A reinforcement and protection agent for crisp powder murals and its preparation and reinforcement method

A technology for reinforcement and murals, applied in the preservation of paintings, decorative arts, etc., can solve the problems of material aging, poor penetration of reinforcement reagents, and fouling of the paint layer on the surface of murals, and achieve the reduction of water holding and hygroscopicity, and the inhibition of salt damage. The effect is obvious and the water volatility is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

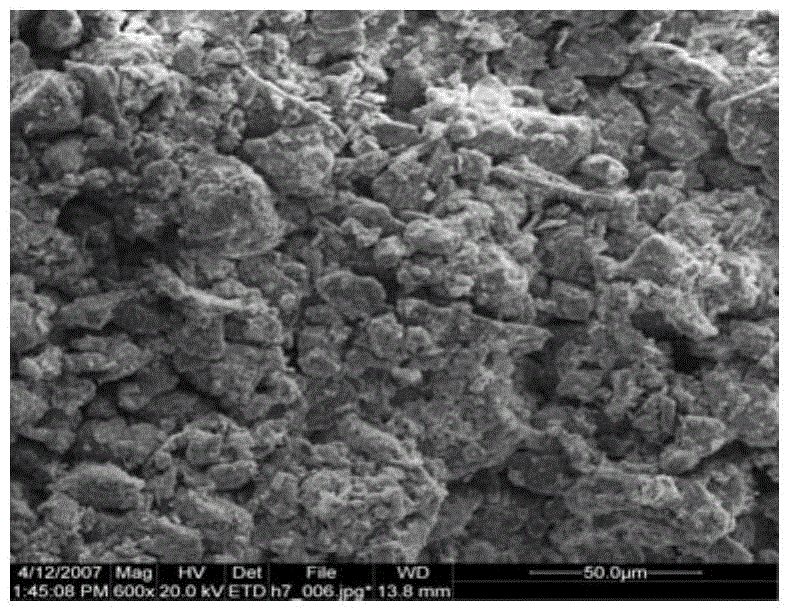

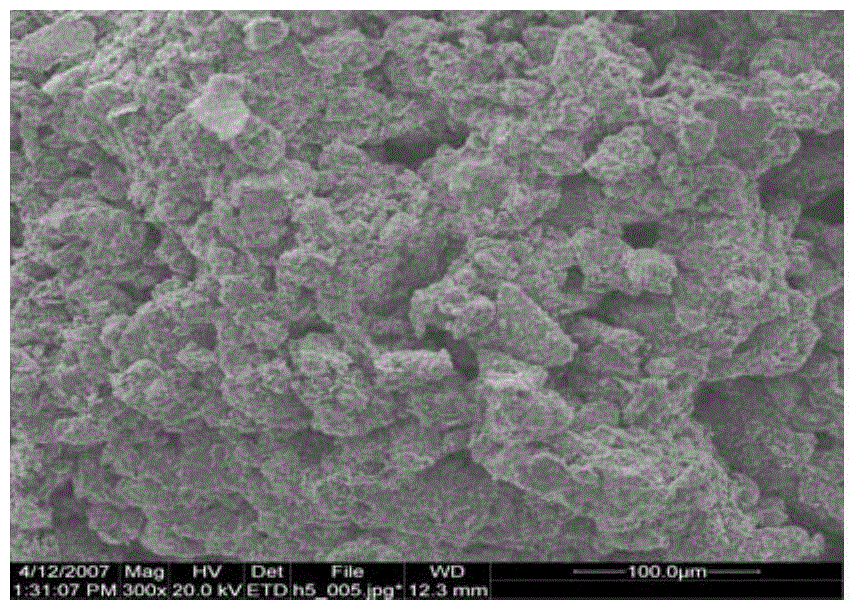

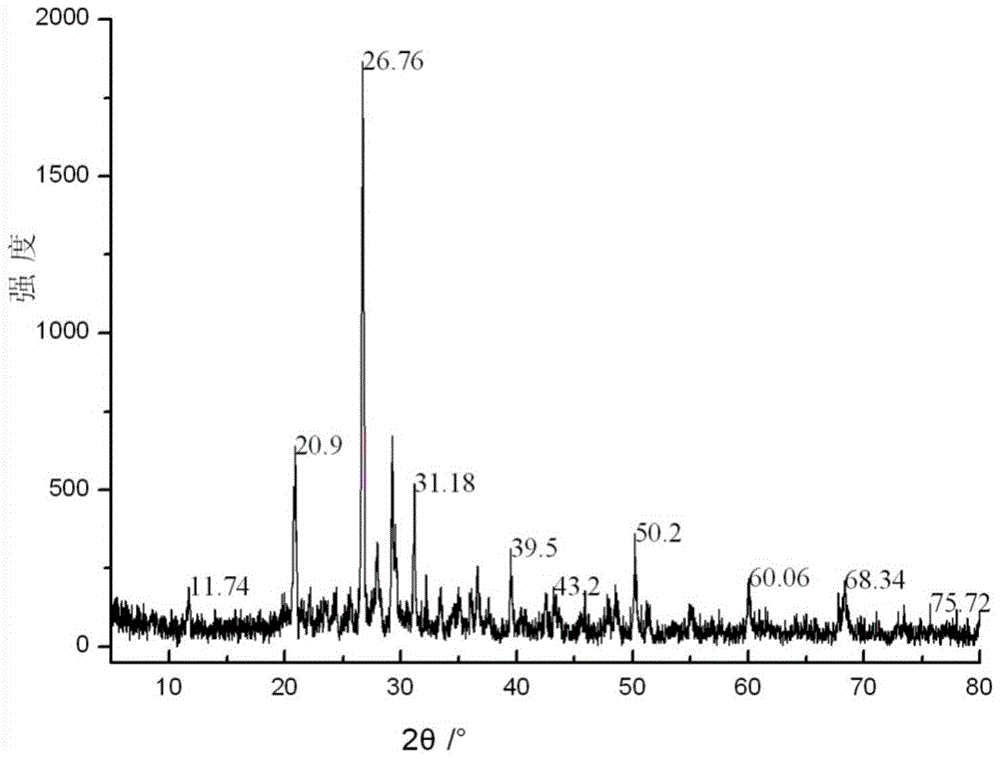

[0033] A kind of crisp powder mural protection reinforcing agent, described crisp powder mural reinforcing material includes TB-1, TB-2, TB-3 and TB-4 reinforcing agent, wherein, TB-1 reinforcing agent is every 1000 milliliters of ethanol Dissolve 150ml of tetraethyl orthosilicate in a colorless and clear solution, TB-2 reinforcement is a colorless and clear solution of 2 grams of oxalic acid and 2 milliliters of phosphoric acid dissolved in every 1000 milliliters of ethanol, TB-3 reinforcement is a colorless and clear solution in every 1000 milliliters of ethanol A colorless and clear solution of 5 grams of barium hydroxide of 100-200 nanometer level developed by a ball mill dissolved in milliliters of methanol, and the TB-4 reinforcing agent is a colorless and clear solution of 3 grams of sodium octaborate dissolved in 100 milliliters of water; The chemical raw materials mentioned above are industrial pure. Among them, the appropriate volume ratio of the four reagents TB1, T...

Embodiment 2

