Multifunctional self-locking nut and manufacturing method thereof

A technology of self-locking nuts and manufacturing methods, applied to nuts, screws, bolts, etc., to achieve the effects of simple structure, improved material utilization, and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

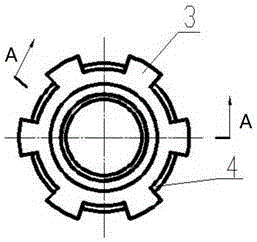

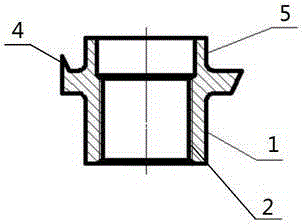

[0015] Embodiments of the invention: see figure 1 and figure 2 , a multifunctional self-locking nut of the present invention, comprising a nut body 1 , The lower end of the nut body 1 is provided with an internal thread 2, and the upper end of the nut body 1 is provided with a flaring section 5. On the outer wall of the nut body 1, 6 external teeth 3 are uniformly arranged, and between adjacent external teeth 3 There is an upwardly protruding riveting surface 4, and the cross-section of the riveting surface 4 is a right triangle that gradually becomes thinner from bottom to top.

[0016] At the same time, the present invention also provides a method for making the above-mentioned multifunctional self-locking nut. In the method, firstly, the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com