Nafion grafted polyvinyl azole composite proton exchange membrane and preparation method thereof

A polyvinyl azole, proton exchange membrane technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, solid electrolyte fuel cells, etc., can solve problems such as the decline of proton conductivity, inhibit the permeation of methanol, optimize hydrogen bonding The effect of network and preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

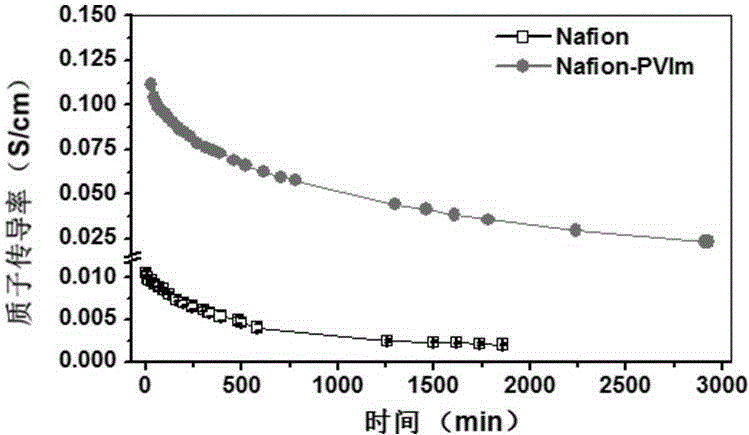

Embodiment 1

[0025]Add 0.5g of 1-vinylimidazole (the final product is labeled as "Nafion-PVIm") and 0.06g of bipyridine to 10mL of commercially available Nafion solution, stir well, repeat the freeze-degas-dissolve step three times to remove the Oxygen; then, add 0.1g CuBr to the above system, repeat the freezing-degassing-dissolving step three times in the same way to further remove the oxygen in the system, and react at 80°C for 24h; then, the product Nafion is obtained through dialysis and drying -PVIm; Nafion-PVIm was dissolved in DMF to form a homogeneous solution with a mass volume ratio of 5%; the solution was carefully poured into a mold and quickly placed in a 70°C oven, starting from 70°C for 2 hours and then slowly The temperature was raised to 120°C to remove the solvent; vacuum was applied, and the temperature of the vacuum oven was set at 120°C and kept for 16h; finally, the membrane was first soaked with 3wt% H 2 o 2 The solution was soaked at 70°C for 2h, followed by 1MH ...

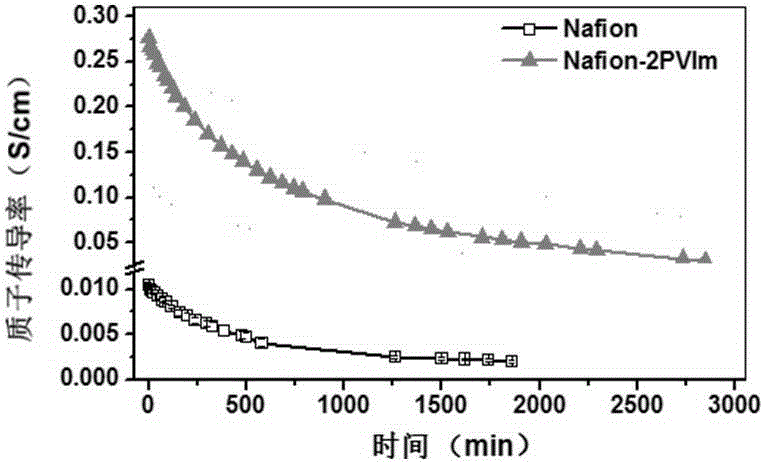

Embodiment 2

[0028] Add 1.0 g of 1-vinylimidazole (the final product is labeled as "Nafion-2PVIm") and 0.06 g of bipyridine to 10 mL of commercially available Nafion solution, stir well, repeat the freezing-degassing-dissolving step three times to remove the Oxygen; then, add 0.1g CuBr to the above system, repeat the freezing-degassing-dissolving step three times in the same way to further remove the oxygen in the system, and react at 80°C for 24h; then, the product Nafion is obtained through dialysis and drying -2PVIm; Dissolve Nafion-2PVIm in DMF to form a homogeneous solution with a mass volume ratio of 5%; carefully pour the solution into a mold and quickly place it in a 70°C oven, start from 70°C for 2 hours and then slowly The temperature was raised to 120°C to remove the solvent; vacuum was applied, and the temperature of the vacuum oven was set at 120°C and kept for 16h; finally, the membrane was first soaked with 3wt% H 2 o 2 The solution was soaked at 70°C for 2h, followed by 1M...

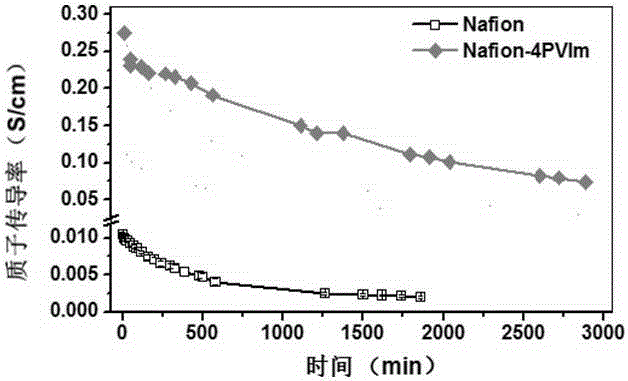

Embodiment 3

[0031] Add 2.0g of 1-vinylimidazole (the final product is labeled as "Nafion-4PVIm") and 0.06g of bipyridine to 10mL of commercially available Nafion solution, stir well, repeat the freezing-degassing-dissolving step three times to remove the Oxygen; then, add 0.1g CuBr to the above system, repeat the freezing-degassing-dissolving step three times in the same way to further remove the oxygen in the system, and react at 80°C for 24h; then, obtain the product and Nafion-4PVIm; Dissolve Nafion-4PVIm in DMF to make a homogeneous solution with a mass volume ratio of 5% respectively; carefully pour the solution into a mold and quickly place it in a 70°C oven, start from 70°C for 2h Slowly raise the temperature to 120°C to remove the solvent; evacuate, set the temperature of the vacuum oven at 120°C and keep it for 16h; finally, the membrane is first soaked with 3wt% H 2 o 2 The solution was soaked at 70°C for 2h, followed by 1MH 2 SO 4 Convert the membrane to H at 80 °C for 1 h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com