Double-temperature-zone baking device for split type dewar exhaust and realization method thereof

A baking device and dual temperature zone technology, which is applied in the field of packaging of infrared detector Dewar components, can solve the problems of shortening the exhaust time of Dewar ultra-high vacuum and insufficient exhaust effect, and achieve simple structure and low price , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

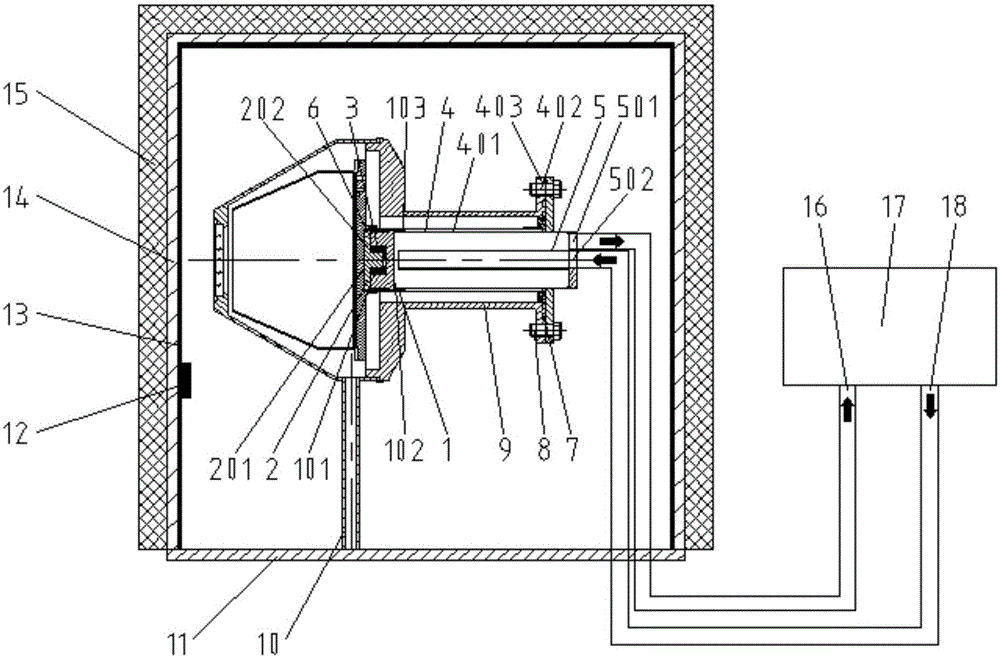

[0073] The specific implementation of this patent will be further described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, its main implementation method is as follows:

[0074] 1. The preparation method of each part in this patent:

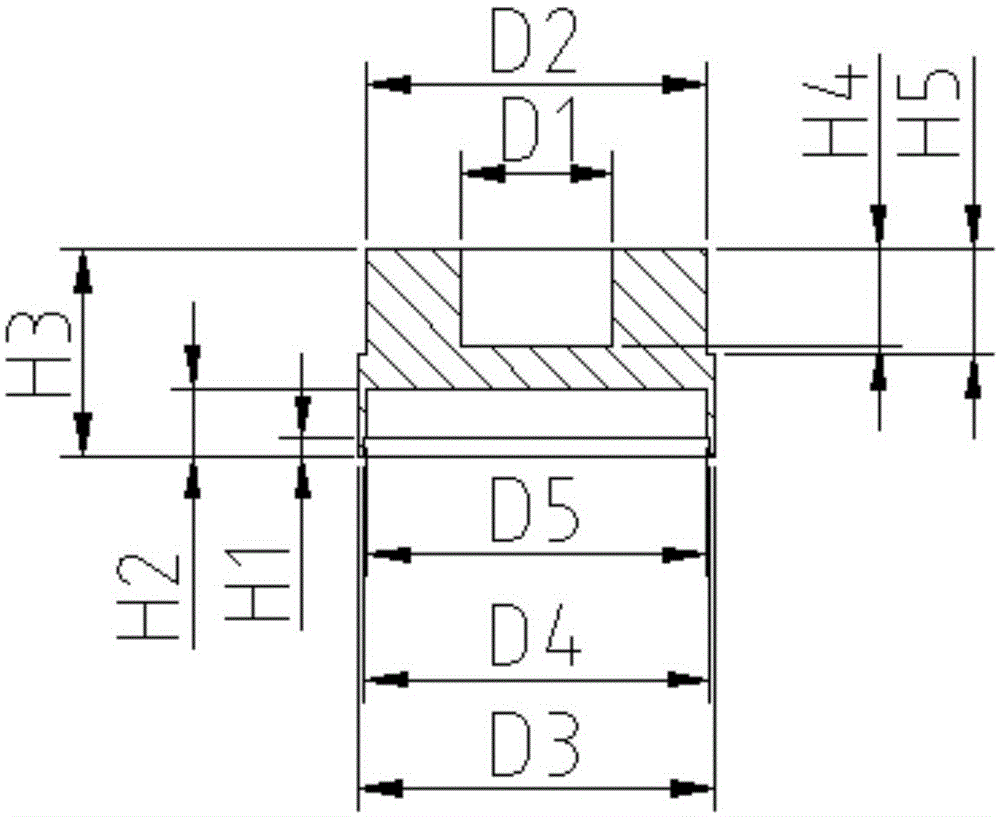

[0075] 1) if figure 2 As shown, the cold chain seat 1 is made of oxygen-free copper material, which is a cylindrical part, and the inner and outer surfaces are polished. After polishing, it is cleaned in an ultrasonic cleaner with acetone, alcohol and deionized water for 5-10 minutes to remove the residues in the process. Grease and debris on part surfaces; see figure 2 , where D1=9mm, D2=20mm, upper tolerance is -0.06mm, lower tolerance is -0.02mm, D3=21mm, D4=20.4mm, D5=20mm, upper tolerance is +0.06mm, lower tolerance is +0.02mm ;H1=1mm, H2=4mm, H3=12.2mm, H4=5.7mm, H5=6.2mm;

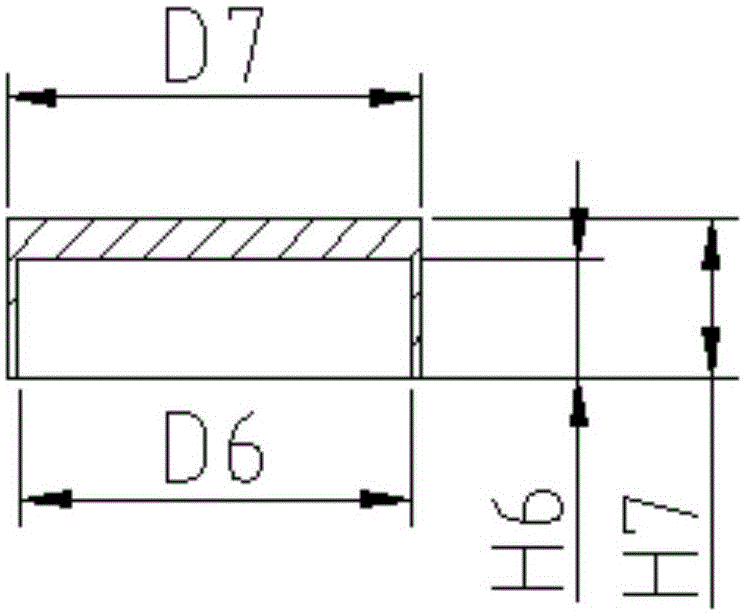

[0076] 2) if image 3 As shown, the cold cap 2 is made of oxygen-free copper material, which is a cylindrical part, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com