Plant type gas-phase copper corrosion inhibitor and preparation method thereof

A copper corrosion inhibitor, plant-based technology, applied in the field of plant-type gas-phase copper corrosion inhibitor and its preparation, can solve the problems of high toxicity, complex process of gas-phase copper corrosion inhibitor, difficult degradation, etc., achieve aromatic smell, increase corrosion resistance Corrosion effect and stability, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of vapor phase copper corrosion inhibitor provided by the invention comprises the following steps:

[0028] (1) crush the garlic, and ultrasonically mix it with an appropriate amount of medical alcohol, preferably in a weight ratio of 1:1; carry out solid-liquid separation and retain the liquid to obtain the garlic extract;

[0029] (2) Grind the fragrant leaves, and ultrasonically mix them with an appropriate amount of medical alcohol, preferably in a weight ratio of 1:5; carry out solid-liquid separation and retain the liquid to obtain the fragrant leaf extract;

[0030] (3) The garlic extract prepared in step (1) and the bay leaf extract prepared in step (2) were mixed according to a weight ratio of 3:1 to prepare the plant-type vapor phase copper corrosion inhibitor.

[0031] The volatile organic compounds in the garlic extract are identified by headspace mass spectrometry, and contain 30%-50% dipropenyl trisulfide, 10%-30% dipropenyl disulfid...

Embodiment 1

[0042] A plant-type vapor-phase copper corrosion inhibitor is obtained by compounding 75% of garlic extract and 25% of bay leaf extract according to weight percentage.

[0043] The plant-type gas-phase copper corrosion inhibitor is prepared as follows: according to the weight ratio, 1 part of garlic is mashed and evenly mixed with 1 part of 75% ethanol solution, and filtered after ultrasonic extraction to obtain milky yellow garlic extract; according to the weight ratio, the 1 part of bay leaf is cut into pieces and mixed evenly with 5 parts of 75% ethanol solution, filtered after ultrasonic extraction to obtain green bay leaf extract; the plant-type gas-phase copper corrosion inhibitor combines 75% of garlic extract with 25% of Prepared by uniformly mixing the bay leaf extract.

[0044] The main components and weight content of its volatile matter: 16.56% dipropenyl trisulfide, 7.43% dipropenyl disulfide, 7.24% 1-oxo-4,6-diazacyclooctane-5-thione, 31.61% eucalyptol, 15.3% L-...

