Sodium bicarbonate injection double-layer aseptic vertical bag package system and preparation method thereof

A sodium bicarbonate and packaging system technology, which is applied in the field of pharmaceutical packaging, can solve problems such as shedding, changes, and difficulty in sealing the outer bag, and achieve the effect of facilitating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

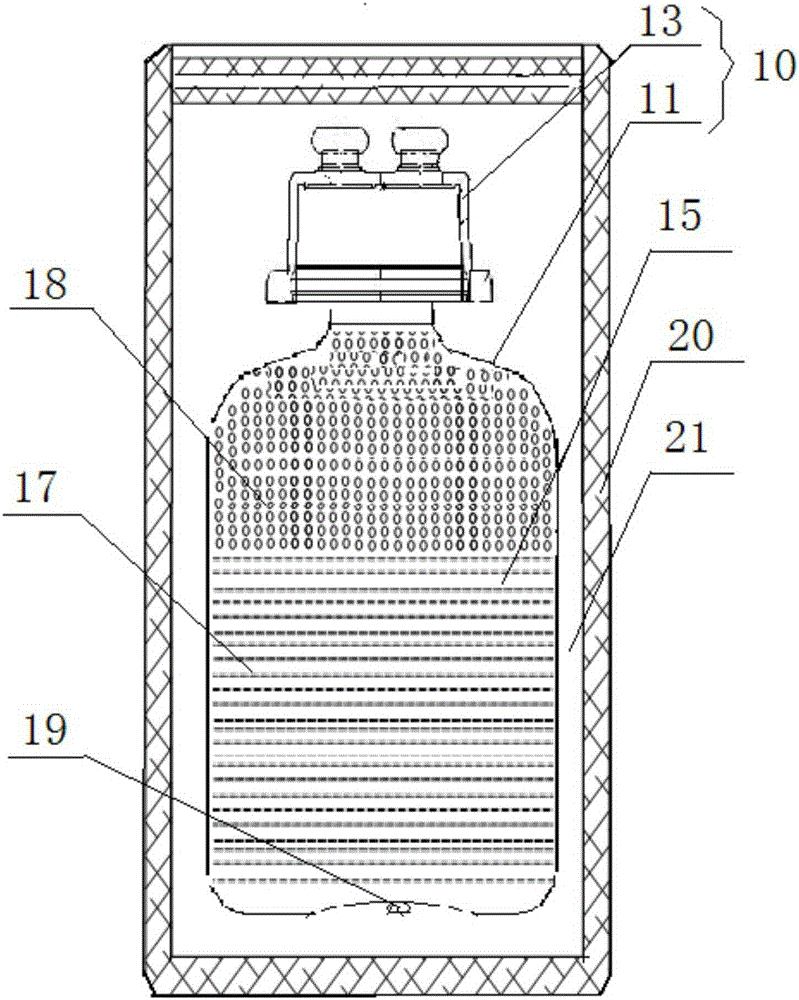

[0054] At the same time, the present invention also provides a preparation method of the above-mentioned sodium bicarbonate injection stand-up pouch packaging system, the preparation method includes the following steps: forming an internal medicine chamber 15 filled with sodium bicarbonate injection liquid medicine and carbon dioxide Gas polypropylene stand-up inner bag 10; put the polypropylene stand-up inner bag 10 into the barrier protection bag 20, seal and vacuum to form a double-layer structure stand-up bag; sterilize the double-layer structure stand-up bag , to obtain the sodium bicarbonate injection stand-up pouch packaging system.

[0055] In the above-mentioned method provided by the present invention, after putting the polypropylene stand-up inner bag 10 into the barrier protection bag 20, sealing and vacuuming is carried out to form a vacuum-sealed cavity in the barrier protection bag, thereby improving the problem of gas permeation at the same time , because it av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com