Exhaust gas discharge system for cyanide plating tank

A waste gas discharge system and cyanide technology, applied in chemical instruments and methods, dispersed particle filtration, combined devices, etc., can solve problems such as cyanide-containing electroplating waste gas pollution, and achieve the effects of solving pollution problems, reducing operating costs, and reducing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

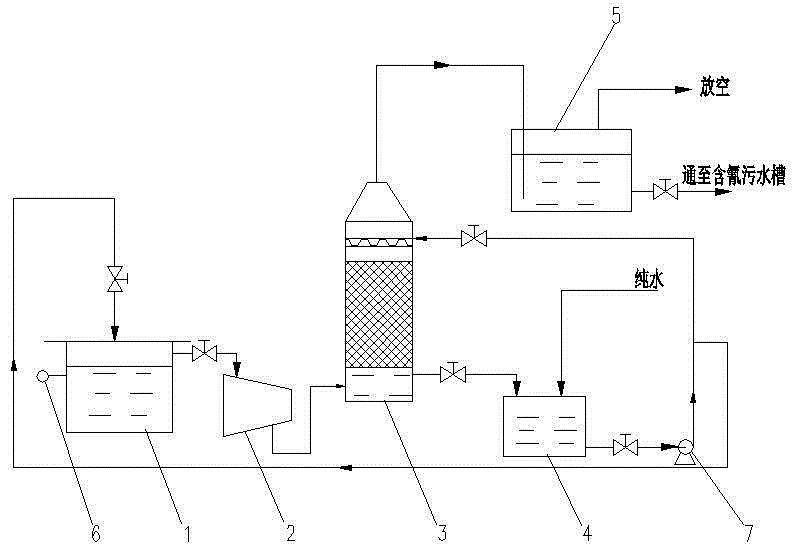

[0016] Embodiment 1: A kind of exhaust gas discharge system of cyanide plating tank.

[0017] Such as figure 1 As shown, the system includes a cyanide plating tank 1, a fan 2, a cyanide mist recovery tower 3, a recovery tank 4 and a reprocessing tank 5; the side of the cyanide plating tank 1 is provided with a gas-collecting outlet at 12 cm below the notch; the cyanide mist recovery A filter layer is provided in the middle of tower 3, a gas outlet is provided at the top, and a liquid outlet is provided at the bottom. The gas-gathering outlet on the side of the cyanide plating tank 1 is connected to the lower part of the cyanide mist recovery tower 3 through the gas-gathering pipeline, and the fan 2 is arranged on the gas-gathering pipeline; the gas outlet at the top of the cyanide mist recovery tower 3 is connected to the reprocessing tank 5 through the gas pipeline The bottom of the cyanide mist recovery tower 3 is connected to the recovery tank 4 through the recovery pipel...

Embodiment 2

[0018] Embodiment 2: Another exhaust gas discharge system for a cyanide plating tank.

[0019] There is a gas-collecting outlet on the side 15cm below the notch of the cyanide plating tank. All the other are identical with embodiment 1.

Embodiment 3

[0020] Embodiment 3: Yet another exhaust gas discharge system for a cyanide plating tank.

[0021] There is a gas-collecting outlet on the side 10cm below the notch of the cyanide plating tank. All the other are identical with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap