Microbubble performance test and assessment experimental platform and test and assessment method thereof

A technology of an experimental platform and an evaluation method, applied in the microbubble performance test and evaluation experimental platform and its field of test evaluation, can solve the problems of inability to quantify the particle size distribution of microbubbles, single use and function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

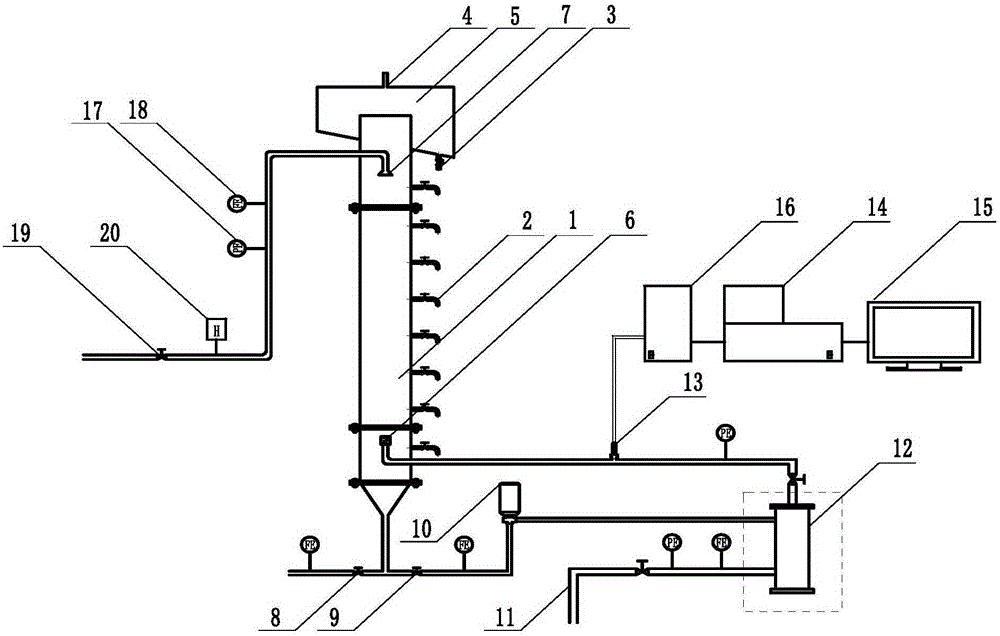

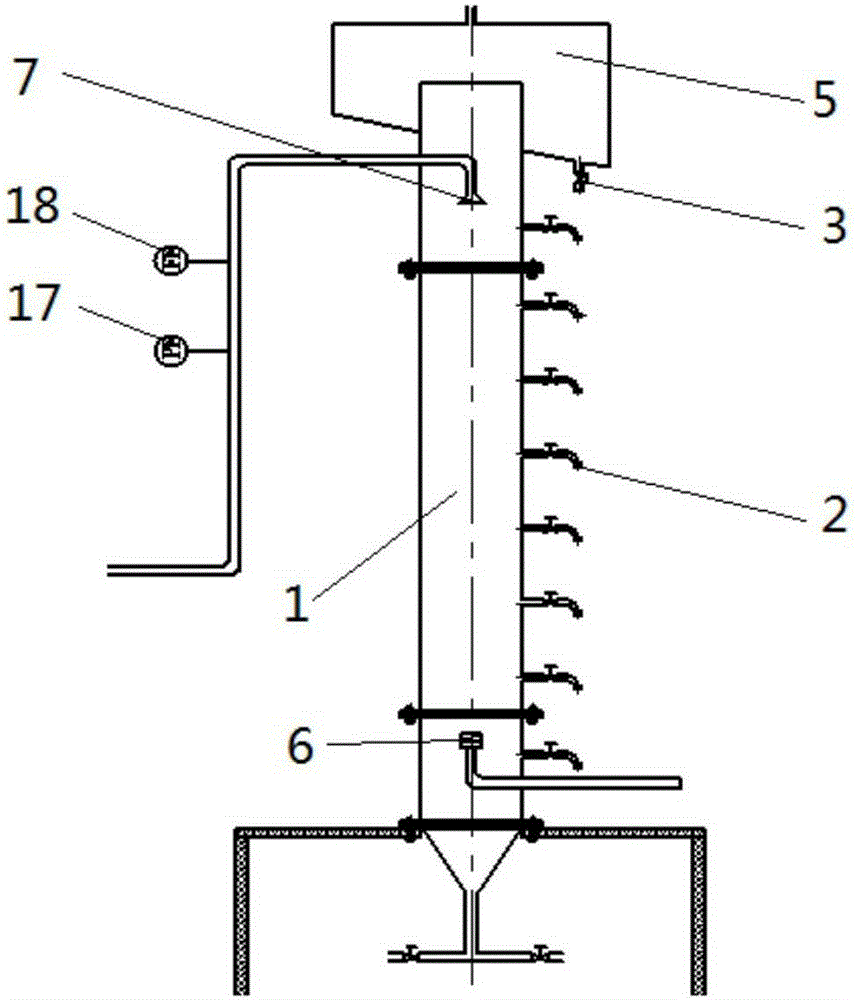

Embodiment 1

[0037] A microbubble performance test evaluation experimental platform, consisting of air flotation column 1, external drainage flow regulating gate valve 8, backflow gate valve 9, centrifugal pump 10, micro bubble generating device 12, laser particle size analyzer 14, computer 15, and sample addition controller 16. , Pressure gauge 17, flow meter 18, gas inlet 11, dosing metering pump 20 and other components. A scum collection tank 5 is provided on the top of the air flotation column 1, and a return water distribution unit 6 and a raw water distribution unit 7 are provided on the side wall of the air flotation column 1. The return water distribution unit 6 is located at the bottom of the air flotation column 1, and microbubbles are generated. The microbubbles and water-gas-liquid mixture produced by the device 12 are injected into the lower axial cross section of the air float column 1 through the reflux water distribution unit 6. The microbubble particle size test sampling po...

Embodiment 2

[0040] For a method for testing and evaluating microbubble performance, see Example 1. When testing and evaluating the microbubble performance test and evaluation experimental platform, first close the external drainage flow regulating gate valve 8 and the return gate valve 9 at the bottom of the air flotation column 1, and inject tap water into the air flotation column 1 through the raw water distribution unit 7 on the top of the air flotation column 1 When the liquid level in the air flotation column 1 reaches a certain height, specific gas air, nitrogen or natural gas is injected into the microbubble generating device 12 through the gas inlet 11, and then the return gate valve 9 is opened and the centrifugal pump 10 is turned on. The gas-liquid mixture with water is injected into the lower axial cross section of the air float column 1 through the reflux water distribution unit 6. After a period of time, the whole process can be in a stable equilibrium state. The gas-liquid ...

Embodiment 3

[0045] For a method for testing and evaluating microbubble performance, see Example 1. When the microbubble performance test evaluation experimental platform is used for test evaluation, the difference from Embodiment 2 is that the microbubble generating device 12 uses a tubular microbubble generator. The micro-bubble generator adopts the structure of "air distribution in the outer cavity-water in the inner cavity". Water enters the micro-bubble generator tangentially to form a swirling flow outside the microporous tube, and shear the airflow to generate microbubbles. In this example, not only the direct online test evaluation of the average particle size of the generated microbubbles was performed, but also the test evaluation of the oily sewage air flotation and degreasing effect was performed. The test of the average particle size of the microbubbles was the same as in Example 2. In order to test the degreasing effect of air flotation, samples were taken from the sampling po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com