A preparation method of multi-enzyme hydrolysis pumpkin millet fermented drink

A multi-enzyme hydrolysis, pumpkin technology, applied in the function of food ingredients, food ingredients, food science and other directions, can solve the problems of single raw material, low molecular weight products, simple production process, etc., to achieve pure taste, simple production process and broad development Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

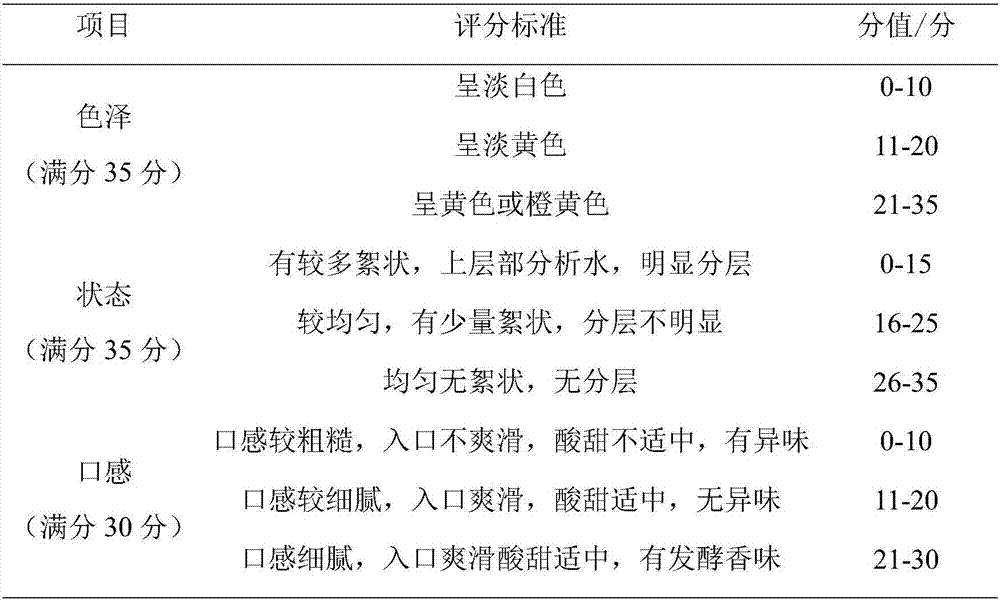

Examples

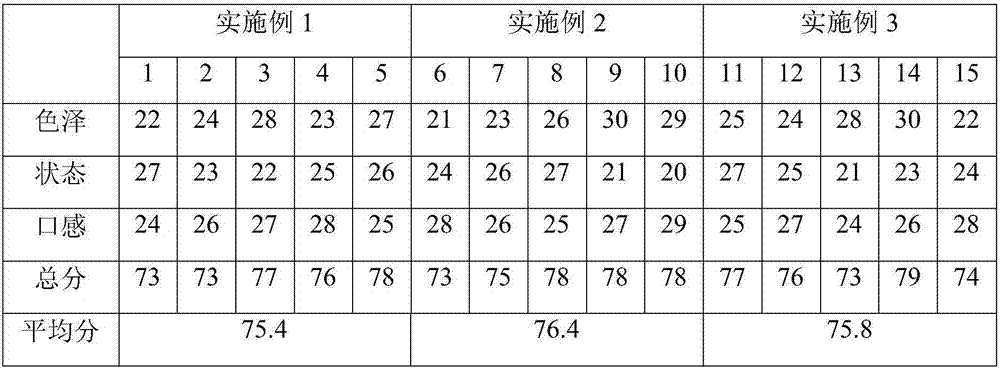

Embodiment 1

[0034] 1.1, pretreatment, beating

[0035] Thaw 200kg pumpkin slices in a microwave for 8 minutes, microwave power 300W, heat for 4 minutes, beat with water at a weight ratio of 1:8, and continue beating for 3 minutes when the pumpkin is completely broken; while processing the pumpkin, soak 100kg of millet for 60 minutes , and then millet and water are refined according to the weight ratio of 1:9.

[0036] 1.2. Enzyme hydrolysis

[0037] Add pectinase 20.0u / mL and glucoamylase 100u / mL to the pulped pumpkin liquid, heat and enzymolyze in a water bath at 45°C for 40min, then raise the temperature to 60°C and add complex cellulase 145u / mL, and enzymolyze for 150min ; Cool the millet liquid after beating to 50°C, add α-amylase 75.0u / mL to digest for 20min, lower the temperature to 45°C, add neutral protease 400u / mL, and digest for 40min.

[0038] 1.3. Filtration

[0039] Filter the pumpkin liquid and millet liquid after enzymolysis through a 100-mesh filter cloth, and keep the ...

Embodiment 2

[0053] 1.1, pretreatment, beating

[0054] Thaw 600kg pumpkin slices in microwave for 9 minutes, microwave power 340W, heat for 3 minutes, beat water with water at a weight ratio of 1:9, and continue beating for 4 minutes when the pumpkin is completely broken; while processing pumpkin, soak 200kg millet for 80 minutes , and then millet and water are refined according to the weight ratio of 1:8.

[0055] 1.2. Enzyme hydrolysis

[0056]Add pectinase 30.0u / mL and glucoamylase 95u / mL to the pulped pumpkin liquid, heat and enzymolyze in a water bath at 48°C for 50min, then raise the temperature to 60°C, add compound cellulase 150u / mL, and enzymolyze for 160min ; Cool the millet liquid after beating to 52°C, add α-amylase 70.0u / mL to digest for 25min, lower the temperature to 45°C, add neutral protease 395u / mL, and digest for 50min.

[0057] 1.3. Filtration

[0058] Filter the pumpkin liquid and millet liquid after enzymolysis through a 100-mesh filter cloth, and keep the filtrat...

Embodiment 3

[0072] 1.1, pretreatment, beating

[0073] Thaw 800kg pumpkin slices in microwave for 10min, microwave power 320W, heat again for 5min, beat with water at a weight ratio of 1:10, and continue beating for 5min when the pumpkin is completely broken; while processing pumpkin, soak 160kg of millet for 90min , and then millet and water are refined in a ratio of 1:10 by weight.

[0074] 1.2. Enzyme hydrolysis

[0075] Add pectinase 25.0u / mL and glucoamylase 105u / mL to the pulped pumpkin liquid, heat and enzymolyze in a water bath at 50°C for 60min, then raise the temperature to 60°C, add complex cellulase 155u / mL, and enzymolyze for 180min , Cool the millet liquid after beating to 55°C, add α-amylase 80.0u / mL to digest for 30min, lower the temperature to 45°C, add neutral protease 405u / mL, and digest for 60min.

[0076] 1.3. Filtration

[0077] Filter the pumpkin liquid and millet liquid after enzymolysis through a 100-mesh filter cloth, and keep the filtrate.

[0078] 1.4. Mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com