A Structural System of Field Beam Column Cap and Beamless Floor Slab

A beam-column and system technology, applied in the field of field beam-column cap and beamless floor structure system, can solve the problem that the column cap and the lattice column cannot be effectively connected, the deformation of the enclosure structure is increased, and the over-excavation depth is increased. problems, to achieve the effect of reasonable stress, reasonable structural stress and reduction of over-excavation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

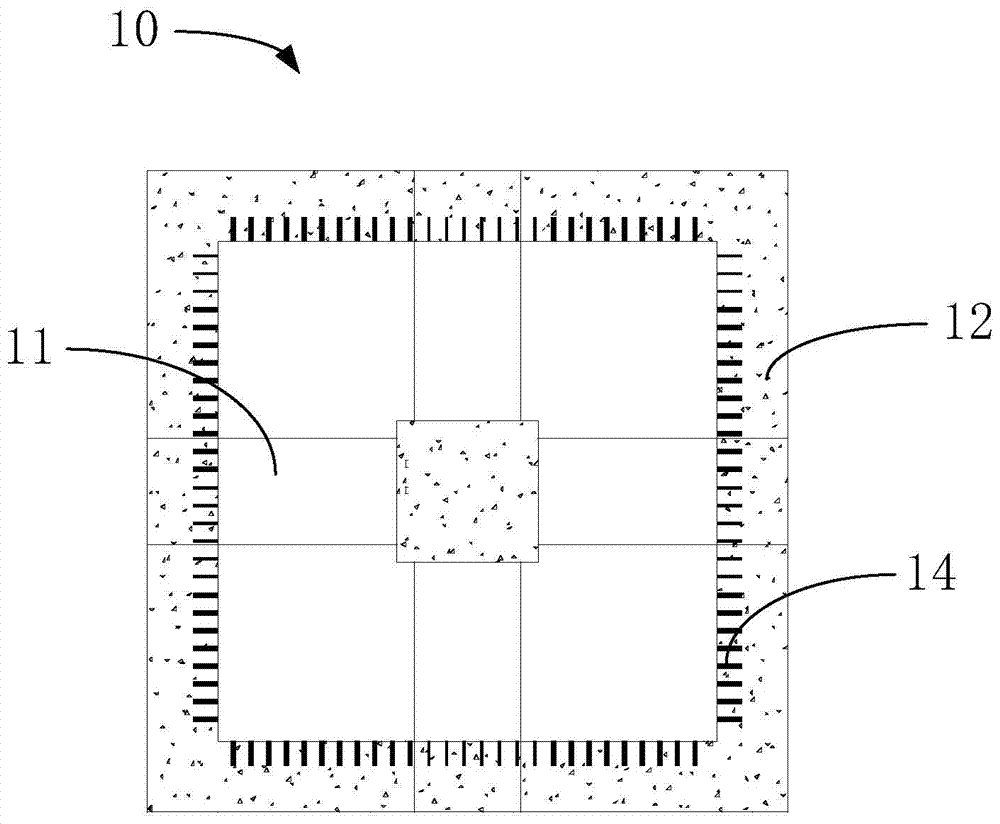

[0030] The cross-shaped beam column cap provided by the invention, such as figure 1 and figure 2 As shown, it is applied to the construction of the straight method, including the cross beam 11 and the cross beam 11 peripheral mouth ring beam 12, and the four ends of the cross beam 11 are respectively connected to the middle of each side of the mouth ring beam 12. Points are just connected to form a cross-shaped beam. Specifically, the cross-shaped beam is bound with steel bars. Please combine Figure 5 , the upper surface of the cross beam 11 is flush with the upper surface of the structural plate 20, the mouth circle beam 12 is located at the bottom of the structural plate 20, and the lower surface of the cross beam 11 is flush with the mouth circle The lower surface of the beam 12 is flush. The present invention effectively connects the cross beam 11 with the concrete column, effectively combines the structural plate 20 with the structural floor slab poured in the cross b...

