Photoelectric near electric field scanner

A near-field scanning device, an optoelectronic technology, applied in the direction of electromagnetic field characteristics, etc., can solve the problems of complicated observation recording and data analysis, inflexible control methods, spatial electromagnetic interference, etc., and achieve vivid and variable resolution of three-dimensional field strength data. The effect of shortening the rate and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

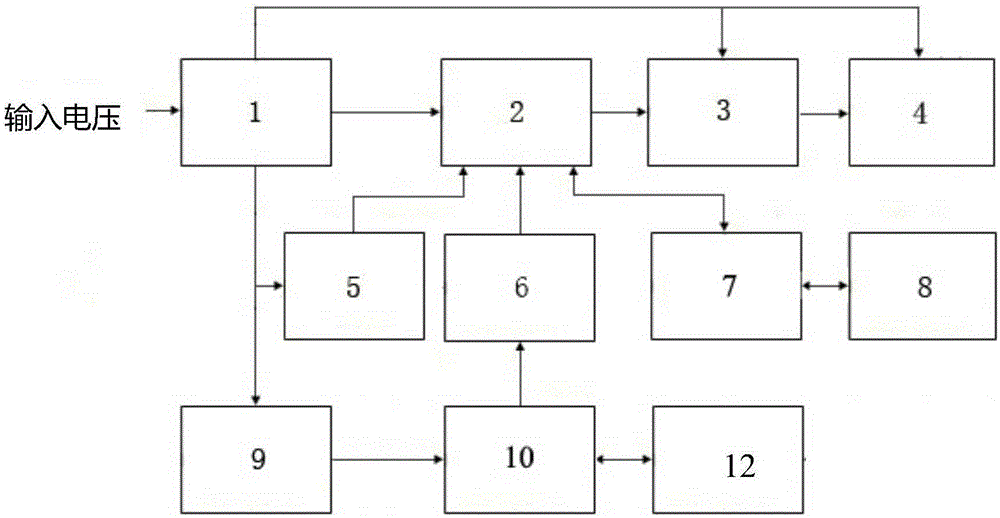

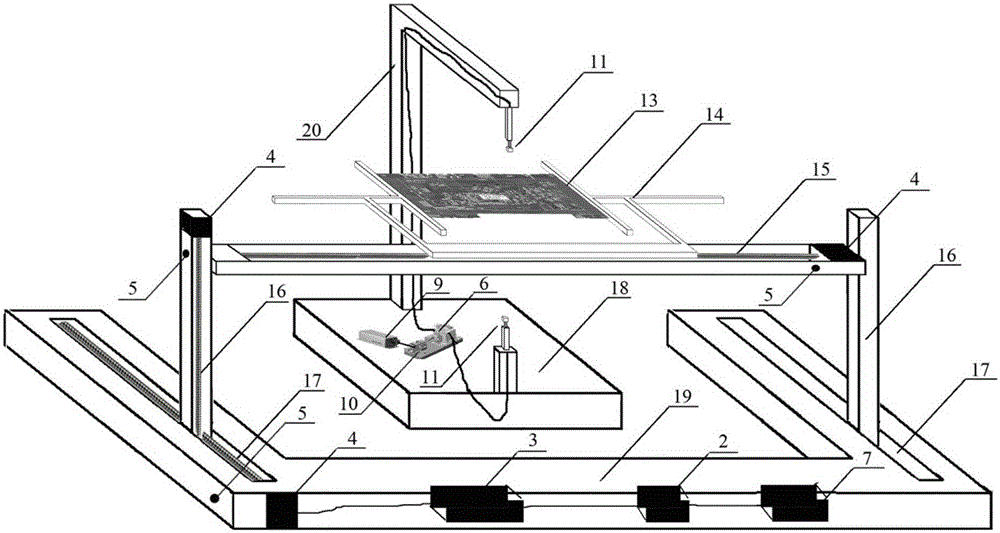

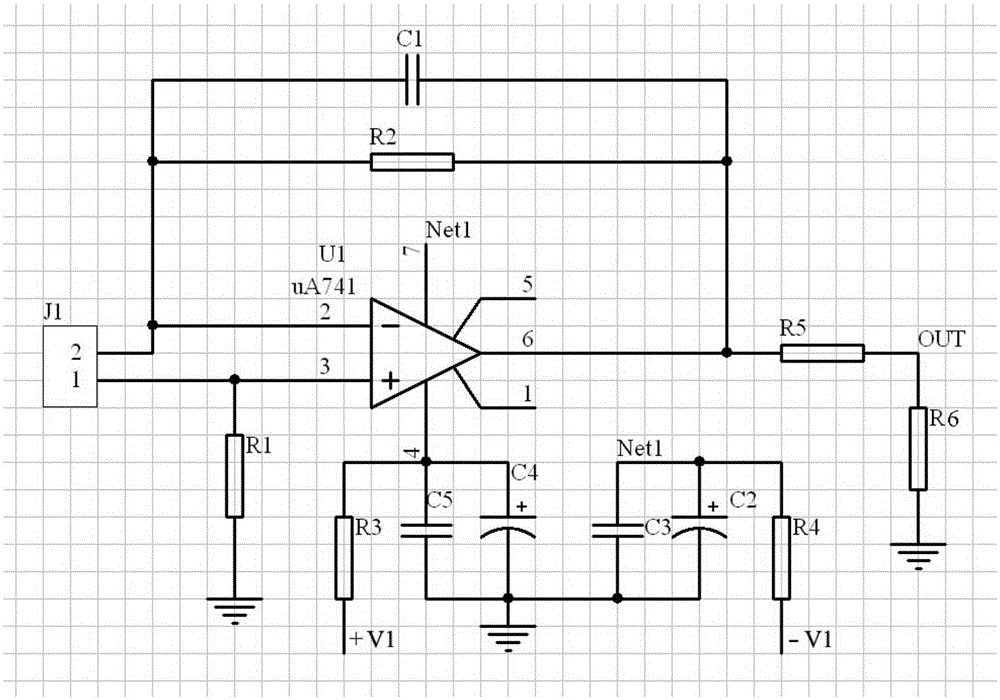

[0035] The photoelectric electric field near-field scanner of this embodiment according to figure 1 , figure 2 and image 3 The assembly structure of the shown embodiment includes an electric field near-field scanning device 12, a power supply 1, a controller 2, a drive module 3, three stepper motors 4, a three-way position sensor 5, a signal processing circuit 6, and a 485 bus communication module 7, Host computer 8, semiconductor laser 9 and optical circuit 10; the input voltage of power supply 1 is AC 220 volts, and the output of power supply 1 is provided with three circuits of DC 24V3A, DC positive 5V2A and DC negative 5V2A, among which power supply 1 outputs DC 24V3A to the drive module 3 and three stepper motors 4 supply power, power supply 1 outputs