Production method and device for tobacco sheets

A technology of tobacco sheet and production method, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of high tightness, low bulk thickness of tobacco sheet, color difference, etc., achieve uniform drying, improve color uniformity, reduce The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

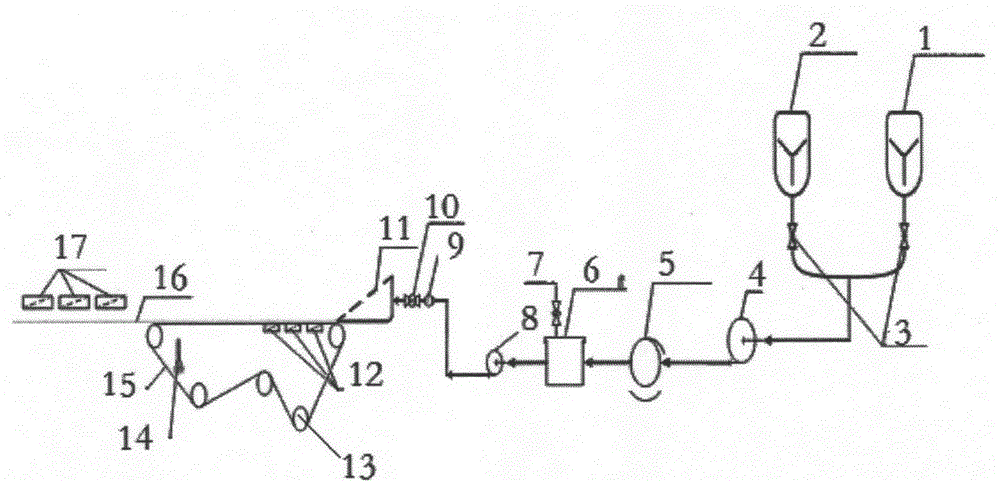

[0041] Such as figure 1 As shown, a tobacco sheet production device includes a slurry preparation unit 1 and a bubbly coating solution preparation unit 2, and the outlets of the slurry preparation unit 1 and the bubbly coating solution preparation unit 2 are connected by a pipeline The foam generator 5, the first pump 4 is connected in the pipeline between the outlet of the slurry preparation unit 1 and the foamy coating liquid preparation unit 2 and the foam generator 5, and the slurry preparation unit 1 And the pipeline between the outlet of the foam coating solution preparation unit 2 and the inlet of the first pump 4 is provided with a control valve 3, the foam generator 5 is connected to the slurry storage tank 6, and the slurry storage tank 6 is provided with a pressure relief The valve 7, the slurry storage tank 6 is connected to the second pump 8, and the second pump 8 is connected to the foam application device 11 through a pipeline, and a flow meter 9 and a control v...

Embodiment 2

[0044] A kind of production method of tobacco sheet, adopts the production device of tobacco sheet in embodiment 1, concrete steps are:

[0045] (1) After pan grinding and defibrating, the fiber length of the raw material pulp is 20 mm to 30 mm, the width is 1.5 to 2 mm, and the mass ratio is 6:2:2 for tobacco stems, tobacco dust and tobacco chips, and the ratio of water to liquid is 1: Under the conditions of 4, soak at 60°C for 30 minutes, extract for 35 minutes, filter through a 150-mesh sieve, and concentrate to obtain tobacco stems, tobacco powder, tobacco crushed extract, tobacco stems, tobacco powder and tobacco crushed residue; Refining obtains 232g tobacco stems, tobacco dust and tobacco crushed slurry, and the degree of beating is 35 ° SR;

[0046] (2) get the tobacco stem, tobacco powder, tobacco shreds extracting liquid of step (1) gained as tobacco coating liquid, add the described tobacco coating liquid of 97.4g in bubble coating liquid preparation unit 2, solid ...

Embodiment 3

[0050] A kind of production method of tobacco sheet, adopts the production device of tobacco sheet in embodiment 1, concrete steps are:

[0051] (1) After pan grinding and defibrating, the fiber length of the raw material pulp is 30 mm to 35 mm, the width is 1.5 to 2 mm, and the mass ratio is 5:2.5:2.5 for tobacco stems, tobacco dust and tobacco chips, and the ratio of water to liquid is 1: Soak at 65°C for 35 minutes under 4 conditions, extract for 30 minutes, filter through a 180-mesh sieve, and concentrate to obtain tobacco stems, tobacco powder, tobacco crushed extract, tobacco stems, tobacco powder and tobacco crushed residue; the tobacco stems, tobacco powder and tobacco crushed residue Refining obtains 184g tobacco stems, tobacco dust and tobacco crushed slurry, and the beating degree is 50 ° SR;

[0052] (2) get the tobacco stem, tobacco powder, tobacco shreds extracting liquid of step (1) gained as tobacco coating liquid, add the described tobacco coating liquid of 99...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com