Embodiment 2

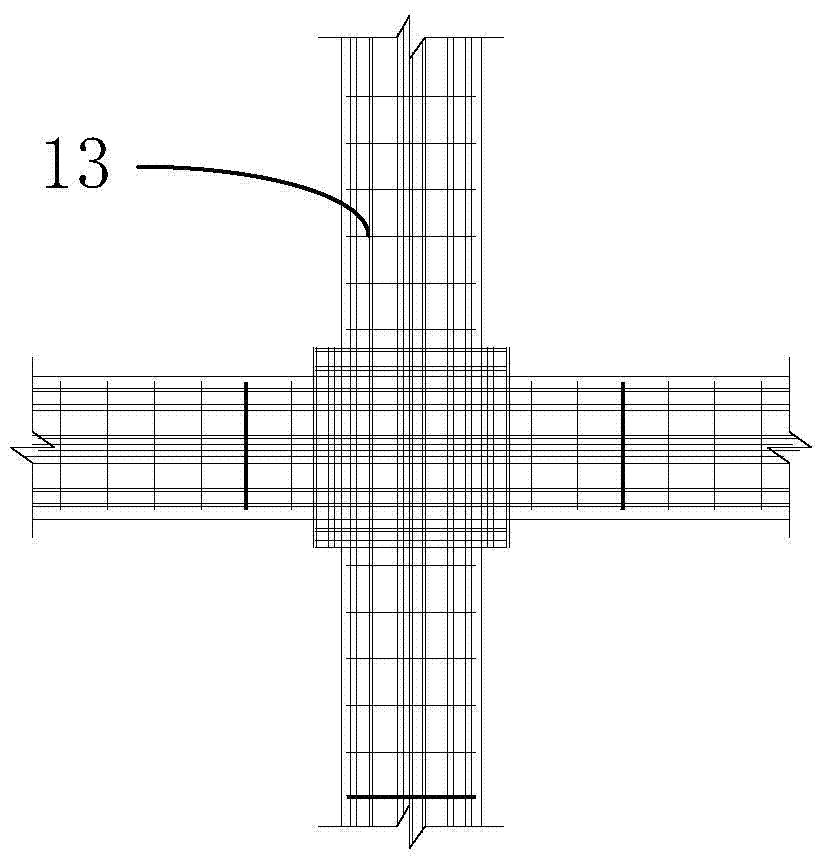

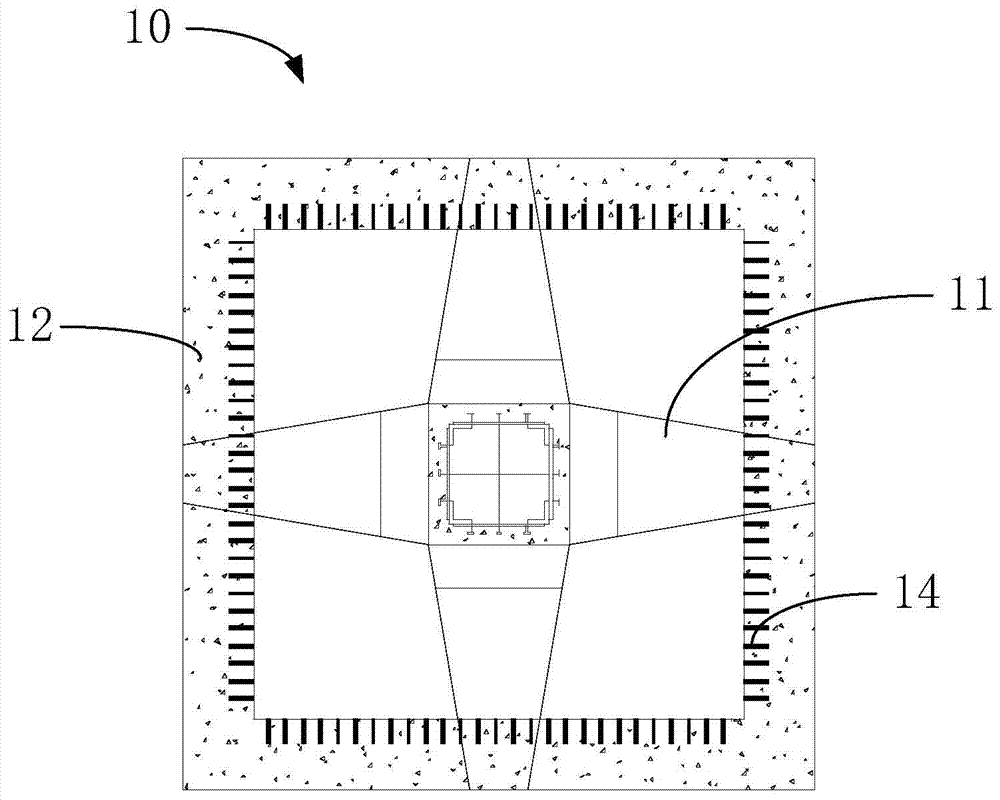

[0035] The difference between this embodiment and Embodiment 1 is: Please refer to image 3 and combine Figure 5 , the cross-shaped beam column cap 10 in this embodiment is applied in the reverse construction method, and the cross beam 11 is gradually reduced in width from the intersection point. The distribution of rib 13 is as follows Figure 4 As shown, a beam system is formed at the top of the lattice column 30, so that the checking calculation of the punching shear is converted into the checking calculation of the shear bearing capacity, and the rationality of the force is increased; in addition, for the basement constructed by the reverse construction method, the The over-excavation depth at each floor of the foundation pit reduces the deformation of the enclosure structure and improves the progress of the beamless floor in the reverse construction method.

[0036] Preferably, please continue to refer to Figure 5 , the cross beam 11 is provided with a corbel support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com