Rapid-heating heat treatment furnace

A heat treatment furnace and fast technology, applied in the field of heat treatment, can solve the problems of high use cost, temperature overshoot, applicability limitation, etc., and achieve the effects of high temperature and time control accuracy, fast heating and cooling speed, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

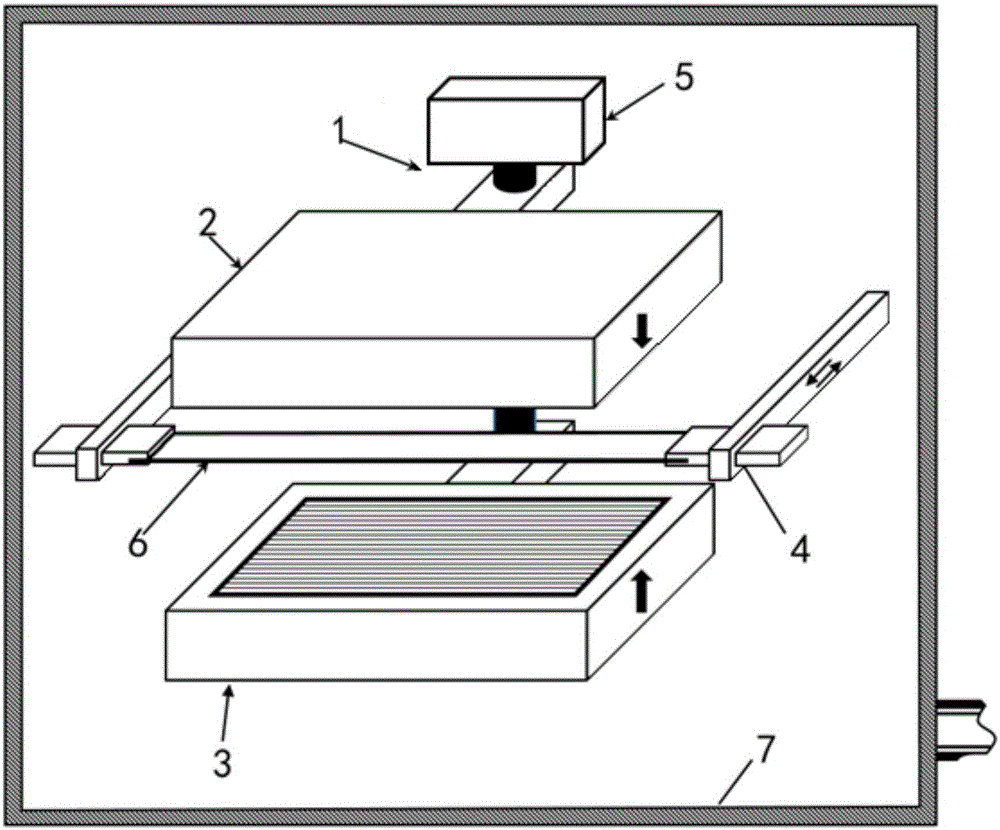

[0031] Such as figure 1 with 2 As shown, the heat treatment furnace for rapid temperature rise in this embodiment includes: a furnace cavity 7, an upper heating plate 2 and a lower heating plate 3 arranged oppositely in the furnace cavity 7 for opening and closing the upper heating plate 2 and the lower heating plate 3 The rapid lifting mechanism 1 is used to install the sample rack 4 of the sample, and the sample rack 4 can be stretched, and is used to drive the sample into and out of the radiation area between the upper heating plate 2 and the lower heating plate 3 .

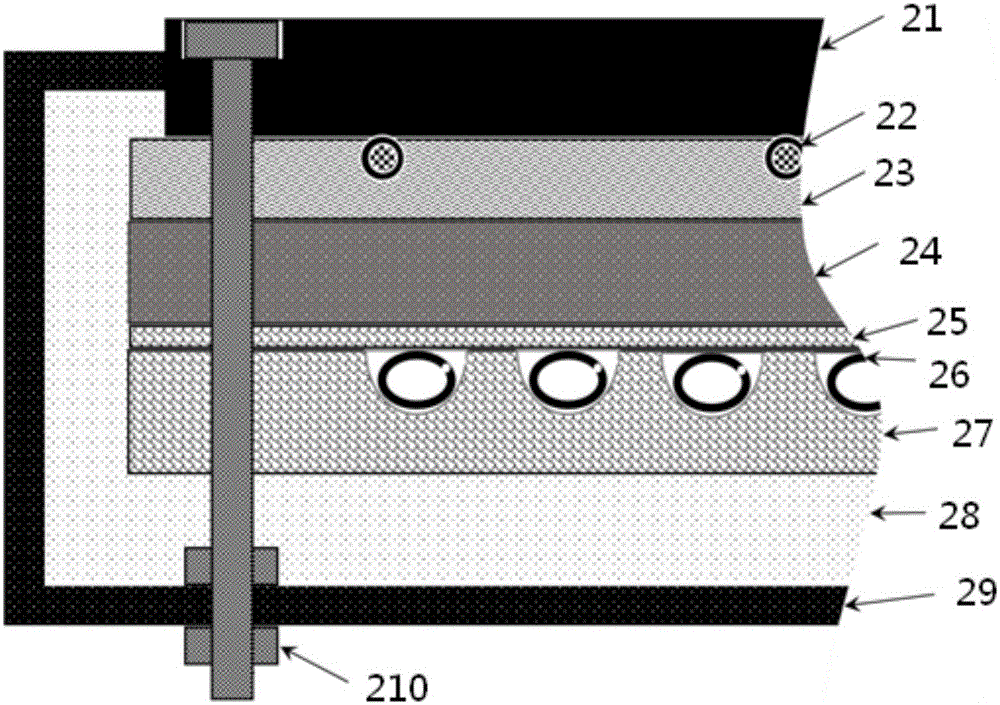

[0032]The upper and lower heating plates use a multi-layer composite structure to make the temperature of the heating surface uniform. The heat in the heating plate is provided by heating wires 26. There are multiple groups of heating wires 26. The number and distribution method can be set according to needs. This embodiment is installed in an evenly distributed manner. The heating wire 26 adjusts the power a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com