Converter shell mounting method

An installation method and converter technology, applied in auxiliary devices, transportation and packaging, auxiliary welding equipment, etc., can solve the problems of inability to guarantee the ellipticity of the shell and reduce the installation accuracy, so as to reduce the calibration work, improve the installation accuracy, Reduce the effects of working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

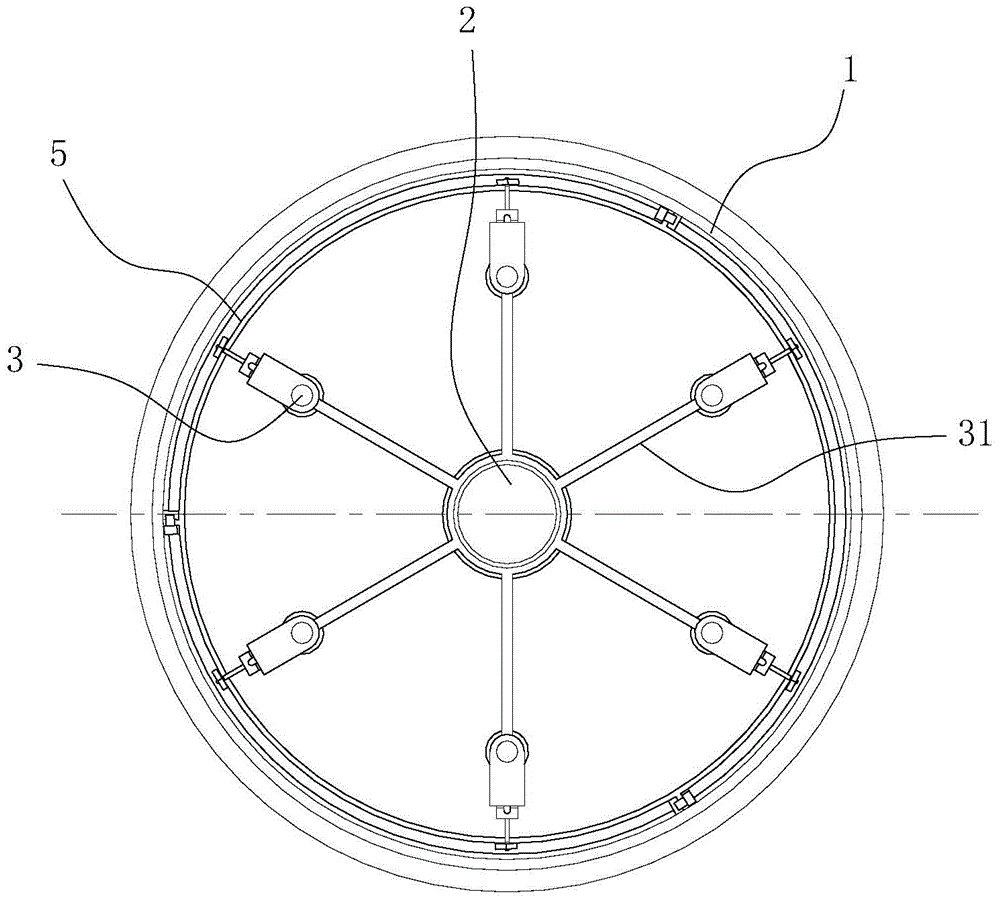

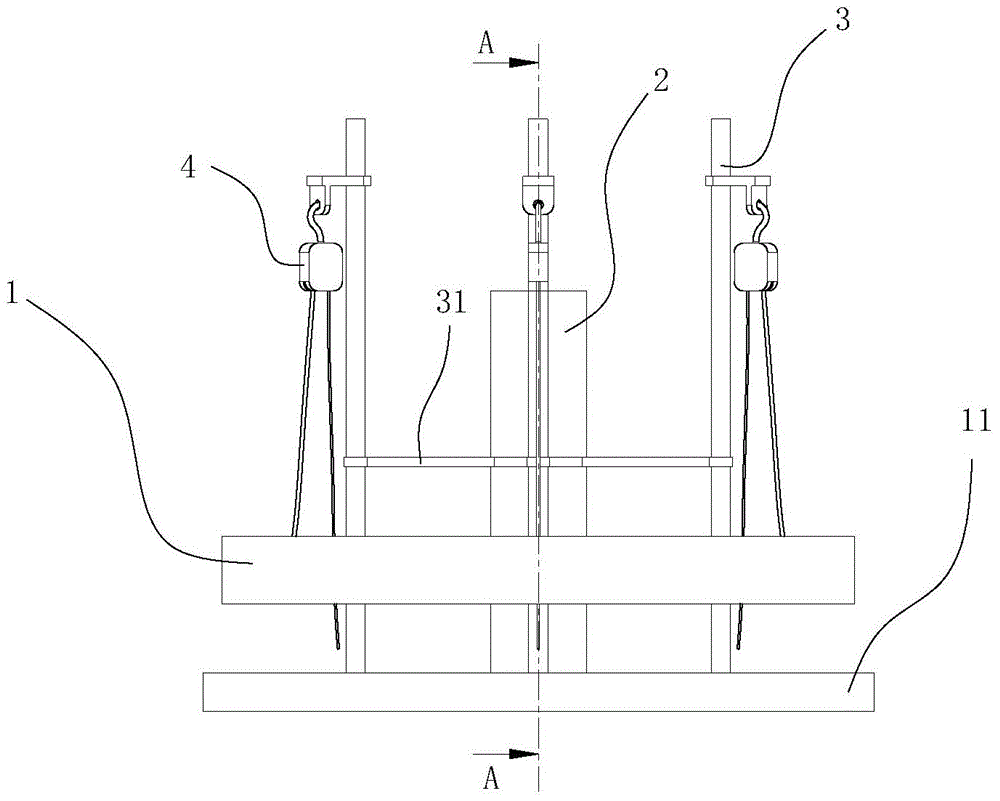

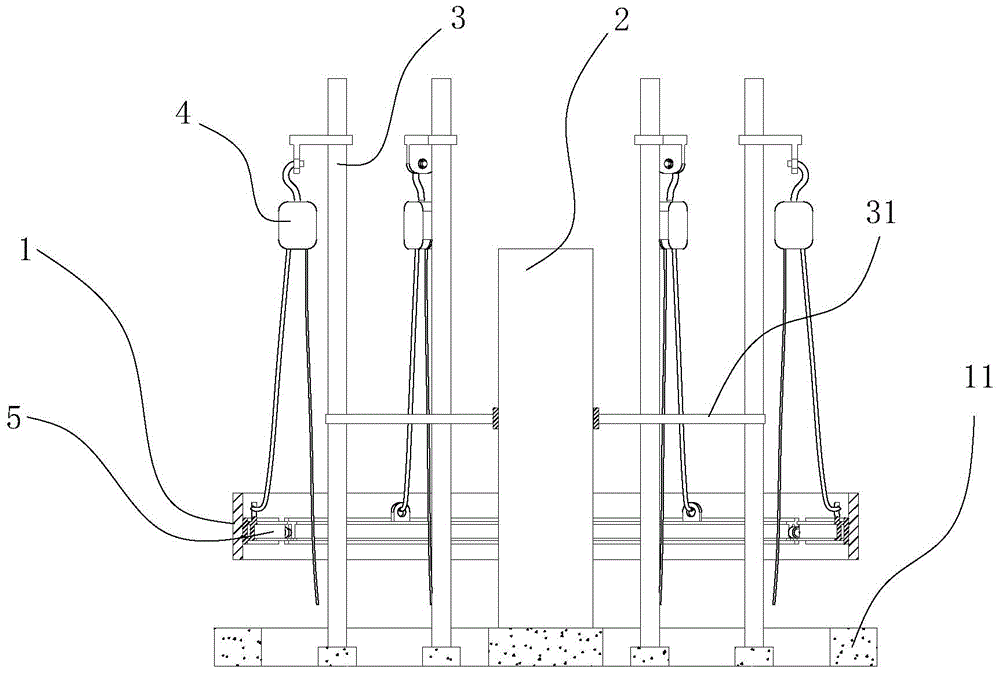

Examples

Embodiment

[0108] Install the stainless steel converter using the above installation method for the sulfur acid converter shell

[0109] 1. Production of tooling

[0110] 1.1 Selection of hoisting device and production of expansion ring

[0111] The hoisting device 4 adopts a chain hoist, and the expansion ring 5 adopts channel steel 51 to roll into a circle with the same inner diameter of the shell, and then divides it into three sections equally, and removes a part in the middle to place a screw jack 52 to adjust the expansion. The outer surface of the expansion ring 5 is pasted and welded with a connecting plate 53, and the connecting plate 53 is made of stainless steel to avoid direct contact of carbon steel with the stainless steel shell. Before lifting, the expansion ring 5 is tightened. At the same time, stainless steel ear plates are welded on the upper part of the shell expansion ring 5 to play the role of hanging ears to ensure that the force in the lifting process meets the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com