Detachable pipe bundle flue type heat collection equipment and method

A flue type and equipment technology, which is applied in the field of detachable tube bundle flue type heat collecting equipment, can solve the problems of scrapping and replacing the whole set of units, gathering in the dead angle position of the tube bundle support plate, reducing the heat exchange efficiency of the equipment, etc., and shortening the maintenance downtime. time, reduced maintenance workload, and the effect of good product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in conjunction with accompanying drawing and specific embodiment:

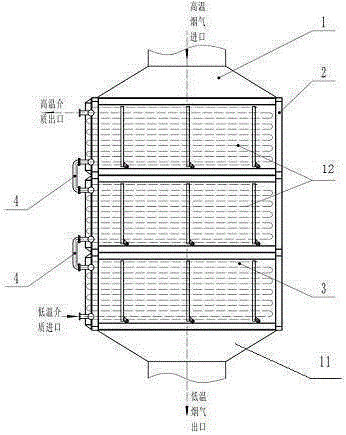

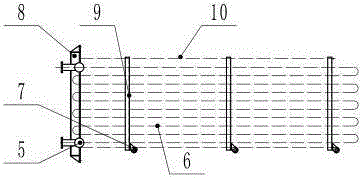

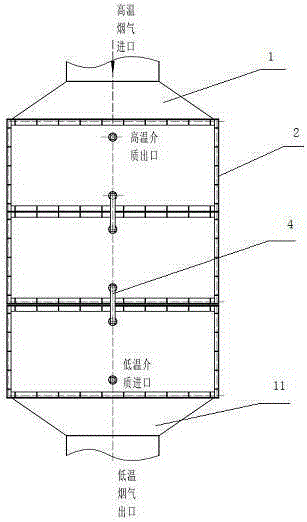

[0033] Such as figure 1 , 2 , 3, 4, 5, a detachable tube bundle flue type heat collection equipment, the heat collection equipment includes: high temperature flue gas inlet duct 1, frame assembly 2, heat exchange tube bundle assembly, low flue gas outlet Air duct 11; the high-temperature flue gas inlet air duct 1 communicates with the low-temperature flue gas outlet air duct 11 through the flue gas duct 3 of the heat exchange tube bundle assembly located in the frame assembly 2; the flue gas inlet air duct 1, The flue gas outlet duct 3 can be designed according to the shape and cross-sectional area of the flue and the shape of the connecting surface with the frame assembly 2 .

[0034] The heat exchange tube bundle assembly is composed of a plurality of detachable heat exchange tube bundle units 12 connected in series along the direction of the flue, or composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com