Anode polarization and coloration treatment method of aluminum alloy extinguisher valve body

A technology of anodic polarization and treatment method, which is applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., which can solve the problems affecting the need for emergency fire extinguishing, affecting the shelf life of fire extinguishers, and loss of sealing performance, and achieves light weight and reduced The effect of equipment input and prevention of fire extinguishing agent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing the implementation details of the present invention are described as follows:

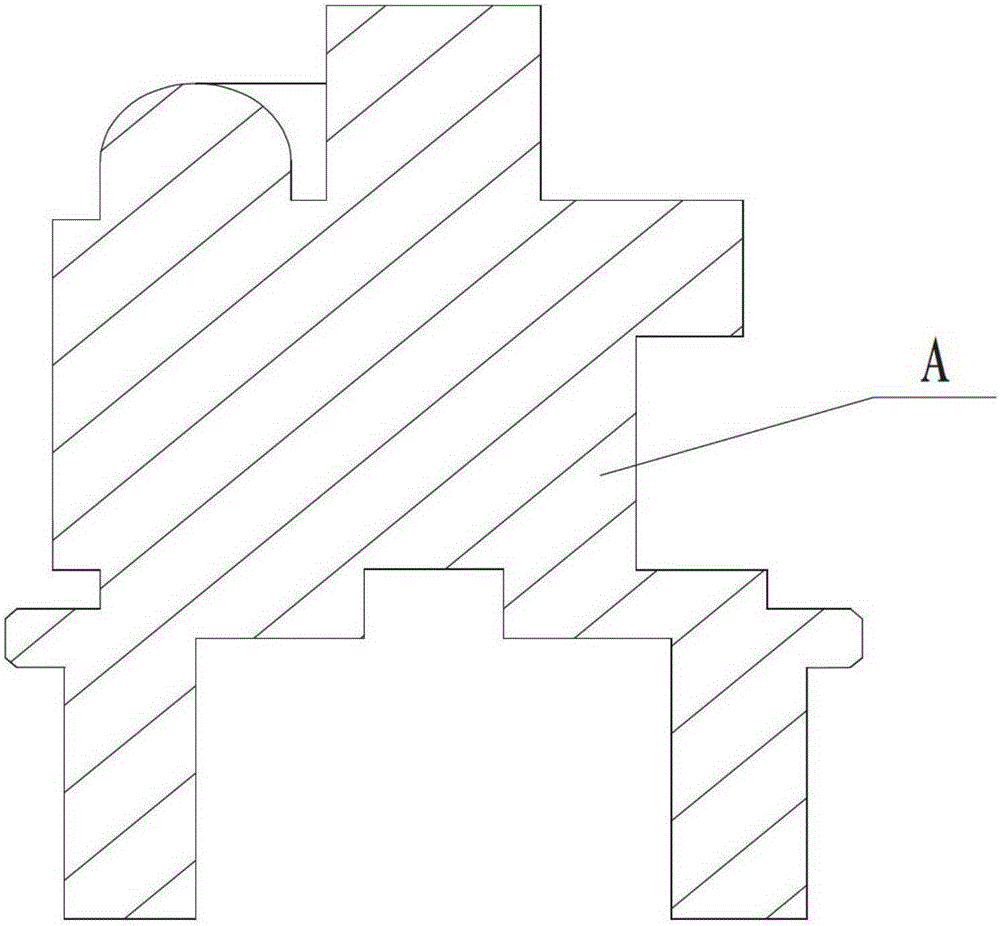

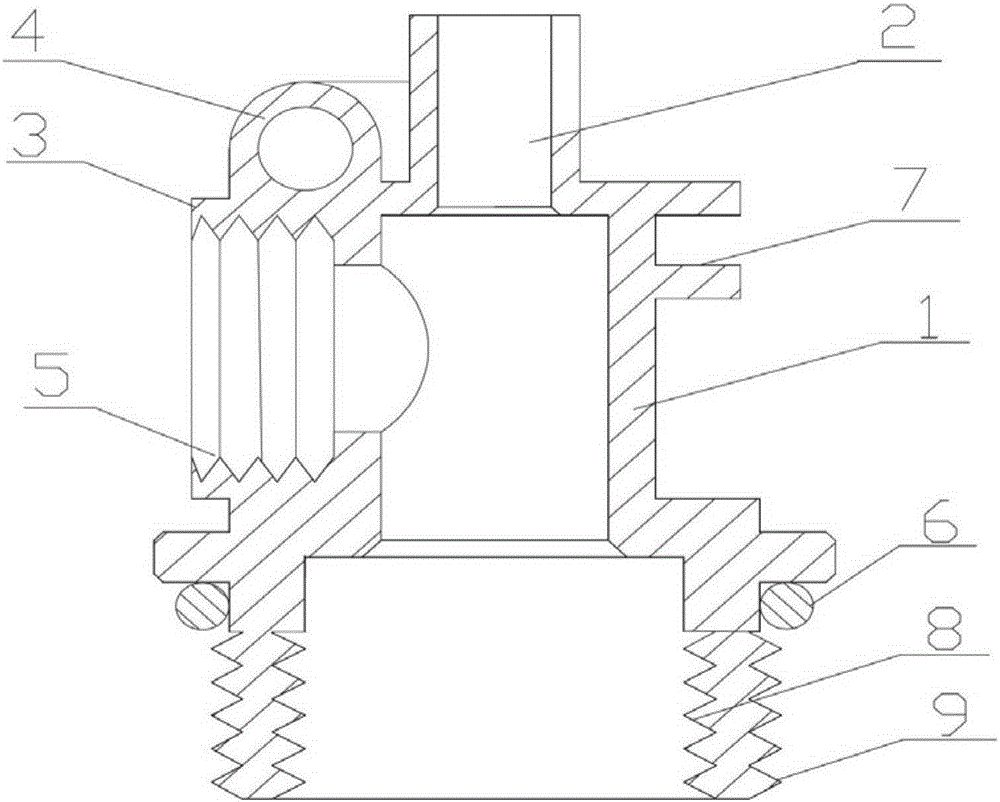

[0016] Such as figure 1 As shown, a multi-directional forged aluminum alloy fire extinguisher valve body, the forged valve body part A is made of 6061 aluminum alloy, and its chemical composition: Mg0.8-1.2%, Si0.4-0.8%, Cu0 .15-0.4%, Fe0.7%, Mn0.15%, Zn0.25%, Cr0.04-0.35%, Ti0.15%, and the balance is aluminum. The manufacturing process is as follows:

[0017] 1. Forging: The technological process is: blanking—heating to 490°C—multidirectional die forging—edge trimming;

[0018] 2. Heat treatment: carry out solution aging treatment to the aluminum alloy after forging. See Table 1 below for solution treatment examples of the present invention, and see Table 2 for artificial aging examples. After comparison, the solution temperature is finally determined to be 520°C, held for 6 hours, and aged The temperature is 170°C and the temperature is kep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com