DC positive 5V2A and DC negative 5V2A to supply power to op amp uA741, power supply 1 outputs 5V2A to supply power to controller 2, three-way position sensor 5, semiconductor laser 9 and signal processing circuit 6 , thr...

Embodiment 2

[0046] In the photoelectric electric field near-field scanner of the present embodiment, except that the distance between the two optical fiber crystal probes 11 is 1 cm up and down, the adjustable range of the upper and lower probe adjustment arms 20 with a scale is 1 cm, and the fixed frame of the circuit board to be tested is 1 cm. 14 can fix the circuit board 13 to be tested with a width of 1 cm, and the rail movement range of the X-axis guide rail 15, the Y-axis guide rail 16 and the Z-axis guide rail 17 is 1 cm, and the others are the same as in Embodiment 1.

Embodiment 3

[0048] In the photoelectric electric field near-field scanner of the present embodiment, except that the distance between the two fiber crystal probes 11 is 50cm up and down, the adjustable range of the upper and lower probe adjustment arms 20 with a scale is 50cm, and the fixed frame of the circuit board to be tested is 50cm. 14 can fix the circuit board 13 to be tested with a width of 50cm, and the rail movement range of the X-axis guide rail 15, the Y-axis guide rail 16 and the Z-axis guide rail 17 is 60cm, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com