CBB82S type high current resistant long life polypropylene film capacitor

A polypropylene film and capacitor technology, applied in the direction of film/thick film capacitors, laminated capacitors, wire wound capacitors, etc., can solve the problems of instability, reduced current resistance parameters, poor consistency, etc., and achieve stable and reliable insulation resistance, The effect of increasing the current resistance characteristics and overcoming severe defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

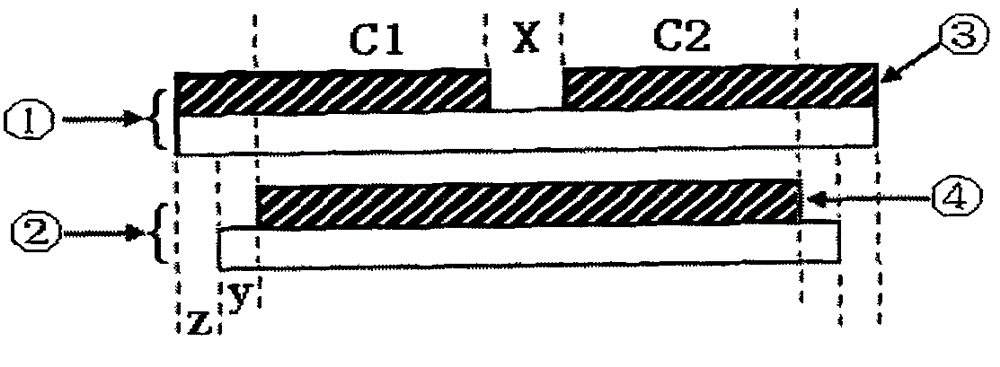

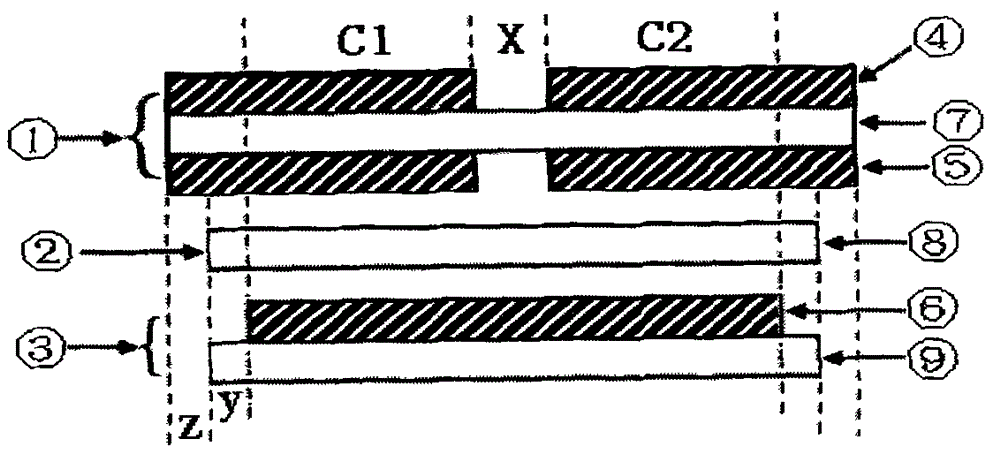

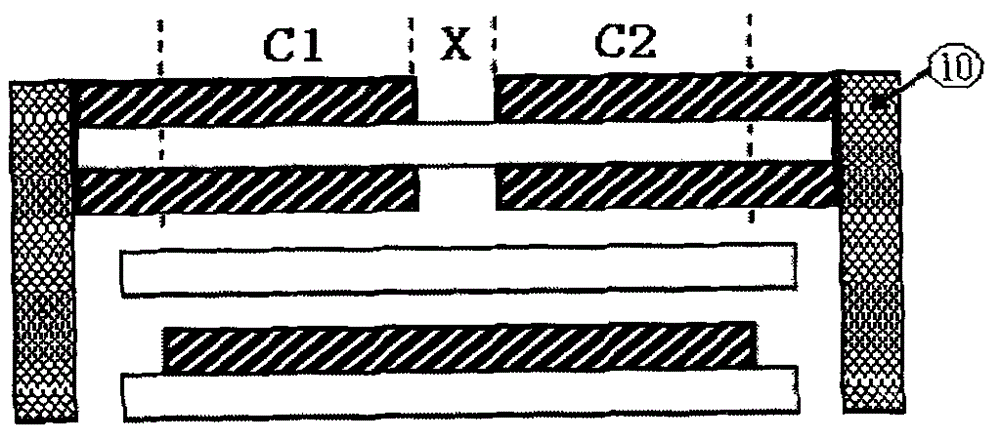

[0075] Figure 4 It is a transverse sectional structure diagram of the patent implementation example of the present invention, in Figure 4 In the APHMD double-sided aluminum plating, the metallized polypropylene high temperature film is used, see Figure 4 ①. And add a layer of PPH polypropylene high temperature film under the double-sided plating, see Figure 4 ② in. Under the PPH film, add a layer of APHT single-sided double-edge polypropylene high-temperature film, see Figure 4 ③ in. Due to the presence of edge x in the double-sided coated polypropylene film (the size of the edge x is different according to the rated voltage), two capacitors C1 and C2 are formed, and C1 and C2 are connected by APHT's low square resistance aluminum metallization coating C2 is connected in series. The APHT and PPH used were of equal width, aligned, 1 mm narrower than the APHMD, and centered with the APHMD.

[0076] Figure 5 is a longitudinally expanded structure diagram of the pate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com