Treatment method of dimethoate pesticide production wastewater

A technology for the production of wastewater and treatment methods, applied in the field of water treatment, can solve the problems of increasing phosphorus removal costs, wasting water resources, and difficult treatment, and achieve the effects of improving denitrification efficiency and biochemical effects, reducing treatment costs, and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

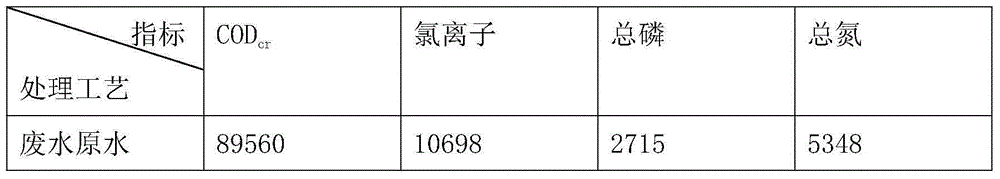

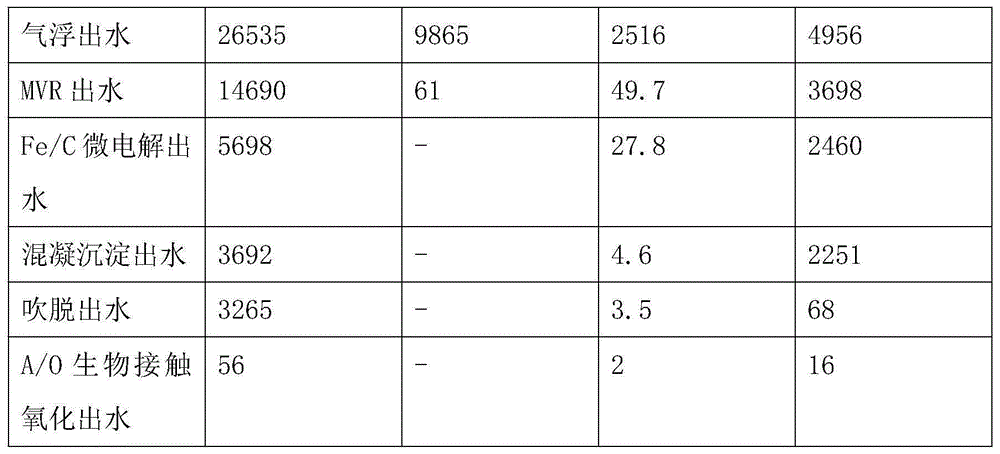

[0028] Specific implementation case: Dimethoate production wastewater from a pesticide factory in Hunan. The pesticide wastewater is high-concentration and refractory organic wastewater produced during the production process of Dimethoate. Its COD cr At 5000-100000, the salt content is 5%-30% (mass percentage), the content of total phosphorus is 100-10000mg / L, and the total nitrogen is 50-10000mg / L.

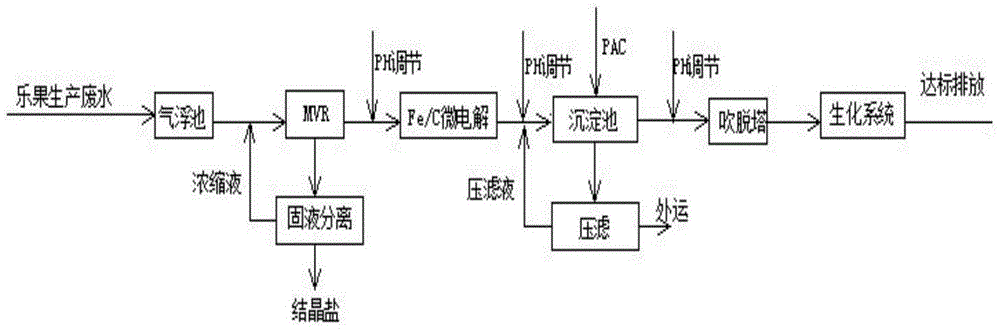

[0029] Such as figure 1 Shown, the processing method that above-mentioned dimethoate production wastewater is processed, concrete steps are as follows:

[0030] (1) Air flotation treatment: Wastewater enters the air flotation tank, first passes through the dosing air flotation device, adjusts the pH value of the wastewater to between 6.5 and 7.5, and adds PAC with a mass fraction of 1 to 3% and PAM with a mass fraction of 1‰, After passing through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com