Pretreatment technique for decolorization of wastewater at middle plate of paper-making pulping

A pretreatment and wastewater technology, which is applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost, unreachable decolorization, high power consumption, etc., and achieve sustainable Improved biochemical properties, stable reaction process, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

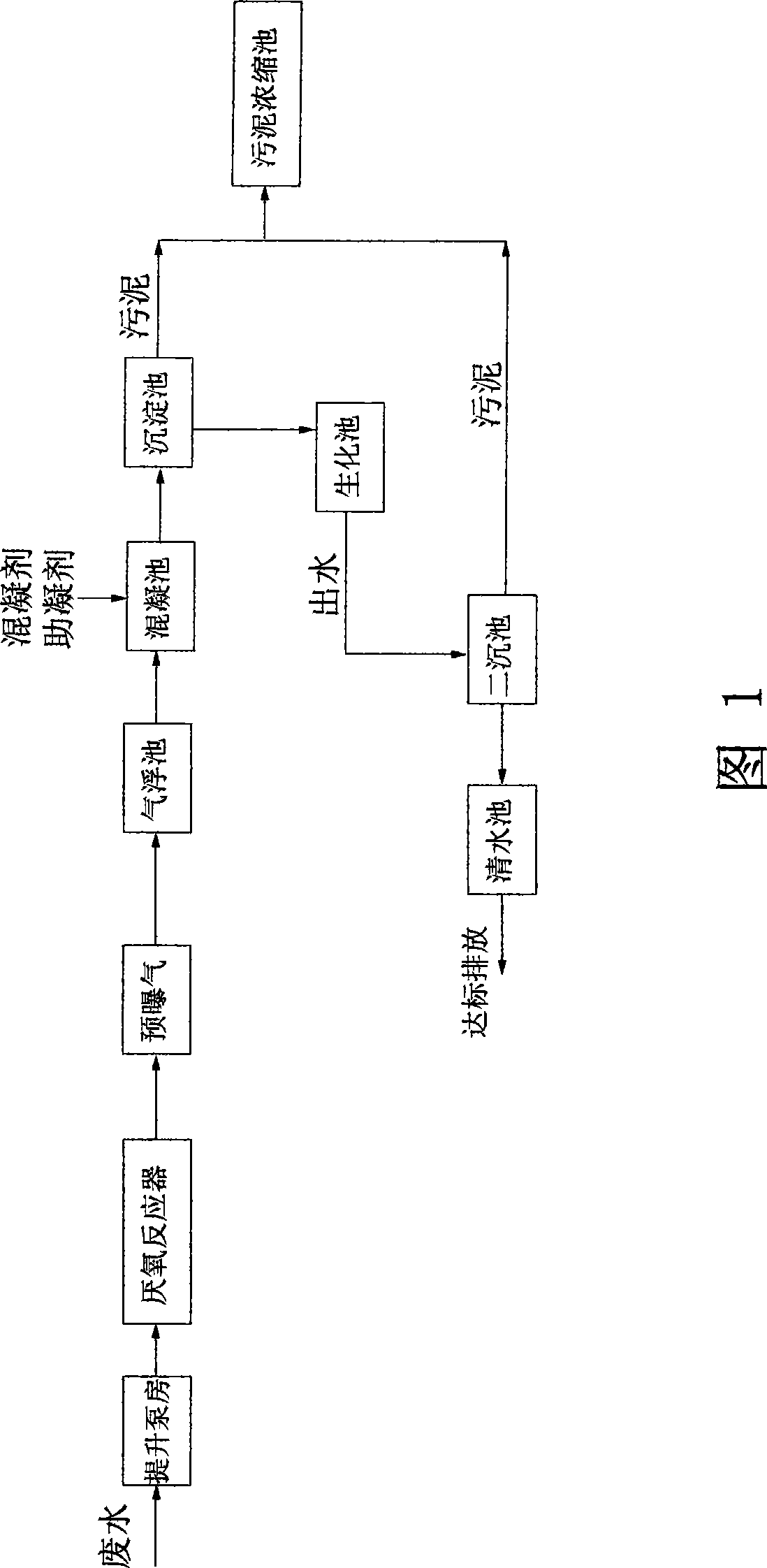

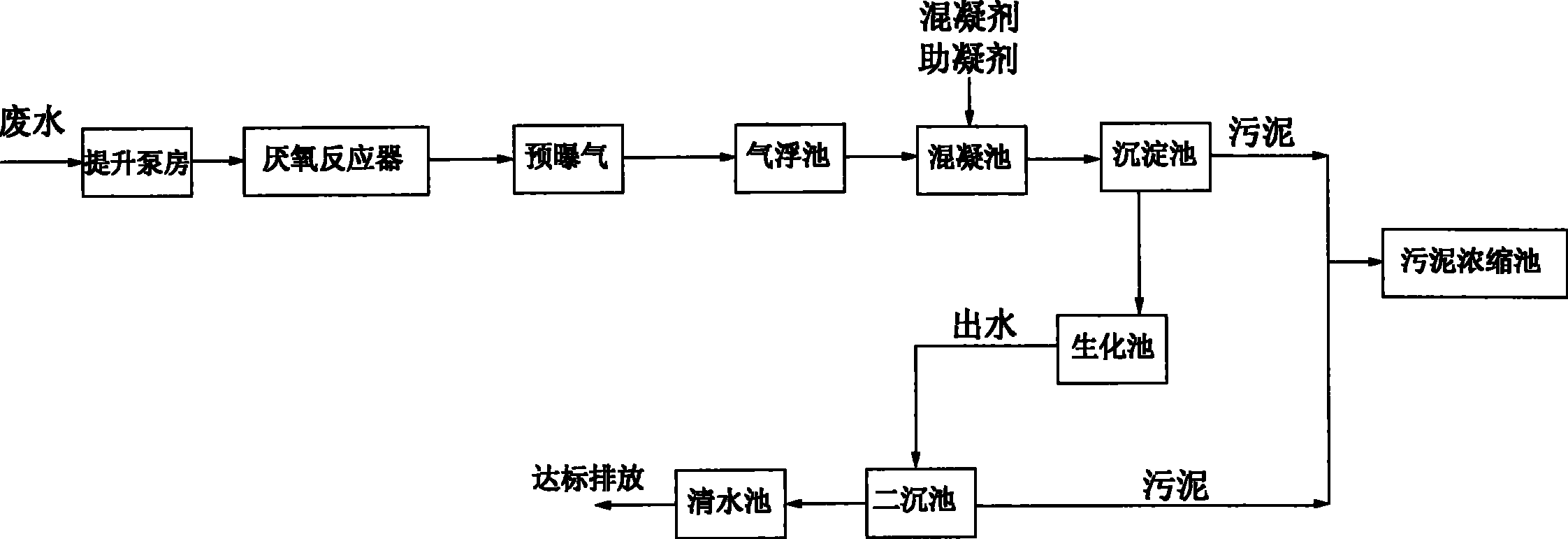

[0020] A pretreatment process for decolorizing waste water in the middle stage of papermaking pulping, comprising the following steps:

[0021] ①Introduce the above wastewater into an anaerobic reactor for anaerobic treatment, so that part of the biodegradable organic matter in the wastewater can be converted into methane and carbon dioxide, and the non-biodegradable lignin substances in the wastewater can be reduced;

[0022] ②Introduce the effluent treated in step ① into the coagulation tank, and add a compound coagulant into the coagulation tank to promote the coagulation of lignin substances in the wastewater;

[0023] ③Introduce the effluent treated in step ② into the sedimentation tank for mud-water separation.

[0024] An air flotation tank is added between step ① and step ②, so that the effluent of step ① is treated by the air flotation tank and then introduced into the coagulation tank; pre-aeration treatment is performed before the effluent of step ① is treated by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com