A device for surface modification of powder filler and using method thereof

A technology of powder filler and feeding device, applied in fibrous fillers, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of low processing efficiency and high energy consumption, and achieve high processing efficiency, low energy consumption, and economic The effect of the process of de-feeding and powder transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

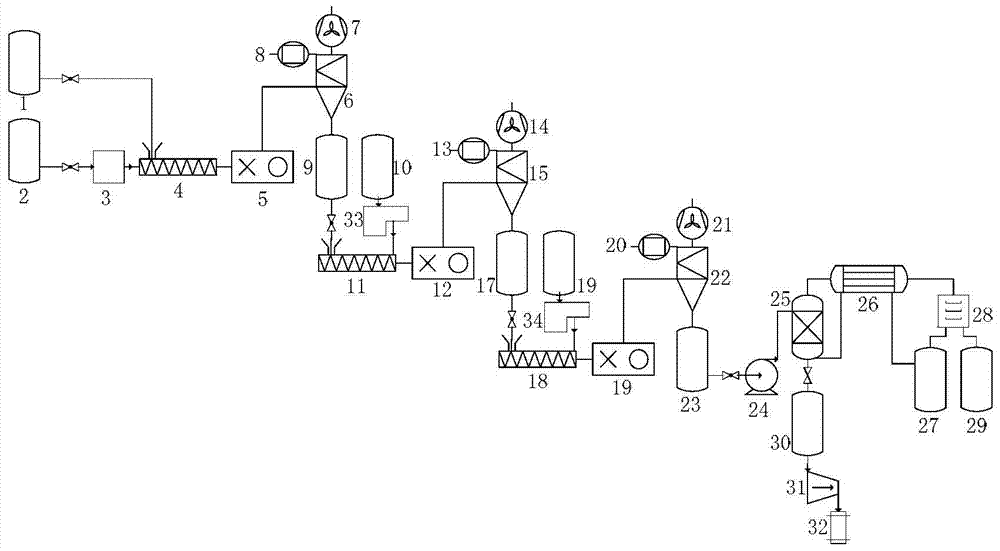

[0056] Embodiment 1, the device of powder filler surface modification

[0057] Such as figure 1 Shown is the device for surface modification of powder fillers according to the present invention, which includes powder feeding devices, liquid feeding devices, modifiers and collecting devices, and also includes drying devices for drying modified fillers, and also includes drying devices for packaging modified fillers. Added packaging equipment. The modification collection device includes the modification machine and the material collection equipment connected to it. The material metering equipment includes the powder packing material tank Ⅰ1 and the motor-driven screw metering pump Ⅰ4 connected to it, the modifier material tank Ⅱ2 and the metering pump Ⅱ3 connected to it, and the screw metering pump Ⅰ4 is connected to the metering pump Ⅱ3 , The metering pump II3 is connected with the modification machine 5. The reformer 5 is connected with the collector 6, and the collector 6 ...

Embodiment 2

[0073] Embodiment 2, adopt the device of surface modification of powder filler to modify the surface of powder filler

[0074] The method for modifying the surface of the powder filler by using the device for surface modification of the powder filler of the present invention:

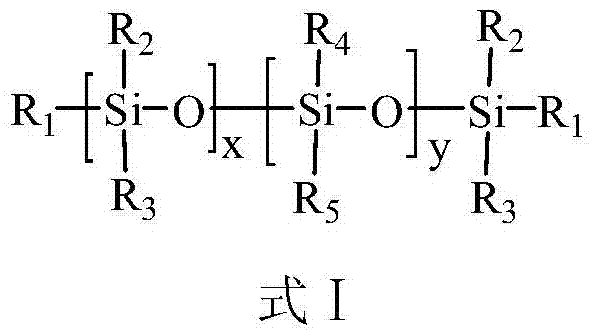

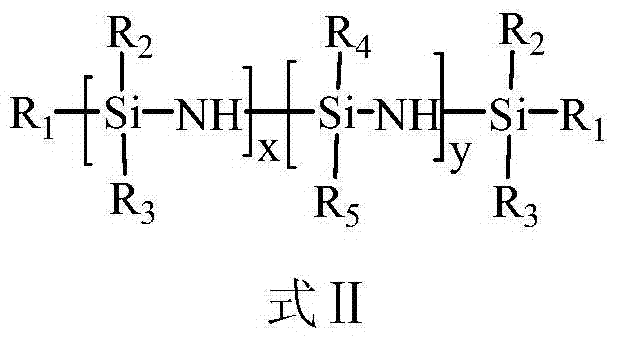

[0075] 1) The precipitated silica Z-142 (produced by Rhodia) in the powder filler material tank I1 flows to the modifier 5 under the control of the frequency of 50 Hz through the screw metering pump I4, and at the same time the modifier material tank II2 The modifier hexamethyldisilazane flows through the metering pump II3 at a frequency of 10 Hz to the screw metering pump I4 and mixes with white carbon black and then flows through the modifier 5, driven by the motor of the modifier 5 at a speed of 1500 rpm. The high-speed rotation in the processing chamber of the modification machine makes hexamethyldisilazane mix evenly and adsorb on the surface of precipitated silica Z-142 during the continuous rando...

Embodiment 3

[0079] Embodiment 3, adopt the device of surface modification of powder filler to modify the surface of powder filler

[0080] The method for modifying the surface of the powder filler by using the device for surface modification of the powder filler of the present invention:

[0081] 1) The precipitated silica Z-142 in the powder packing material tank I1 flows to the modifier 5 through the screw metering pump I4 under the frequency control of 50 Hz, and the octamethylcyclotetrasilicon in the modifier material tank II2 The oxane flows through the metering pump II3 to the screw metering pump I4 at a frequency of 5 Hz, mixes with white carbon black, and then flows through the reformer 5. Driven by the motor of the reformer 5 at a speed of 1500 rpm, it flows at a high speed in the processing chamber of the reformer. Rotate, so that the hydrogen-containing silicone oil is mixed evenly during the continuous random collision with the precipitated silica Z-142 and adsorbed on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com