Method for preparing water absorbent fiber

A technology of water-absorbing fiber and cellulase, which is applied in the post-treatment modification of cellulose pulp, etc., can solve the problems of limiting the water-absorbing performance of cellulose-based water-absorbing materials, and achieve the effects of simple operation, high water-absorbing capacity and improving water-absorbing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing water-absorbent fibers, comprising the steps of:

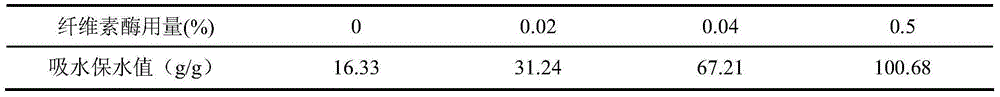

[0022] 1) Measure four parts of poplar bleached chemical thermomechanical pulp with a mass concentration of 3% to adjust the pH to 5.5, stir at a rotating speed of 500rpm, one part does not add cellulase, and the remaining three parts add cellulase to make the fiber The mass fractions of cellulase were 0.02%, 0.04% and 0.5%, respectively, and treated in a water bath at 50° C. for 1 hour to obtain cellulase pretreated slurry;

[0023] 2) Mix methyl vinyl ether / maleic anhydride copolymer and polyethylene glycol 3350 with water to obtain solution 1, mix solution 1 with cellulase pretreatment slurry, stir for 1 hour, and dry at 65°C Until its quality no longer changes; place (i.e. solidify) at a temperature of 130°C for 6.5 minutes to obtain water-absorbing fibers, the cellulase pretreatment slurry, methyl vinyl ether / maleic anhydride copolymer, polyethylene glycol The mass ratio of alcohol 3350 is 1...

Embodiment 2

[0029] A method for preparing water-absorbent fibers, comprising the steps of:

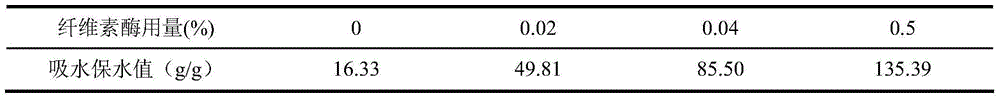

[0030] 1) Take four parts of maple high-yield pulp with a mass concentration of 1% to adjust the pH to 6.5, stir at a speed of 300 rpm, add cellulase to one part, and add cellulase to the remaining three parts to make the cellulase The mass fractions are 0.02%, 0.04% and 0.5%, respectively, and are incubated in a water bath at 45°C for 0.5h to obtain a cellulase pretreated slurry;

[0031] 2) Mix methyl vinyl ether / maleic anhydride copolymer and polyethylene glycol 1450 with water to obtain solution 1, mix solution 1 with cellulase pretreatment slurry, stir for 0.5h, and set the temperature at 50°C Dry until its quality does not change; place (i.e. solidify) at a temperature of 140°C for 2 minutes to obtain water-absorbing fibers, the cellulase pretreatment slurry, methyl vinyl ether / maleic anhydride copolymer, polyethylene glycol The mass ratio of alcohol 1450 is 1:0.5:0.12.

[0032] The water-...

Embodiment 3

[0037] A method for preparing water-absorbent fibers, comprising the steps of:

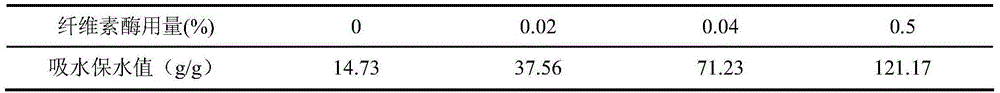

[0038] 1) Take four parts of poplar bleached kraft pulp with a mass concentration of 5% to adjust the pH to 5, stir at a rotating speed of 800rpm, one part does not add cellulase, and the remaining three parts add cellulase to make the cellulase The mass fractions are 0.02%, 0.04% and 0.5%, respectively, and are incubated in a water bath at 45°C for 3 hours to obtain a cellulase pretreated slurry;

[0039] 2) Mix methyl vinyl ether / maleic anhydride copolymer and polyethylene glycol 3350 with water to obtain solution 1, mix solution 1 with cellulase pretreatment slurry, stir for 1.5h, and set the temperature at 70°C Dry until its quality does not change; place (i.e. solidify) at a temperature of 120°C for 15 minutes to obtain water-absorbing fibers, the cellulase pretreatment pulp, methyl vinyl ether / maleic anhydride copolymer, polyethylene glycol The mass ratio of alcohol 3350 is 1:2:0.3.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com