Method for manufacturing rigid-flex PCB (printed circuit board)

A technology for rigid-flex boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, structural connection of printed circuits, printed circuit components, etc., which can solve problems such as easy delamination, weak bonding force, and bad white spots on the board surface, and achieve reduction Production cost, high binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

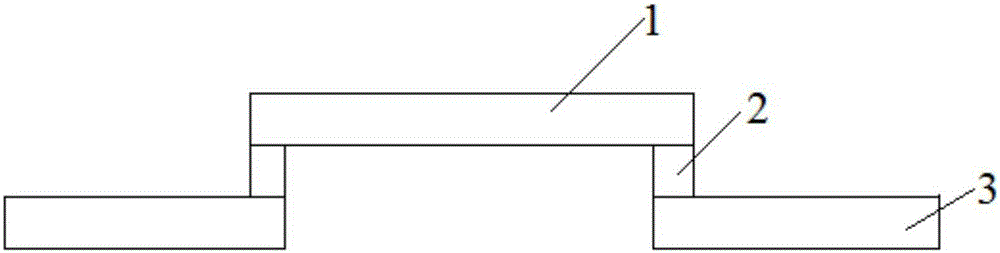

[0027] This embodiment provides a method for manufacturing a rigid-flex board, which includes the following steps:

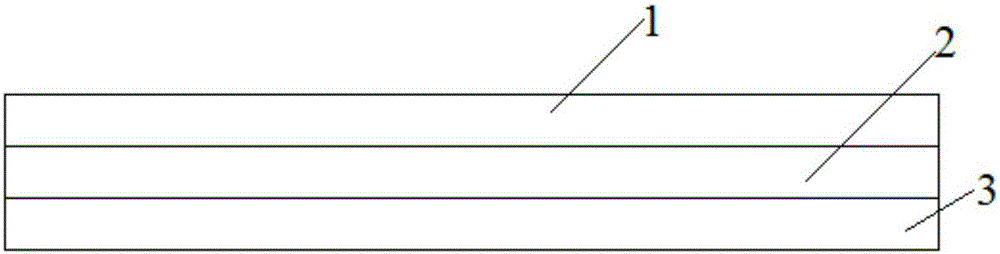

[0028] S1. Cutting the copper foil 4, cutting the copper foil 4 according to the predetermined size, keeping the copper foil 4 flat and without wrinkles when cutting the material;

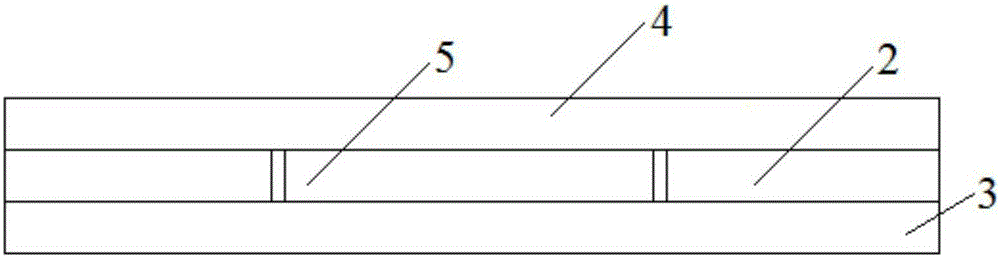

[0029] S2, the copper foil 4 is pasted with a cover film 5, and the middle part of the rough surface of the cut copper foil 4 is covered with a cover film 5. The cover film is a DuPont FR0110 cover film, which is a polyimide film with a thickness of 25 μm The adhesive layer and the film layer with a thickness of 25 μm, the adhesive layer is bonded to the surface of the copper foil 4, the film layer is located on the upper part of the adhesive layer and bonded with the adhesive layer; The cover film 5 is conducive to increasing the bonding force between the copper foil and the cover film 5, and the cover film 5 plays the role of protecting the circuit and preventing soldering;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com