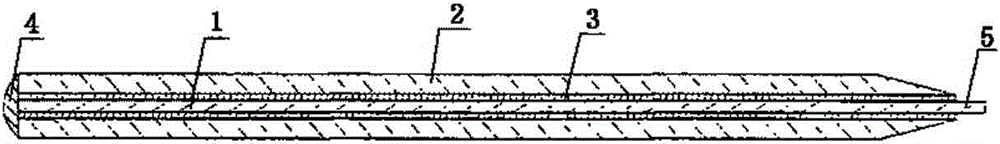

Environmentally friendly colored pencil

A color and pencil technology, applied in the field of stationery, can solve the problems of easy melting of pencil lead and waste of natural resources, and achieve the effect of improving hardness and coverage, no dross, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: prepare red pencil lead

[0018] Components: sodium thiosulfate 7g, sodium carbonate 0.565g, phenolphthalein 1.186g, carboxymethylcellulose (CMC) 1g.

[0019] Preparation method: mix phenolphthalein and sodium carbonate, add absolute ethanol dropwise to adjust to a thick paste, then pour molten sodium thiosulfate into it and stir evenly, then add carboxymethyl cellulose (CMC) and stir evenly, pour Put it in the mold, let it dry, take it out, and it's ready.

[0020] Effect: Using the Wolff-wilborn pencil hardness test method, the hardness of the pencil core is 5H, with high chroma and good coverage. Withstand temperature 45℃.

Embodiment 2

[0021] Embodiment 2: prepare red pencil lead

[0022] Components: sodium thiosulfate 7g, sodium carbonate 0.421g, phenolphthalein 0.883g, carboxymethylcellulose (CMC) 0.9g, clay 0.8g.

[0023] Preparation method: mix phenolphthalein and sodium carbonate, add absolute ethanol dropwise to adjust to a thick paste, then pour molten sodium thiosulfate into it and stir evenly, then add carboxymethyl cellulose (CMC) and clay and stir evenly , pour into the mold, let it dry, take it out, and that's it.

[0024] Effect: Using the Wolff-wilborn pencil hardness test method, the hardness of the pencil core is 4H, the chroma is very high, and the coverage is very good. Withstand temperature 45℃.

[0025] Effect: Using the Wolff-wilborn pencil hardness test method, the hardness of the pencil core is 4H, the chroma is very high, and the coverage is very good. Withstand temperature 45℃.

Embodiment 3

[0026] Embodiment 3: prepare yellow pencil lead

[0027] Components: sodium thiosulfate 7g, sodium carbonate 0.812g, m-nitrophenol 1.077g, carboxymethylcellulose (CMC) 1.5g.

[0028] Preparation method: mix m-nitrophenol and sodium carbonate, add absolute ethanol dropwise to adjust to a thick paste, then pour molten sodium thiosulfate into it and stir evenly, then add carboxymethyl cellulose (CMC) and stir Evenly, pour into the mold, let it dry, take it out, and that's it.

[0029] Effect: Using the Wolff-wilborn pencil hardness test method, the hardness of the pencil core is 3H, with high chroma and good coverage. Withstand temperature 45℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com