Treating method and treating device for highly-emulsified oily sewage

The technology of a treatment device and a treatment method is applied to the oily sewage treatment device and the oily sewage separation and treatment field containing emulsified oil, so as to prevent back-dissolution, facilitate re-aggregation and increase, accelerate floating, and increase the coverage area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

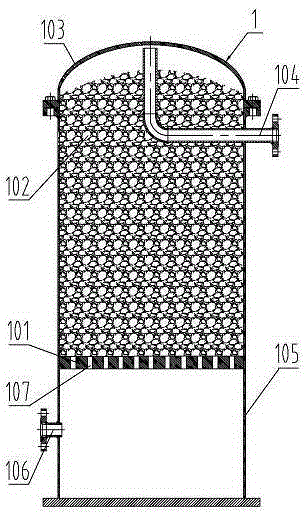

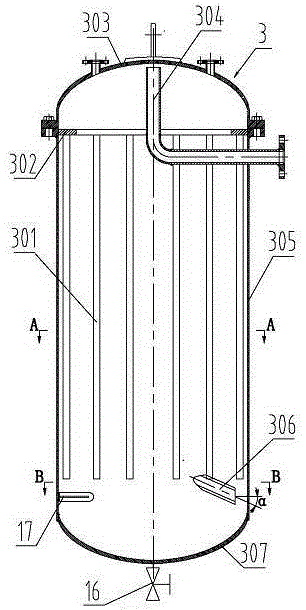

[0049] exist figure 1 In the oily wastewater treatment process shown, the heavily emulsified oily wastewater is taken as an example. The demulsifier cylinder 105 of the demulsifier 1 is fixed with a material separation orifice 101, and the demulsification orifice 101 separates the demulsifier cylinder 105 into a demulsifier filling cavity located at the upper part of the cylinder and an oil chamber located at the lower part. The sewage buffer chamber is filled with a solid-phase demulsifier 102 in the demulsifier filling chamber, and the solid-phase demulsifier 102 is a solid slow-release demulsifier. The sewage pump 19 pumps heavily emulsified oily sewage into the oily sewage buffer chamber of the demulsifier 1, and the oily sewage passes through the partition through hole 107 on the partition orifice 101 and flows evenly through the demulsifier filling chamber to break the solid phase. The gaps of the emulsion 102 are fully and evenly skimmed by the massive solid-phase demu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com