A cylinder body self-cooling structure of a swash plate plunger pump

A swash plate type plunger pump, self-cooling technology, applied in the direction of variable volume pump parts, parts of pumping devices for elastic fluids, pumps, etc. It can improve the cooling efficiency and reliability, suppress the oil agitation and heat, and improve the oil flow direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the above-mentioned features and advantages of the present invention more obvious and easy to understand, the following specific embodiments are given and the accompanying drawings are described in detail as follows.

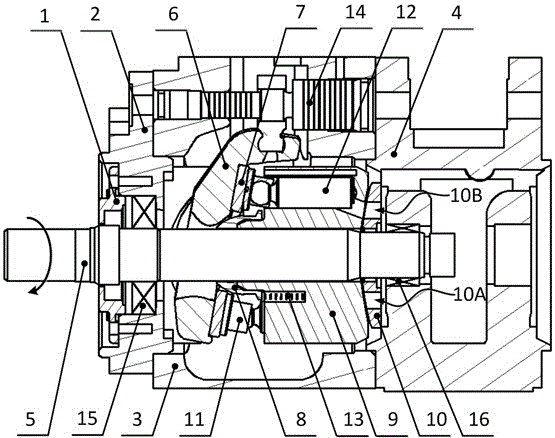

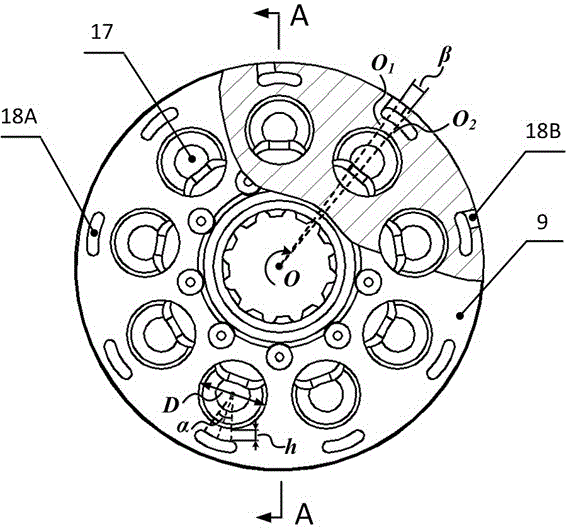

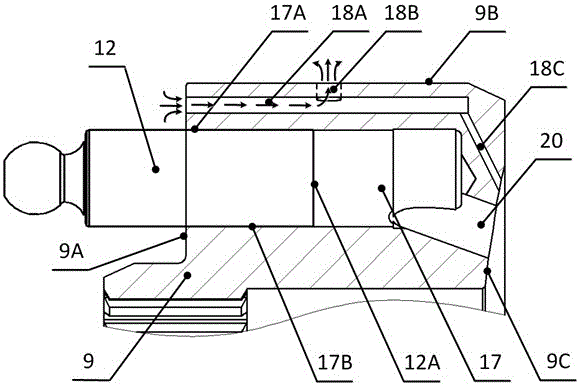

[0039] figure 1A schematic diagram schematically showing the internal structure of an embodiment of the present invention. The swash plate axial piston pump with cylinder body self-cooling structure consists of end cover 1, pump cover 2, front pump body 3, middle pump body 4, drive shaft 5, swash plate 6, bottom plate 7, spherical bushing 8, The cylinder block 9, the valve plate 10, the sliding shoe 11, the plunger 12, the cylinder block spring 13, the swash plate controller 14, the ball bearing 15, the needle roller bearing 16 and other parts are composed. The pump casing consists of a pump cover 2, a front pump body 3, and a middle pump body 4. The drive shaft 5 runs through the pump casing front and rear, and is supported by a ball b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com