Polyurethane combined material, method for preparing polyurethane composite through polyurethane combined material, and application of prepared product

A combination of polyurethane material and polyether technology, which is applied in the field of polyurethane, can solve the problems of reducing the final mechanical properties of the product, the internal release agent is of little significance, and increasing the instability of the system, so as to achieve excellent storage stability and improve storage stability Sexuality, good release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

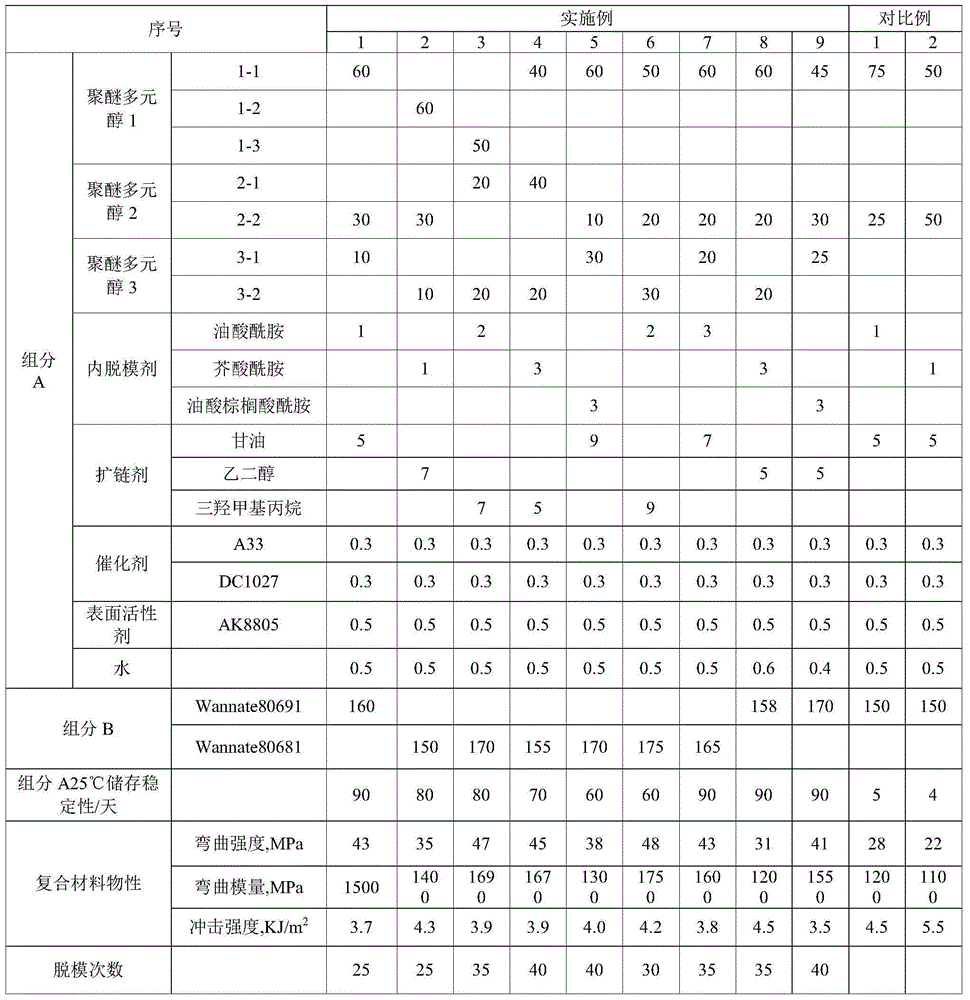

[0069] Examples 1-9: Isocyanate-reactive component A and isocyanate component B were prepared according to the formula in Table 1, and the storage stability of component A at 25° C. was investigated.

[0070] Preparation of composite materials: Keep the corresponding isocyanate reactive component A and isocyanate component B at 25±5°C respectively, attach the reinforcing material glass fiber to both sides of the paper honeycomb material, and evenly spray the isocyanate reactive component on the glass fiber Divide the mixture of A and isocyanate component B, and then put it into a mold for compression molding. The mold temperature is 120°C, and the pressing time is 110 seconds. After completion, it is taken out from the mold to obtain a polyurethane composite material. The properties of the composite materials are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com