[0046] A kind of crisp powder mural protection reinforcing agent, described crisp powder mural reinforcing material includes TB-1, TB-2, TB-3 and TB-4 reinforcing agent, wherein, TB-1 reinforcing agent is every 1000 milliliters of ethanol Dissolve 250ml of tetraethyl orthosilicate in a colorless and clear solution, TB-2 reinforcement is a colorless and clear solution in which 5 grams of oxalic acid and 5 milliliters of phosphoric acid are dissolved in every 1000 milliliters of ethanol, and TB-3 reinforcement is a colorless and clear solution in every 1000 milliliters of ethanol A colorless and clear solution of 10 grams of barium hydroxide and 3 grams of polyethylene glycol (200 molecular weight) developed by a ball mill and 3 grams of polyethylene glycol (200 molecular weight) dissolved in milliliters of methanol, 5 grams of TB-4 reinforcement is dissolved in 100 milliliters of water A colorless clear solution of sodium octaborate; the chemical raw materials are all technicall...

Embodiment 3

[0059] A kind of crisp powder mural protection reinforcing agent, described crisp powder mural reinforcing material includes TB-1, TB-2, TB-3 and TB-4 reinforcing agent, wherein, TB-1 reinforcing agent is every 1000 milliliters of ethanol Dissolve 200ml of tetraethyl orthosilicate in a colorless and clear solution, TB-2 reinforcement is a colorless and clear solution in which 3 grams of oxalic acid and 3 milliliters of phosphoric acid are dissolved in every 1000 milliliters of ethanol, and TB-3 reinforcement is a colorless and clear solution in every 1000 milliliters of ethanol A colorless and clear solution of 7 grams of barium hydroxide and 2.5 grams of polyethylene glycol (200 molecular weight) developed by a ball mill and 2.5 grams of polyethylene glycol (200 molecular weight) dissolved in milliliters of methanol, TB-4 reinforcement is dissolved in 100 milliliters of water 4 grams A colorless clear solution of sodium octaborate; the chemical raw materials are all technicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com