Method for preparing high fructose corn syrup by using glucose syrup

A technology of glucose syrup and high fructose syrup, applied in the direction of fermentation, can solve the problem of low fructose fructose content, etc., and achieve the effects of increasing profits, realizing healthy operation, improving product competitiveness and resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

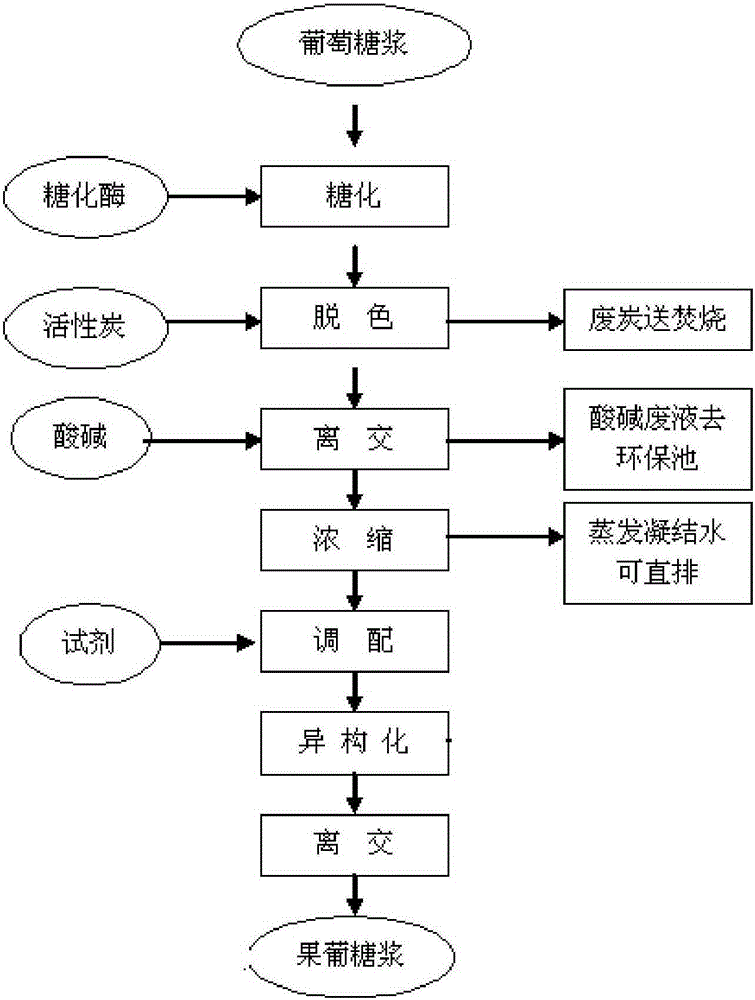

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of method utilizing glucose syrup to prepare fructose syrup

[0031] A method utilizing glucose syrup to prepare fructose syrup, comprising the steps of:

[0032] (1) Saccharification: take glucose syrup (usually Ds: 20-30%), add 250ml / m 3 Glucoamylase, saccharification at 60°C for 12 hours. Requirements: oligosaccharides <5%;

[0033] (2) Decolorization: Add 3% (w / v) activated carbon and stir at 55-65°C for 45 minutes, and filter to remove carbon at 5-10 μm. Requirements: transparent and colorless, UV<0.8;

[0034] (3) Pre-separation: the syrup after carbon removal is passed through an anion and cation exchange resin column. Requirements: colorless and transparent, UV<0.5, conductance γ<20μs / cm.

[0035] (4) Concentration: vacuum concentration to Ds: 45-55%. Other requirements: UV<1.0 (Ds: 30%), γ<20μs / cm (Ds: 30%).

[0036] (5) Preparation: Use sodium carbonate to adjust the pH to 7.5-7.8, add 0.15 g / L of sodium metabisulfite, add 0.6 g / L of...

Embodiment 2

[0041] (1) Saccharification: take glucose syrup (usually Ds: 15-20%), add 175ml / m 3 Glucoamylase, saccharification at 60°C for 12 hours. Requirements: oligosaccharides <5%;

[0042] (2) Decolorization: Add 3% (w / v) activated carbon and stir at 55-65°C for 45 minutes, and filter to remove carbon at 5-10 μm. Requirements: transparent and colorless, UV<0.8;

[0043] (3) Pre-separation: the syrup after carbon removal is passed through an anion and cation exchange resin column. Requirements: colorless and transparent, UV<0.5, conductance γ<20μs / cm.

[0044] (4) Concentration: vacuum concentration to Ds: 45-55%. Other requirements: UV<1.0 (Ds: 30%), γ<20μs / cm (Ds: 30%).

[0045] (5) Preparation: Use sodium carbonate to adjust the pH to 7.5-7.8, add 0.15 g / L of sodium metabisulfite, add 0.6 g / L of magnesium sulfate heptahydrate, and stir well.

[0046] (6) Isomerization: enter the isomerization column (0.5×2m, isomerase 73kg) at a constant temperature of 55°C, with an average s...

Embodiment 3

[0050] (1) Saccharification: take glucose syrup (usually Ds: 30-35%), add 300ml / m 3 Glucoamylase, saccharification at 60°C for 12 hours. Requirements: oligosaccharides <5%;

[0051] (2) Decolorization: Add 3% (w / v) activated carbon and stir at 55-65°C for 45 minutes, and filter to remove carbon at 5-10 μm. Requirements: transparent and colorless, UV<0.8;

[0052] (3) Pre-separation: the syrup after carbon removal is passed through an anion and cation exchange resin column. Requirements: colorless and transparent, UV<0.5, conductance γ<20μs / cm.

[0053] (4) Concentration: vacuum concentration to Ds: 45-55%. Other requirements: UV<1.0 (Ds: 30%), γ<20μs / cm (Ds: 30%).

[0054] (5) Preparation: Use sodium carbonate to adjust the pH to 7.5-7.8, add 0.15 g / L of sodium metabisulfite, add 0.6 g / L of magnesium sulfate heptahydrate, and stir well.

[0055] (6) Isomerization: enter the isomerization column (0.5×2m, isomerase 73kg) at a constant temperature of 55°C, with an average s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com