Graphite carbon brush forming machine

A technology of graphite carbon and molding machine, which is applied in the field of electric brush manufacturing, can solve the problems of low working efficiency of graphite carbon brushes, achieve the effects of small footprint and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

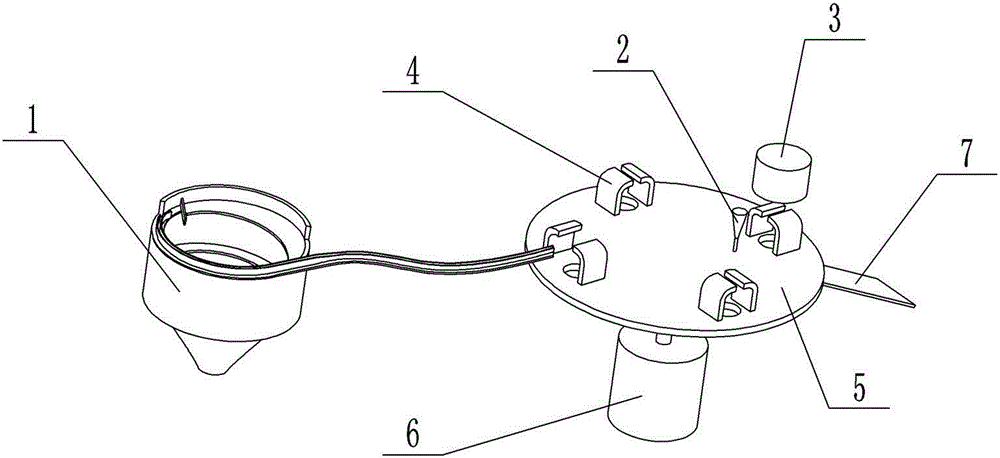

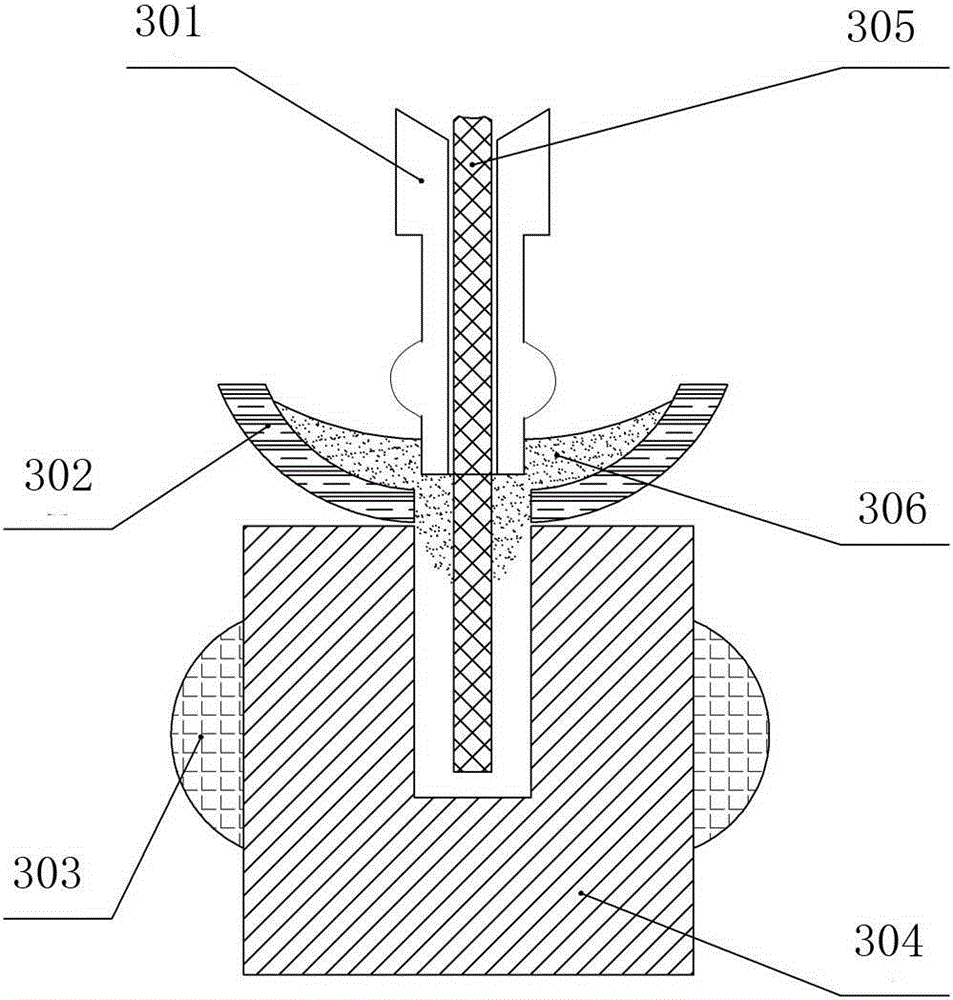

[0021] The reference signs in the drawings of the description include: feeding mechanism 1, drilling machine 2, filling device 3, gripper 4, workbench 5, servo motor 6, inclined plate 7, pressure rod 301, barrel 302, hydraulic gripper 303, blank 304, wire 305, raw material 306.

[0022] Such as figure 1 Shown, a kind of graphite carbon brush forming machine comprises feeding mechanism 1, drilling machine 2, the first lifter for drilling device lifting, filling device 3, the second lifter for filling device 3 lifting, workbench 5 , servo motor 6, swash plate 7, and the PLC that can control the above-mentioned equipment. The models of the first lifter and the second lifter are both QTD5020 boom-type lifters. The feeding mechanism 1 is a vibrating plate. The baffle, the baffle is hinged on the vibrating plate and driven by a miniature servo motor. The workbench 5 is a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com