High-definition EVA (ethylene vinyl acetate copolymer) laminated glass middle film and preparation method thereof

A laminated glass, high-definition technology, applied in the direction of film/sheet adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem of low clarity of the interlayer film of EVA laminated glass, and achieve Eliminates fogging and improves clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

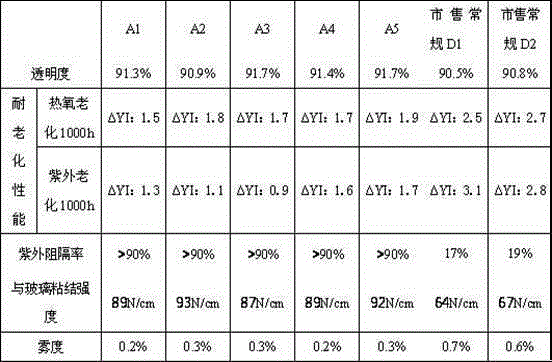

Examples

Embodiment 1

[0017] A high-definition EVA laminated glass interlayer film, comprising the following components in parts by mass: vinyl acetate content of 28%, 100 parts of EVA resin with a melt index of 15, 2,5-di-tert-butyl peroxide-2,5 -1.0 parts of dimethylhexane, 0.6 parts of γ-methacryloxypropyltrimethoxysilane, 0.6 parts of N,N'-diisopropylcarbodiimide, 2-hydroxy-4-n-octyloxy 0.3 parts of benzophenone, 0.3 parts of tris(mononylbenzene and dinonylbenzene mixed ester) of phosphorous acid.

[0018] The above-mentioned materials are uniformly mixed according to the proportion provided by the present invention, put into a tape casting machine, extruded and cast to form a film. The resulting product is labeled A1.

Embodiment 2

[0020] A high-definition EVA laminated glass interlayer film, comprising the following components in parts by mass: vinyl acetate content of 33%, 100 parts of EVA resin with a melt index of 10, 1.5 parts of tert-butyl cumene, β-( 0.5 parts of 3,4-ethoxycyclohexane) ethyltrimethoxysilane, 0.6 parts of bis(2,6-diisopropylphenyl)carbodiimide, 2-hydroxy-4-n-octyloxy 0.5 part of benzophenone, 0.4 part of polysuccinic acid (4-hydroxy-2,2,6,6,-tetramethyl-1 piperidine ethanol ester).

[0021] The above-mentioned materials are uniformly mixed according to the proportion provided by the present invention, put into a tape casting machine, extruded and cast to form a film. The resulting product is labeled A2.

Embodiment 3

[0023] A high-definition EVA laminated glass interlayer film, comprising the following components in parts by mass: a vinyl acetate content of 33%, 100 parts of EVA resin with a melt index of 7, 1.0 parts of tert-butyl peroxycarbonate-2-ethylhexyl 0.5 parts of γ-glycidoxypropyltrimethoxysilane, 0.3 parts of dicyclohexylcarbodiimide, 3,5 di-tert-butyl-4-hydroxybenzoic acid-2,4-di-tert-butylbenzene 0.3 part of ester, 0.3 part of 1:1 mixture of pentaerythritol diisodecyl phosphite and polysuccinic acid (4-hydroxy-2,2,6,6,-tetramethyl-1 piperidine ethanol ester).

[0024] The above-mentioned materials are uniformly mixed according to the proportion provided by the present invention, put into a tape casting machine, extruded and cast to form a film. The resulting product is labeled A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com