Tempered glass process operation management system

A tempered glass and management system technology, applied in the direction of manufacturing computing system, general control system, control/adjustment system, etc., can solve the problems of high risk factor, affecting efficiency, high demand, etc., achieve clear quality standards, realize production efficiency and quality layered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

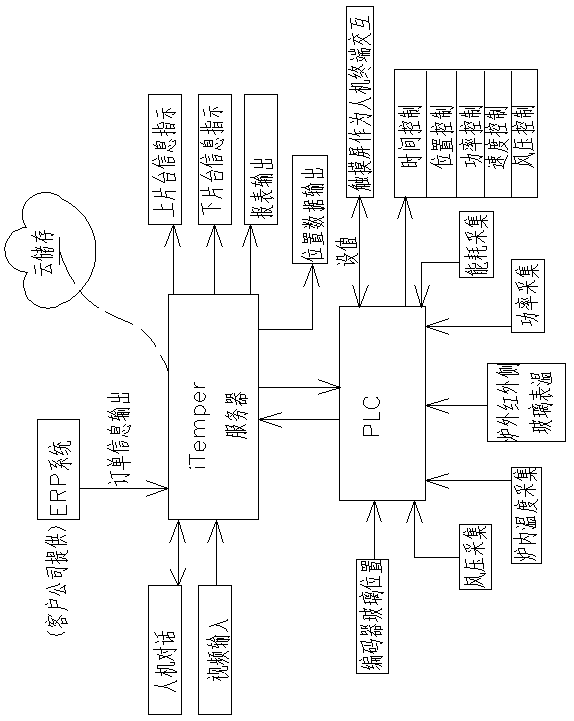

[0012] Embodiment 1: with reference to attached figure 1 . A tempered glass process operation control management system, two-way data exchange between iTemper server, PLC controller and man-machine dialogue terminal, iTemper server is equipped with ERP system information, video signal and man-machine dialogue terminal receiving port, and iTemper server is equipped with Loading table information indication, unloading table information indication, report information output port, and drive command output port; ERP system inputs order information to iTemper server, video terminal inputs current operation live information to iTemper server, man-machine dialogue terminal communicates with iTemper server The provided data is confirmed or corrected, and the iTemper server outputs the information indication of the loading table, the information indication of the unloading table, and the report information to the monitor for display or display and Print, the PLC controller will input t...

Embodiment 2

[0019] Embodiment 2: On the basis of Embodiment 1, a tempered glass process operation control management system operation method, ERP system inputs order information to iTemper server or video terminal inputs order information to iTemper server, iTemper server according to ERP system or video terminal The input information automatically selects the tempered glass standard from the tempered glass quality standard database built in the iTemper server, and selects the optimized process parameters corresponding to the standard in the tempered glass process parameter selection library built in the iTemper server according to the standard and outputs it to the HMI Dialogue terminal, man-machine dialogue terminal confirms or modifies the optimized process parameters, and then returns to the iTemper server, iTemper server instructs tempered glass according to the instructions confirmed by the man-machine dialogue terminal or the PLC controller according to the instructions confirmed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com