Coaxial photoelectric composite low voltage cable

A photoelectric composite and low-voltage cable technology, which is applied in the direction of coaxial cable/analog cable, insulated cable, communication cable, etc., can solve the problems that the cable cannot bear the tension and the outer diameter of the cable is large, and achieves low network construction costs and avoids secondary Wiring, the effect of superior tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

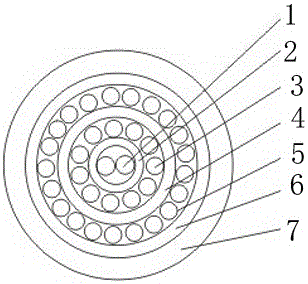

[0015] Such as figure 1 A coaxial photoelectric composite low-voltage cable is shown, a group of optical fiber units 1 are used as the central layer, and the first insulating layer 2 is extruded on the outer layer of the optical fiber unit 1, and the outer layer of the first insulating layer 2 is loosely wound. The first conductor layer 3 is applied in a manner, and then the second insulating layer 4 is extruded on the outside of the first conductor layer 3, and the second conductor layer 5 is applied on the outside of the second insulating layer 4 in a sparsely wound manner, and then the second A third insulation layer 6 is extruded on the outside of the conductor layer, and then a layer of outer sheath 7 is extruded on the outside of the third insulation layer 6 .

[0016] In order to improve the performance of the cable again, the cross-sectional ratio of the first insulating layer 2, the second insulating layer 4 and the third insulating layer 6 is 1:2:4; The cross sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com