Energy-saving method for preparing yellow phosphorus, potassium salt, sodium carbonate and alumina from potassium-containing phosphate rock

A technology of sodium carbonate and alumina, which is applied in the chemical industry, can solve problems such as insufficient use of heat, inability to produce high-quality yellow phosphorus, and failure to meet the requirements of yellow phosphorus enterprises, so as to achieve comprehensive production cost reduction, wide market application range, and outstanding energy-saving effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

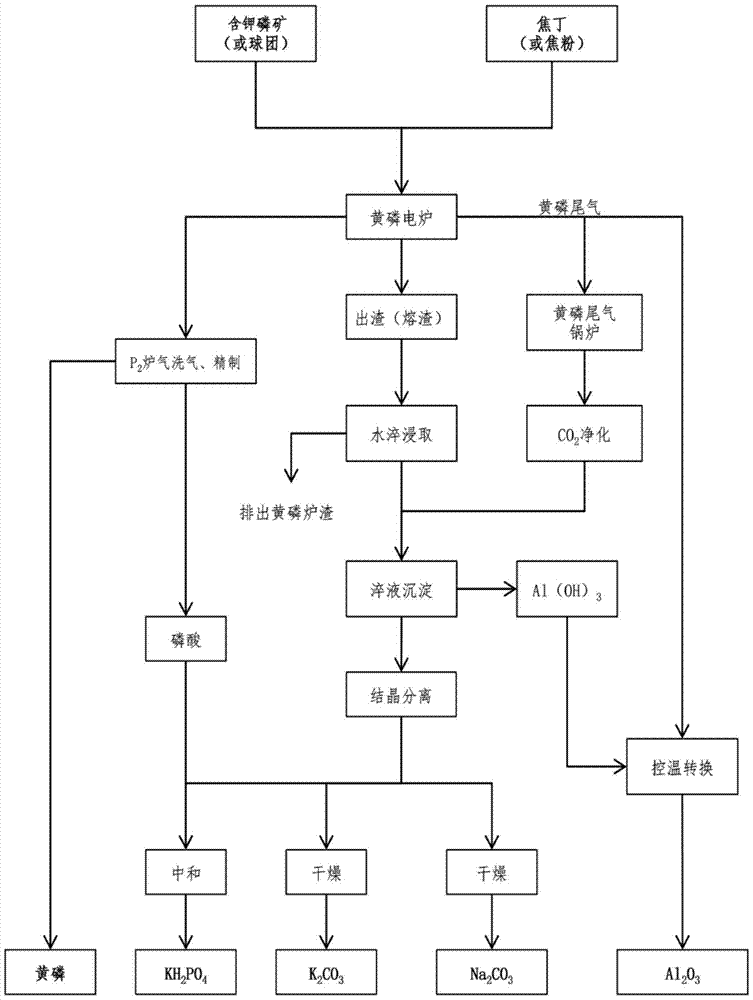

Image

Examples

Embodiment 1

[0058] with P 2 o 5 Content is 23.19%, SiO 2 content of 21.82%, CaO content of 32.58%, K 2 O content is 2.51%, Na 2 Trace O content, CO 2 Potassium-containing phosphate rock (15-25mm) with a content of 3.96% and coke (3-25mm) with a fixed carbon content of 80% are added to the yellow phosphorus electric furnace according to the ratio of potassium-containing phosphate rock: coke diced = 1000:146.

[0059] According to the method of the present invention, 15kt / a yellow phosphorus production plant can produce yellow phosphorus 15kt annually, K 2 CO 3 4.7kt, Al 2 o 3 3.5kt. produced K 2 CO 3 Can be further processed to generate 9.25kt of KH 2 PO 4 .

Embodiment 2

[0061] with P 2 o 5 content of 20.5%, SiO 2 content of 22.2%, CaO content of 33.0%, K 2 O content is 1.89%, Na 2 O content is 0.44%, CO 2 Potassium-containing phosphate rock (15-25mm) with a content of 4.0% and coke (3-25mm) with a fixed carbon content of 80% are added to the yellow phosphorus electric furnace according to the ratio of potassium-containing phosphate rock: coke diced = 1000:131.5.

[0062] According to the method of the present invention, 10kt / a yellow phosphorus production plant can produce yellow phosphorus 10kt annually, K 2 CO 3 2.9kt, Al 2 o 3 2.6 kt, Na 2 CO 3 520t. produced K 2 CO 3 Can be further processed to generate 5.7kt KH 2 PO 4 .

Embodiment 3

[0064] with P 2 o 5 content of 19.5%, SiO 2 content of 21.9%, CaO content of 32.7%, K 2 O content is 2.29%, Na 2 O content is 0.15%, CO 2 Potassium-containing phosphate rock (15-25mm) with a content of 4.0% and coke (3-25mm) with a fixed carbon content of 80% are added to the yellow phosphorus electric furnace according to the ratio of potassium-containing phosphate rock: coke diced = 1000:126.

[0065] According to the method of the present invention, 20kt / a yellow phosphorus production plant can produce yellow phosphorus 20kt annually, K 2 CO 3 7.0kt, Al 2 o 3 5.5kt, Na 2 CO 3 360t. produced K 2 CO 3 It can be further processed to generate 13.8kt KH 2 PO 4 .

[0066] Compared with the existing potassium feldspar-lime sintering method, the aforementioned embodiments of the present invention can save energy and reduce consumption and CO 2 The emission reduction indicators are shown in Table 1:

[0067] Table 1

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com