Embodiment 2

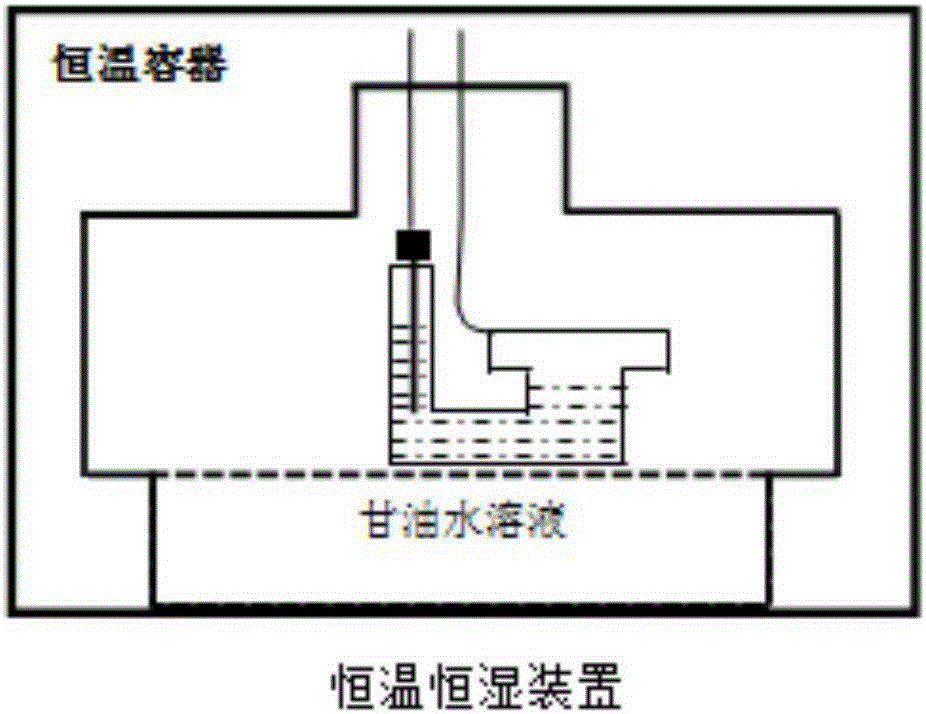

[0050] The copper sheet added with the plant-type vapor-phase copper corrosion inhibitor in Example 1 and Comparative Examples 1 and 2 was subjected to atmospheric corrosion measurement.

[0051] According to the method in Comparative Example 3, the plant-type vapor-phase copper corrosion inhibitors described in Example 1 and Comparative Examples 1 and 2 were respectively placed in the covered vessel described in Comparative Example 3, and the airtight container was first dried at 35°C Middle pre-filming 24h, after pre-filming, other conditions are consistent with comparative example 3. Two days later, the atmospheric corrosion of the copper sheet was measured, and the results are shown in Table 1.

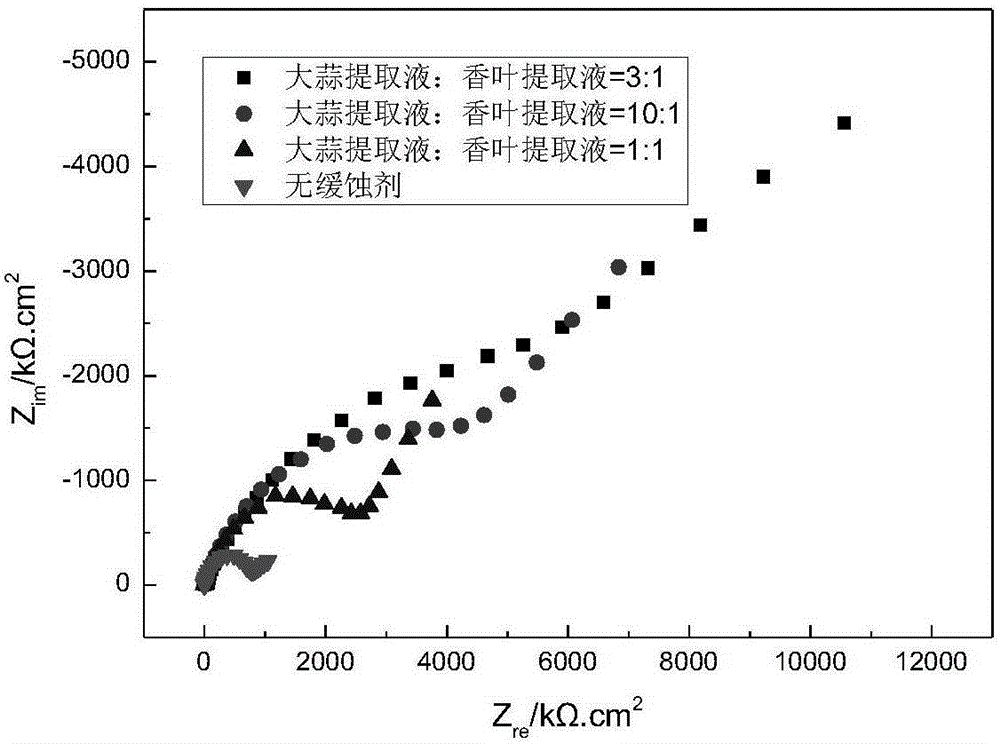

[0052] As can be seen from Table 1, the plant-type vapor-phase copper corrosion inhibitor described in Example 1 and Comparative Examples 1 and 2 all has a good corrosion inhibition effect, and the plant-type vapor-phase copper corrosion inhibitor described in Comparative Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com