Method for controlling content of hydrogen in zinc dissolving tank for electro-galvanizing and zinc dissolving system

A technology of electrogalvanizing and zinc dissolving, which is applied in the direction of electrolysis, electrolysis components, cells, etc., can solve problems such as contact area contradictions, achieve the effects of reducing hydrogen production, controlling hydrogen concentration, and ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

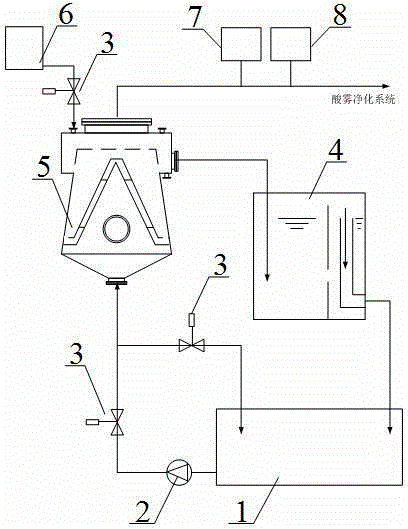

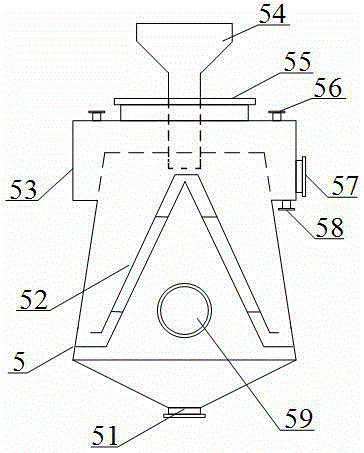

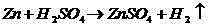

[0029] Such as figure 1 , the embodiment of the present invention provides a method for controlling the hydrogen content in the electro-galvanized zinc-dissolving tank, the method is specifically: a hydrogen concentration detector 7 is installed on the mist discharge pipeline connected to the zinc-dissolving tank 5 to monitor the zinc-dissolving tank 5 in real time The concentration of hydrogen in the tank; a supporting plate 52 with an inclined part is set in the zinc melting tank 5, and the supporting plate 52 is used to carry zinc particles, and at least a plurality of through holes are opened on the inclined part, so that electroplating The liquid overflows to the top of the supporting plate 52 to react with the zinc particles or make the electroplating solution return to the bottom of the supporting plate 52. The supporting plate 52 should divide the inner space of the zinc-dissolving tank 5 into upper and lower parts, and the zinc particles are fed into the zinc-dissolvi...

Embodiment 2

[0035] Such as Figure 1-Figure 2 , the embodiment of the present invention also provides a zinc dissolving system, including a zinc dissolving tank 5, an electroplating solution circulation tank 1 and an electroplating solution precipitation tank 4, the bottom of the zinc dissolving tank 5 is provided with a liquid inlet 51, and the top is open and sleeved with a ring Overflow groove 53, on this annular overflow groove 53 (bottom or sidewall) offer liquid outlet 57, the inlet end of electroplating solution precipitation tank 4 communicates with this liquid outlet 57, the outlet end of electroplating solution precipitation tank 4 is connected with The inlet end of the electroplating solution circulation tank 1 is connected, and an electroplating solution supply pipeline and an electroplating solution return pipeline are connected in parallel between the outlet end of the electroplating solution circulation tank 1 and the liquid inlet 51, and the electroplating solution supply p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com