Exterior wall external heat insulation system added with glass fiber grid inorganic light aggregate mortar

An inorganic lightweight aggregate and external wall thermal insulation technology, which is applied in thermal insulation, climate change adaptation, building components, etc., can solve problems such as easy falling off, hollowing and cracking, etc., to achieve simple and easy construction, improve construction quality, and overcome falling off. The effect of the disadvantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described in conjunction with the following examples.

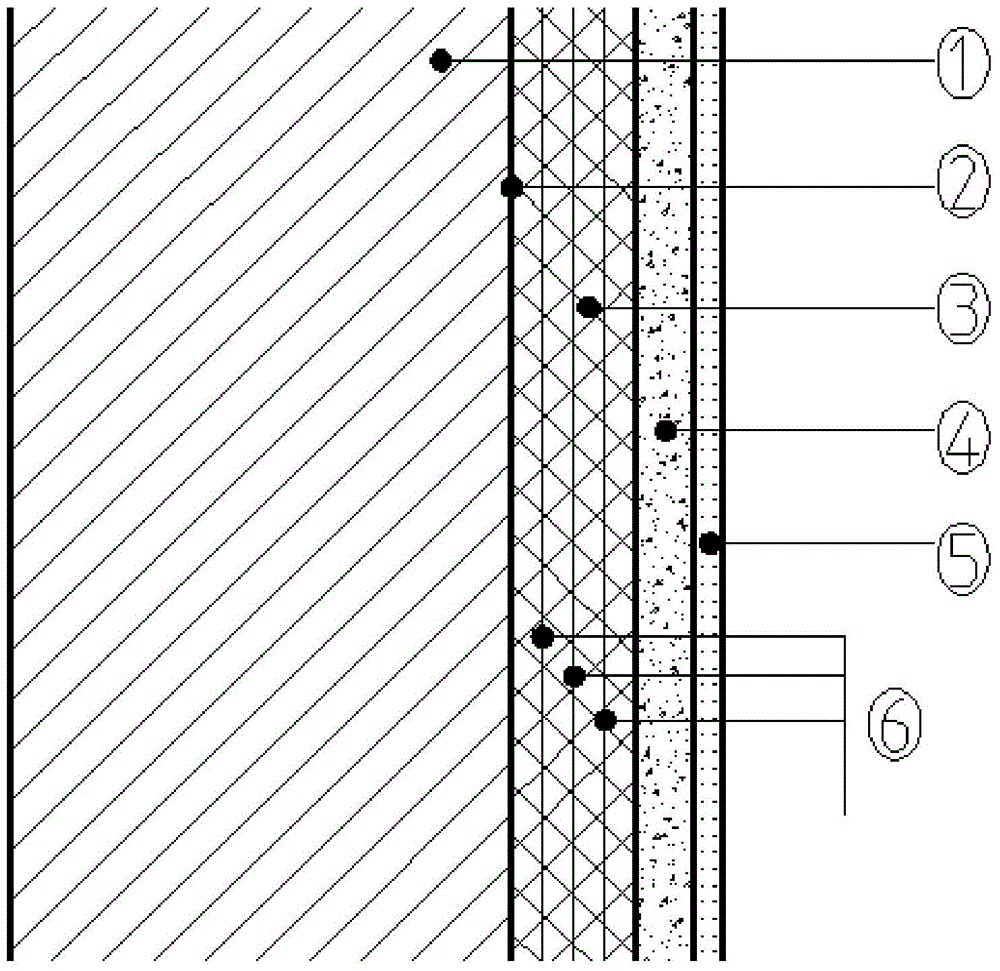

[0022] An external wall thermal insulation system added with glass fiber mesh inorganic light aggregate mortar, suitable for the base 1 of walls including concrete walls and various masonry walls, such as figure 1 As shown, it includes interface layer 2, thermal insulation layer 3, anti-crack surface layer 4 and finishing layer 5 arranged sequentially from inside to outside. The insulation layer 3 is formed by layering and painting, and glass fiber nets 6 are laid between each layer of insulation layers 3 .

[0023] In this embodiment, preferably, the insulation layer 3 is provided with 4 layers, and a glass fiber mesh 6 is laid on each layer of insulation layer 3; Net 6; After finishing the second layer of thermal insulation layer 3, the second layer of fiberglass mesh 6 is laid; after the third layer of thermal insulation layer 3 is constructed, the third layer of fiberglass mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap