

[0026] Such as figure 1 , figure 2 , shown in Fig. 3 and Fig. 4, the present invention is a kind of super-damping vibration isolator that adopts inclined magnet to produce negative stiffness, comprises the central shaft with first boss 20, second boss 9, third boss 13 1. A threaded segment is provided on the upper shaft section of the first boss 20; a sliding bearing 3 is arranged axially between the first boss 20 and the second boss 9; the sliding bearing 3 passes through The first fastening bolt 2 is fastened to the upper end surface of the upper end cover 6; four cavities are arranged on the conical surface of the upper end cover 6; the first inclined annular permanent magnet 5 is installed on the upper end cover 6 in the cavity on the conical surface; the upper end cover 6 and the first inclined annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com