GaN-base LED chip preparation method capable of achieving high-efficient packaging

An LED chip, high-efficiency technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of low production efficiency, high defect rate, poor reliability, etc., to achieve low cost, stable and reliable product performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

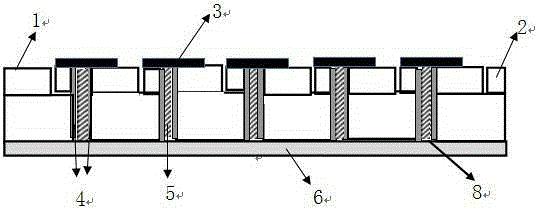

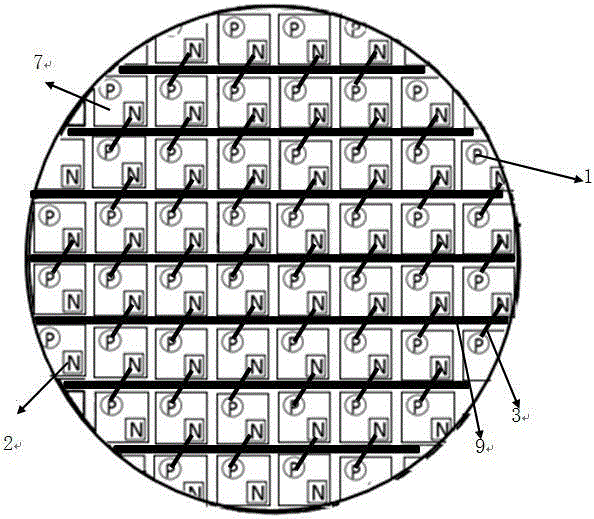

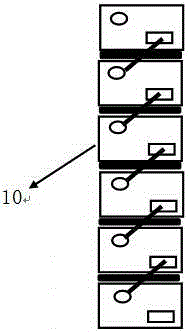

[0025] The method for preparing a GaN-based LED chip that can realize high-efficiency packaging of the present invention includes the following steps:

[0026] (1) Preparation of epitaxial wafers

[0027] Such as figure 1 As shown, an epitaxial layer is grown on the substrate 6 to form an epitaxial wafer; the epitaxial layer is sequentially composed of a GaN layer, an N-type GaN layer, a quantum well active region, and a P-type GaN layer from bottom to top; in order to effectively activate the P For the activity of doping impurities in the GaN layer, a transparent conductive layer of ITO with a thickness of 2000-2500 angstroms is evaporated on the surface of the epitaxial wafer by using a metal evaporation platform.

[0028] (2) Making P electrodes and N electrodes

[0029] Use photoresist as a mask to make P electrode patterns and N electrode patterns on the surface of the epitaxial wafer; remove the photoresist mask outside the electrode pattern by wet etching, anneal the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com