Electrodes for semiconductor devices and methods of forming the same

A semiconductor and electrode technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problem of difficulty in repeatedly manufacturing inclined field plates, etc., and achieve high breakdown voltage and low on-resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

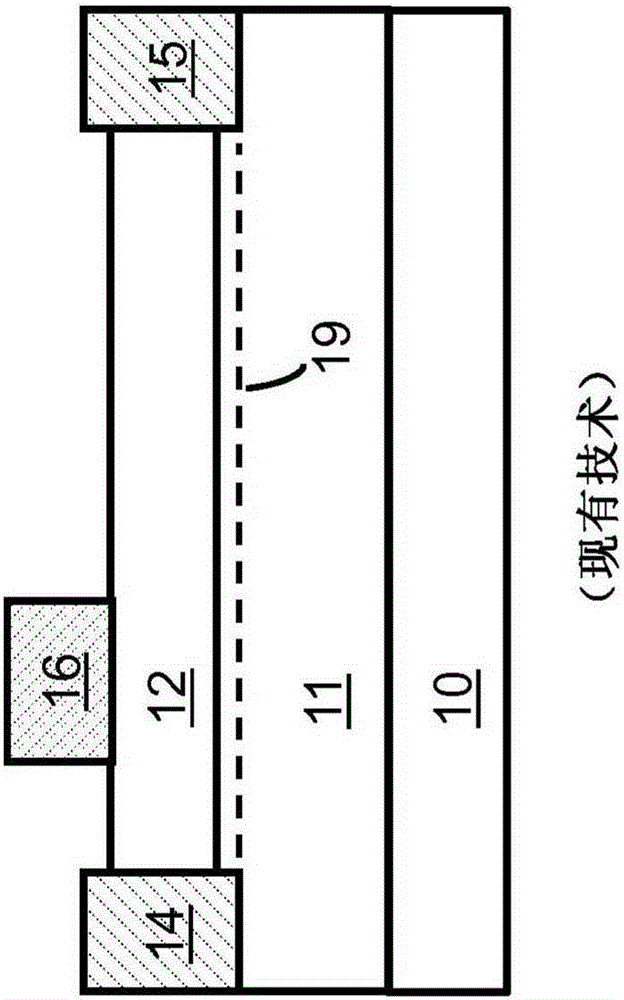

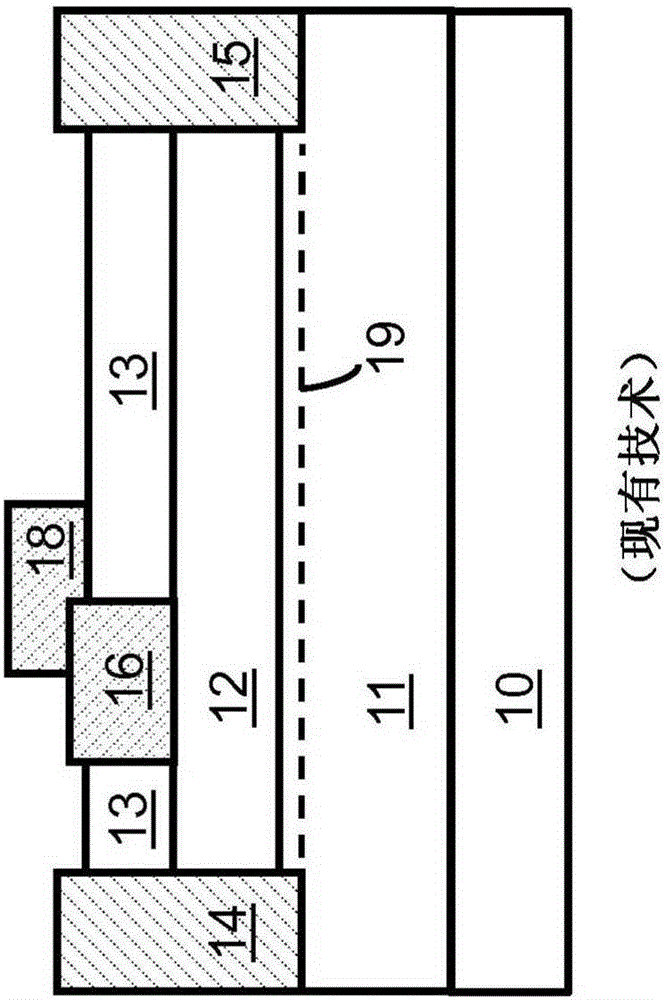

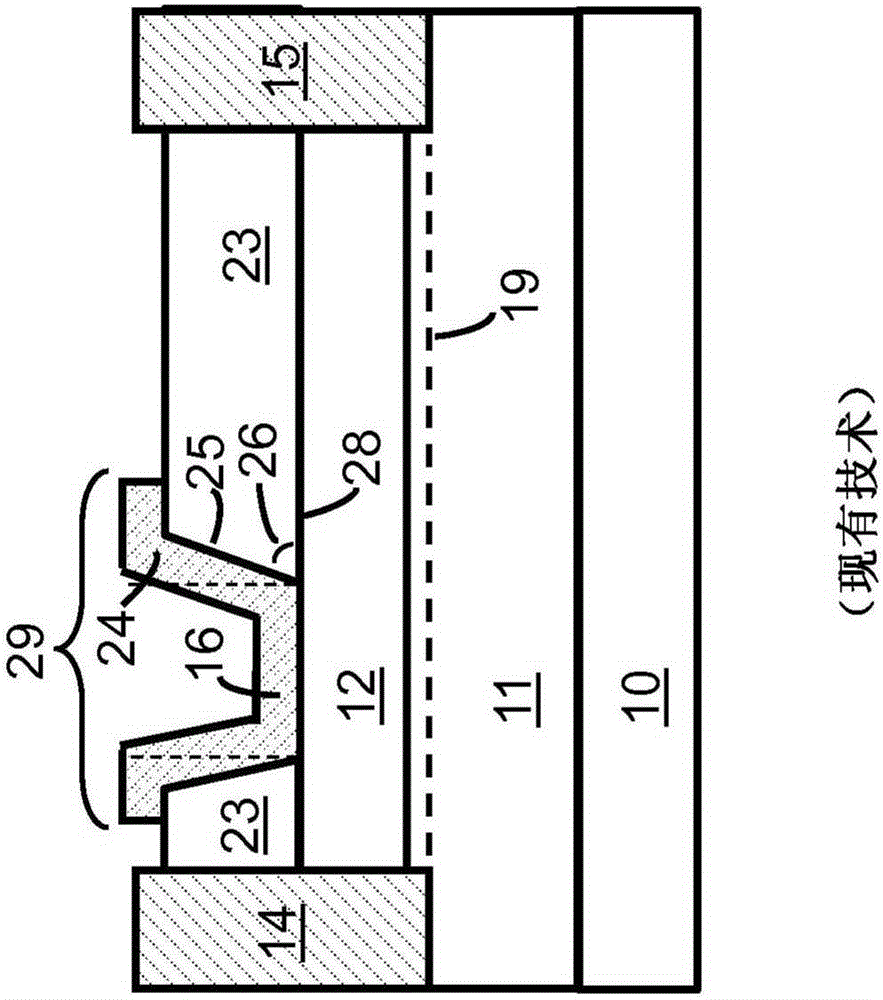

[0027] Transistors based on III-N heterostructures are described. The electrodes of the device are designed such that the device is reproducible, supports high voltage and low leakage current, and exhibits low on-resistance and low gate capacitance. A method of forming the electrode is also described. The III-N devices described herein may be high voltage devices suitable for high voltage applications. In such a high-voltage transistor, when the transistor is biased off (that is, the voltage on the gate relative to the source is less than the threshold voltage of the transistor), it can support at least all source-drain voltages less than or equal to its High voltage in the application used, for example the high voltage may be 100V, 300V, 600V, 1200V, 1700V or higher. When a high-voltage transistor is biased on (that is, the voltage on the gate relative to the source is greater than the threshold voltage of the transistor), it can conduct large currents with a low turn-on vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com