A kind of cooked plum original flavor granule buccal tablet and its preparation method

A technology of granules and green plums, applied in the field of snack food, can solve problems such as being unsuitable for ordinary healthy consumers to eat in large quantities, requiring high production process and storage conditions, and difficult to guarantee product hygiene and quality, and improving nutritional value and efficacy, The effect of ensuring health value and improving the aroma and sourness of plum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

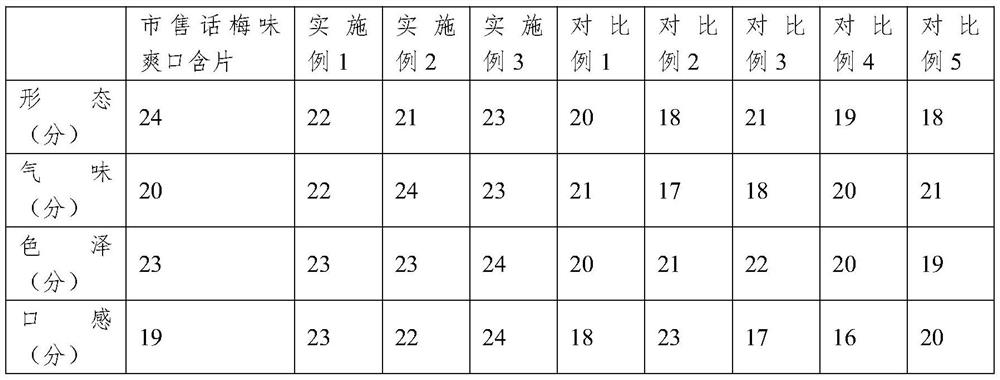

Embodiment 1

[0040] A kind of cooked plum original flavor granule buccal tablet, take 43.3% cooked plum powder, 30% plum meat granules, auxiliary materials (3% plum essence, 2.2% salt, 0.5% sucrose powder, 2% sucralose, 2.1% DL-apple acid, 5% glucose, 2% magnesium stearate, 5.4% lactose, 4.5% mannitol) mixed and granulated, and then compressed into tablets;

[0041] The present embodiment provides the preparation method of granule buccal tablet:

[0042] (1) Greengage essence production: take 5 to 6 mature and complete greengages with hard flesh and green skin as the raw material for making plum essence, and use a pitting and flapping machine to perform pitting and cutting to remove the core of the greengage fruit; use a beater Fully crush and beat the greengage pulp for 10-30 minutes, add distilled water during the crushing process, the mass ratio of pulp and distilled water is 1:3; pass the juice with dregs through a 260-mesh filter bag and let it stand for 12 hours, take the clear juice...

Embodiment 2

[0049] A granule buccal tablet of cooked plum flavor, which contains 25% cooked plum powder, 15% plum meat granules, 2% hawthorn, 2.6% licorice, 1% roselle, 9.5% mulberry, 18% orange peel, 5.1% mint leaves, Excipients (0.5% plum essence, 0.2% salt, 1.9% sucrose powder, 0.1% sucralose, 0.2% DL-malic acid, 4% glucose, 1% magnesium stearate, 5.9% lactose, 8% mannitol) mixing Granulated, then compressed into tablets;

[0050] The present embodiment provides the preparation method of granule buccal tablet:

[0051] (1) Greengage essence production: take 5 to 6 mature and complete greengages with hard flesh and green skin as the raw material for making plum essence, and use a pitting and flapping machine to perform pitting and cutting to remove the core of the greengage fruit; use a beater Fully crush and beat the greengage pulp for 10-30 minutes, add distilled water during the crushing process, the mass ratio of pulp and distilled water is 1:3; pass the juice with dregs through a ...

Embodiment 3

[0059] A kind of cooked plum original flavor granule buccal tablet, take 36% cooked plum powder, 20% plum meat granule, 3.1% hawthorn, 2% licorice, 4.2% roselle, 3% mulberry, 4.7% orange peel, 0.3% mint leaf, Excipients (3% plum essence, 2.2% salt, 0.5% sucrose powder, 2% sucralose, 2.1% DL-malic acid, 5% glucose, 2% magnesium stearate, 5.4% lactose, 4.5% mannitol) mixed Granulated, then compressed into tablets;

[0060] The present embodiment provides the preparation method of granule buccal tablet:

[0061] (1) Greengage essence production: take 5 to 6 mature and complete greengages with hard flesh and green skin as the raw material for making plum essence, and use a pitting and flapping machine to perform pitting and cutting to remove the core of the greengage fruit; use a beater Fully crush and beat the green plum pulp for 10-30 minutes, add distilled water and pulp to mix and beat during the crushing process, the mass ratio of pulp and distilled water is 1:4; pass the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com